Splenial bone implanting handle

A technology of implantation and bone clamping, which is applied in the field of medical devices, can solve the problems of increasing the difficulty of operation, not having timely fastening and loosening of bone blocks, etc., and achieves the effect of simple operation, high reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

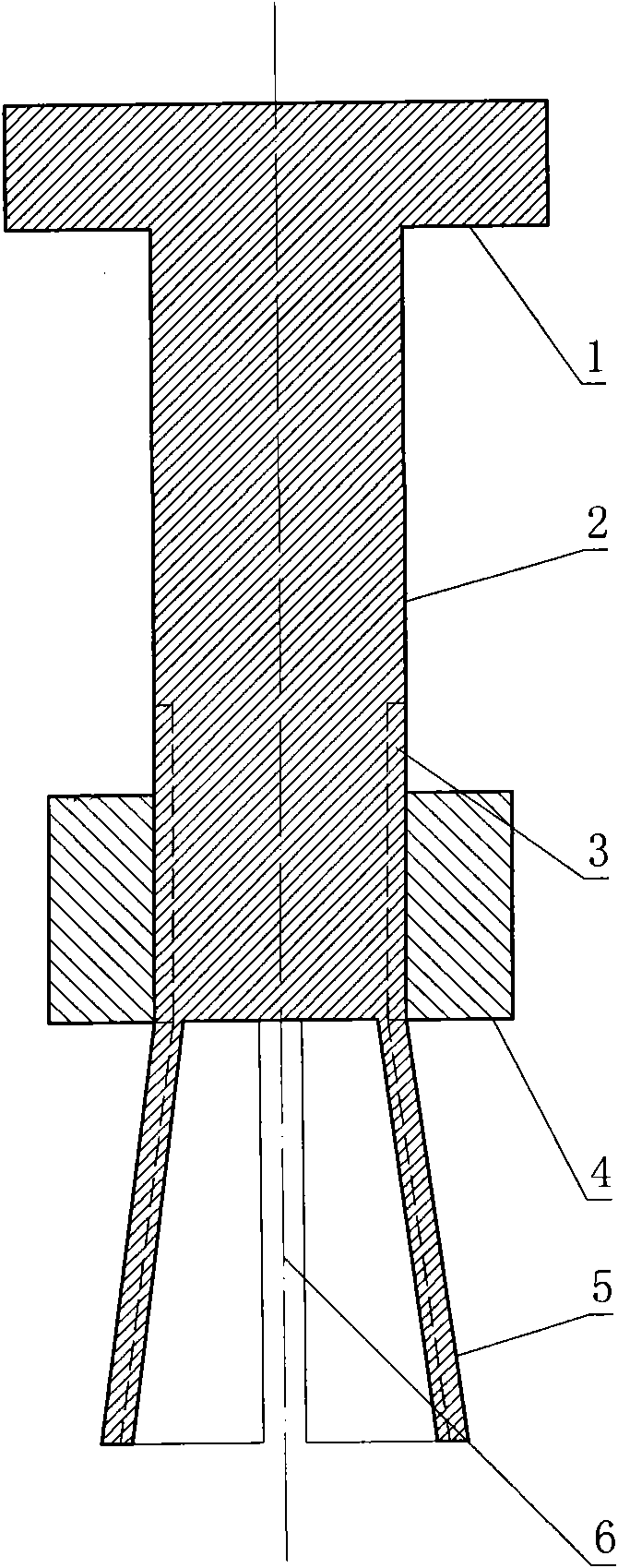

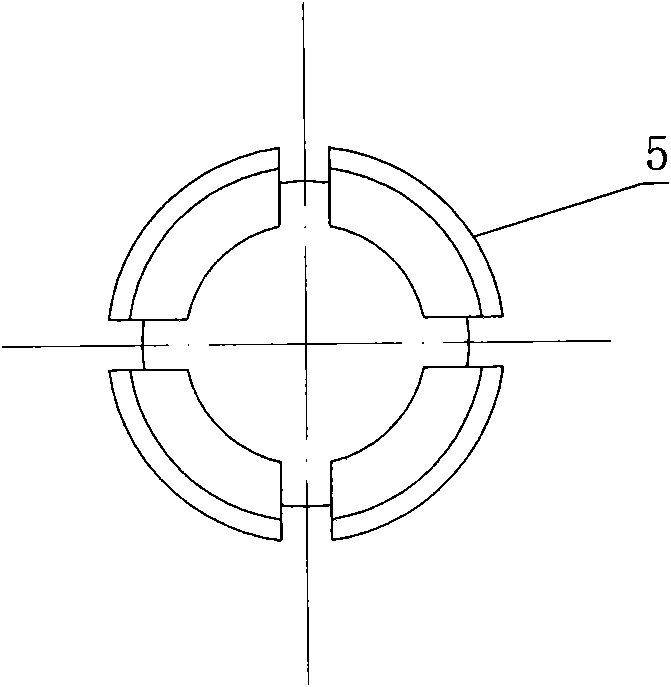

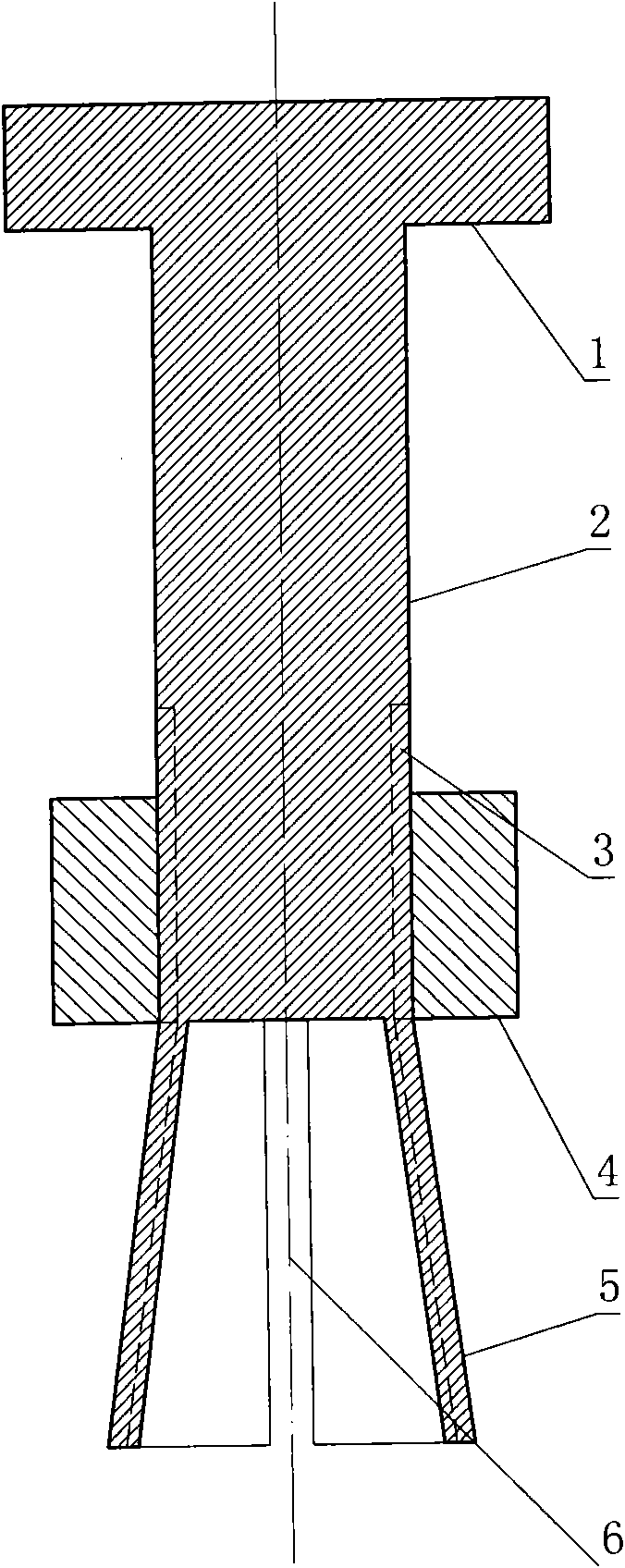

[0012] The bone clamp implant handle is composed of a stress cap 1, a handle 2, a thread 3, a fastening nut 4, a contraction tube 5 and a deformation seam 6. The handle 2 is a cylinder with threads 3 on the side wall at the lower end. The upper end of the handle 2 is a flat cylindrical stress cap 1 integrated with the handle 2. An integral cylindrical shrink tube 5 whose outer wall has a small taper at the top and a large taper at the bottom. There are threads on the outer wall of the shrink tube 5 . The outer wall of the shrink tube 5 has four evenly distributed deformation seams 6 , and the width of each deformation seam 6 is three times greater than the wall thickness of the deformation seams 6 . The junction of the handle 2 and the shrink tube 5 is covered with a fastening nut 4 threadedly combined with the handle 2 .

[0013] During operation, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com