Precision control method and device for adding micro-liquid

A precise control, trace liquid technology, applied in electrical program control, program control in sequence/logic controllers, etc., to save production costs, facilitate input of control parameters, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Taking flavoring in the cigarette production process as an example, the present invention is further described in detail:

[0039] Cigarette manufacturing process: It consists of three main processes: silk making (raw material processing), coiling (rolling molding), and packaging (packaged finished product); among them, flavoring is one of the main processes of cigarette silk making technology. Uniform application and saving raw materials are the key; this device can be used to control the addition of this flavor liquid material in the process of making cigarette shreds;

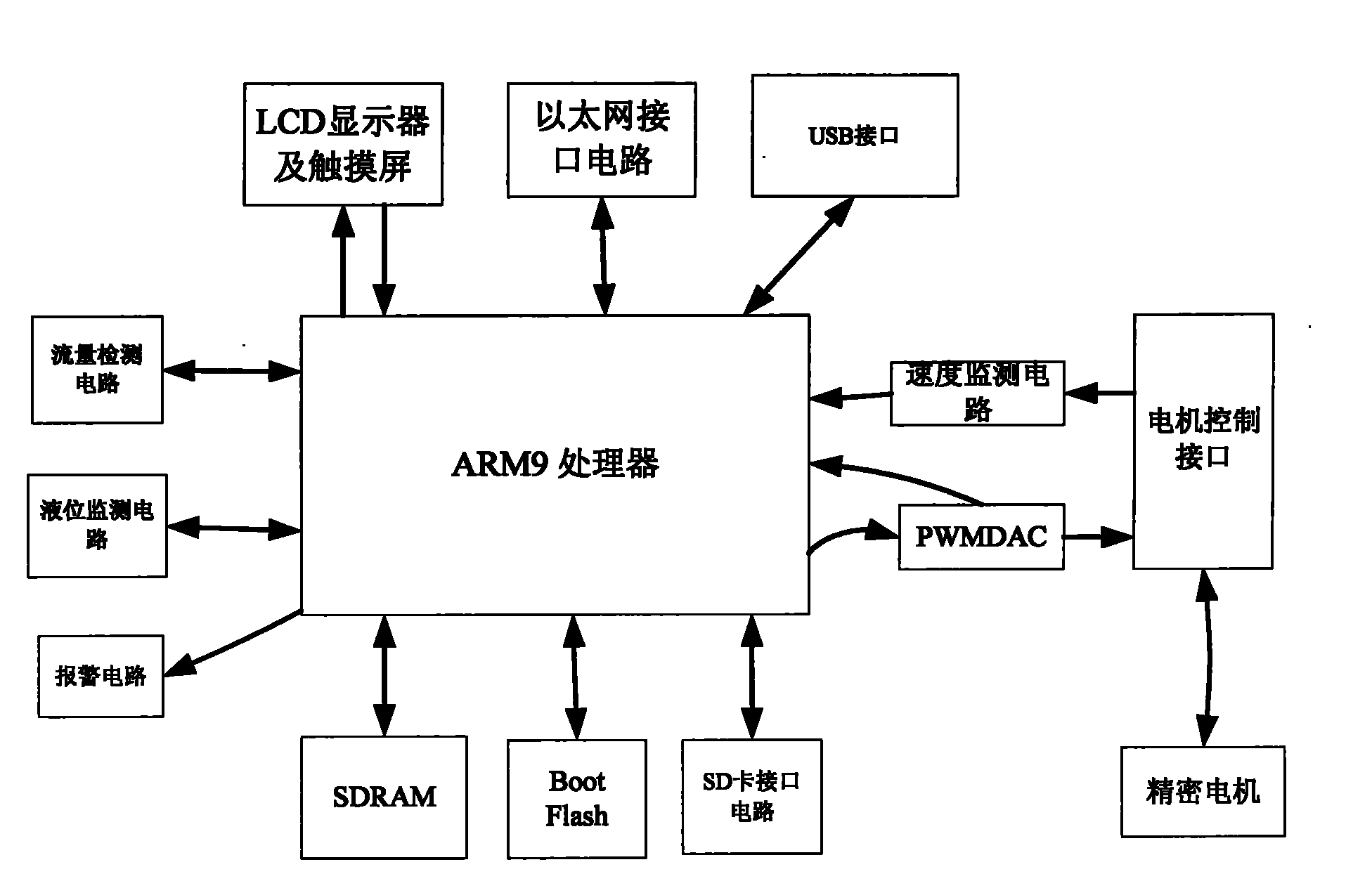

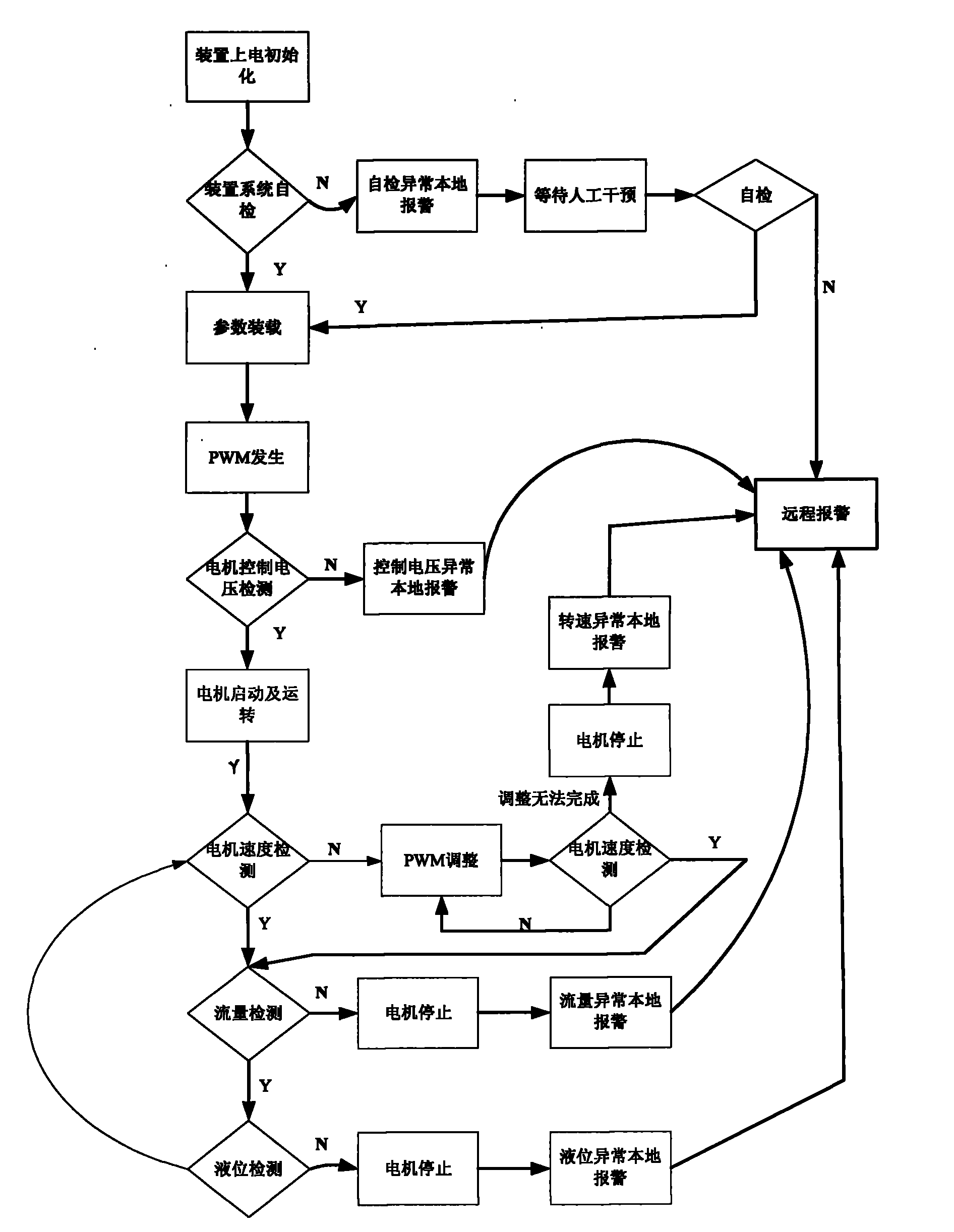

[0040] refer to figure 1 , when the control device of the present invention performs specific work, it is directly connected to the production line of cigarette shreds and the server of the control center of the production line to form a control system. The specific method is:

[0041] figure 1 The motor in the motor acts as a liquid essence flow rate control pump. The essence passes through its in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com