Non-contact type superconducting tape current-carrying capacity measuring device

A technology of superconducting tape and current-carrying capacity, applied in the field of superconducting engineering, can solve the problems of guiding, conveying and taking-up equipment, measuring the residual magnetism and unable to realize the current-carrying capacity test of the tape, etc. Effects of speed and measurement efficiency, design complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

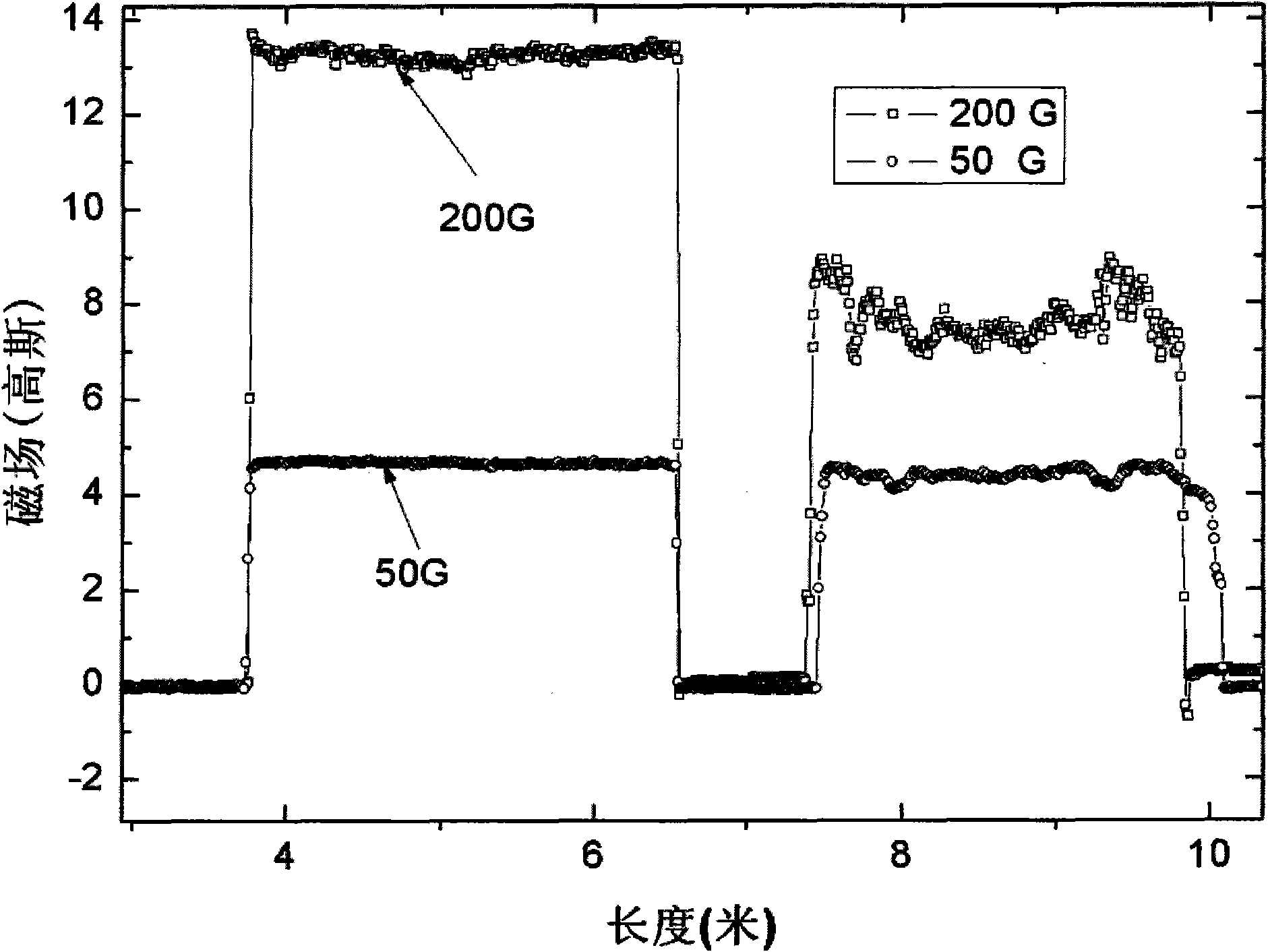

[0025] The working principle, measurement process and test results of the non-contact superconducting strip current-carrying capacity measurement device based on the single magnetic circuit method will be described in detail below in conjunction with the accompanying drawings and embodiments.

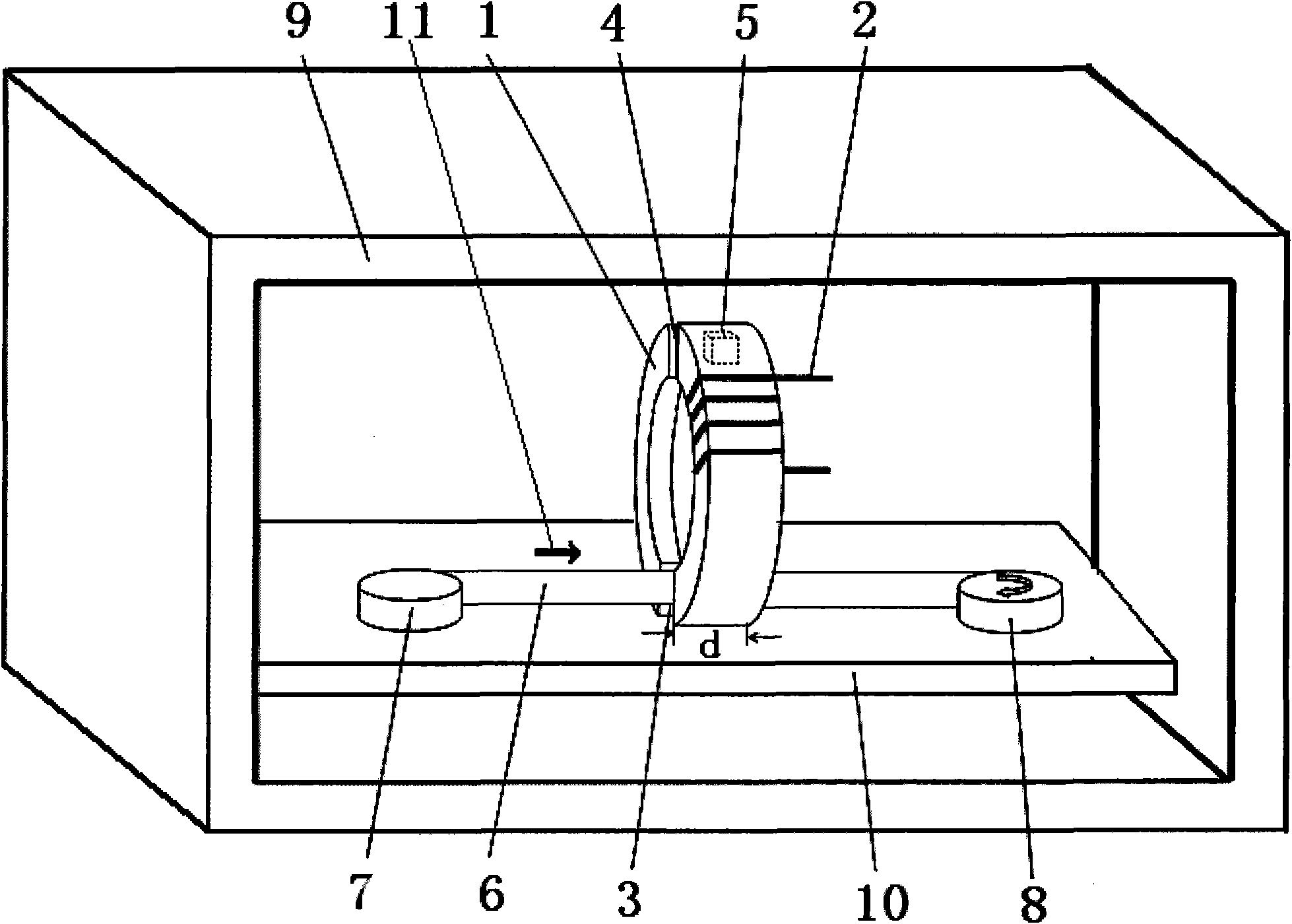

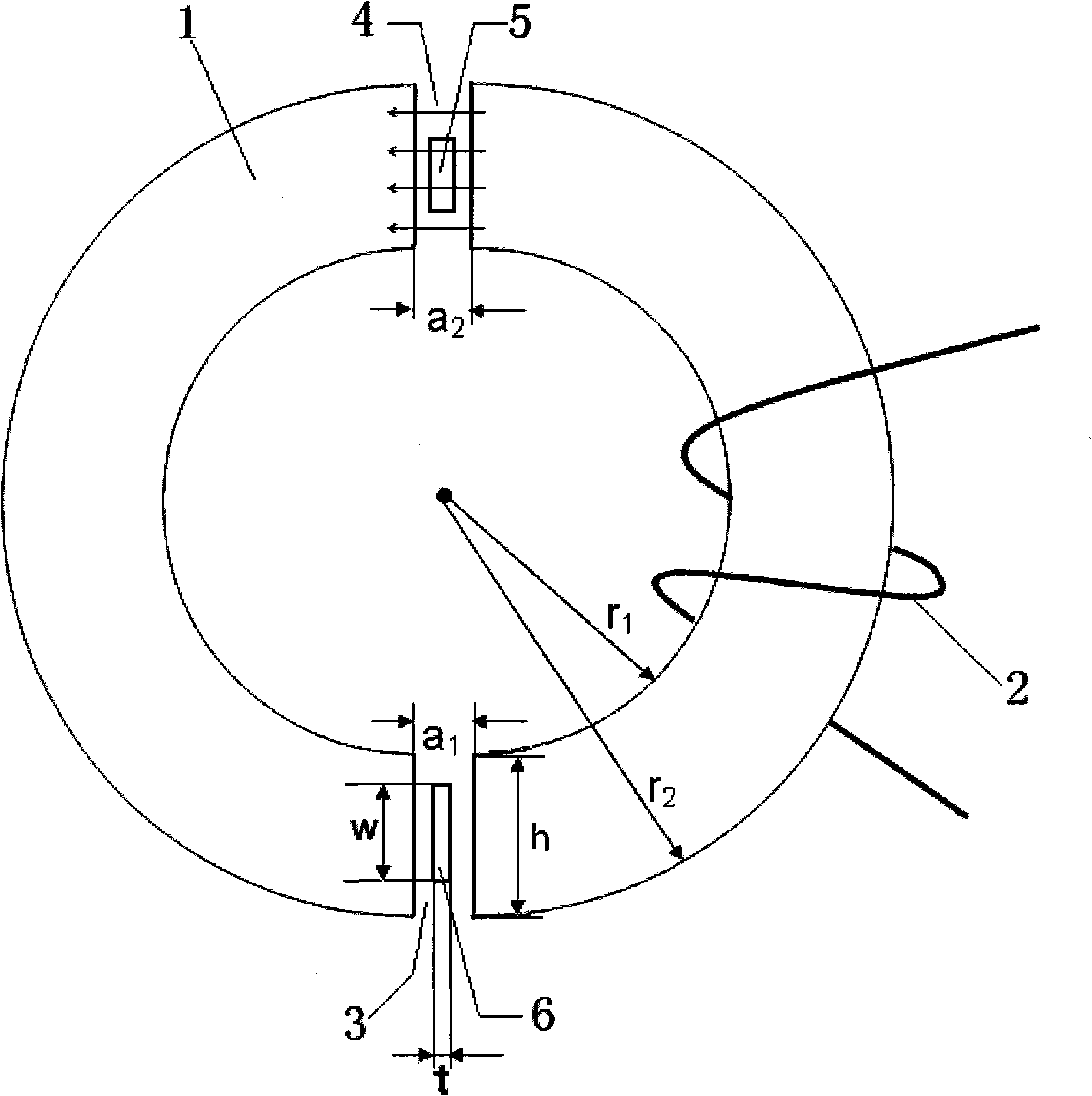

[0026] A schematic diagram of an embodiment of a non-contact superconducting strip current-carrying capacity measuring device is shown in figure 1As shown, the detection magnetic circuit is vertically fixed on the base 10 , and the detection magnetic circuit includes an iron core 1 , an excitation coil 2 , a sample slit 3 and a measurement slit 4 . In order to realize the continuous measurement of the long strip, the first guide wheel 7 and the second guide wheel 8 installed on the base 10 cooperate with the pay-off equipment and the take-up equipment outside the liquid nitrogen container 9 to form a superconducting strip continuous transmission device, The first guide wheel 7 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com