Non-contact type superconduction belt material critical current measuring device

A technology of superconducting tape and critical current, applied in the field of superconducting engineering, can solve the problems of large measurement error, high positioning accuracy, low efficiency, etc., and achieve the effect of reducing the complexity of design and improving the speed of tape running and measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The working principle, measurement process and test results of the non-contact superconducting strip critical current measuring device based on the magnetic circuit method will be described in detail below in conjunction with the accompanying drawings and embodiments.

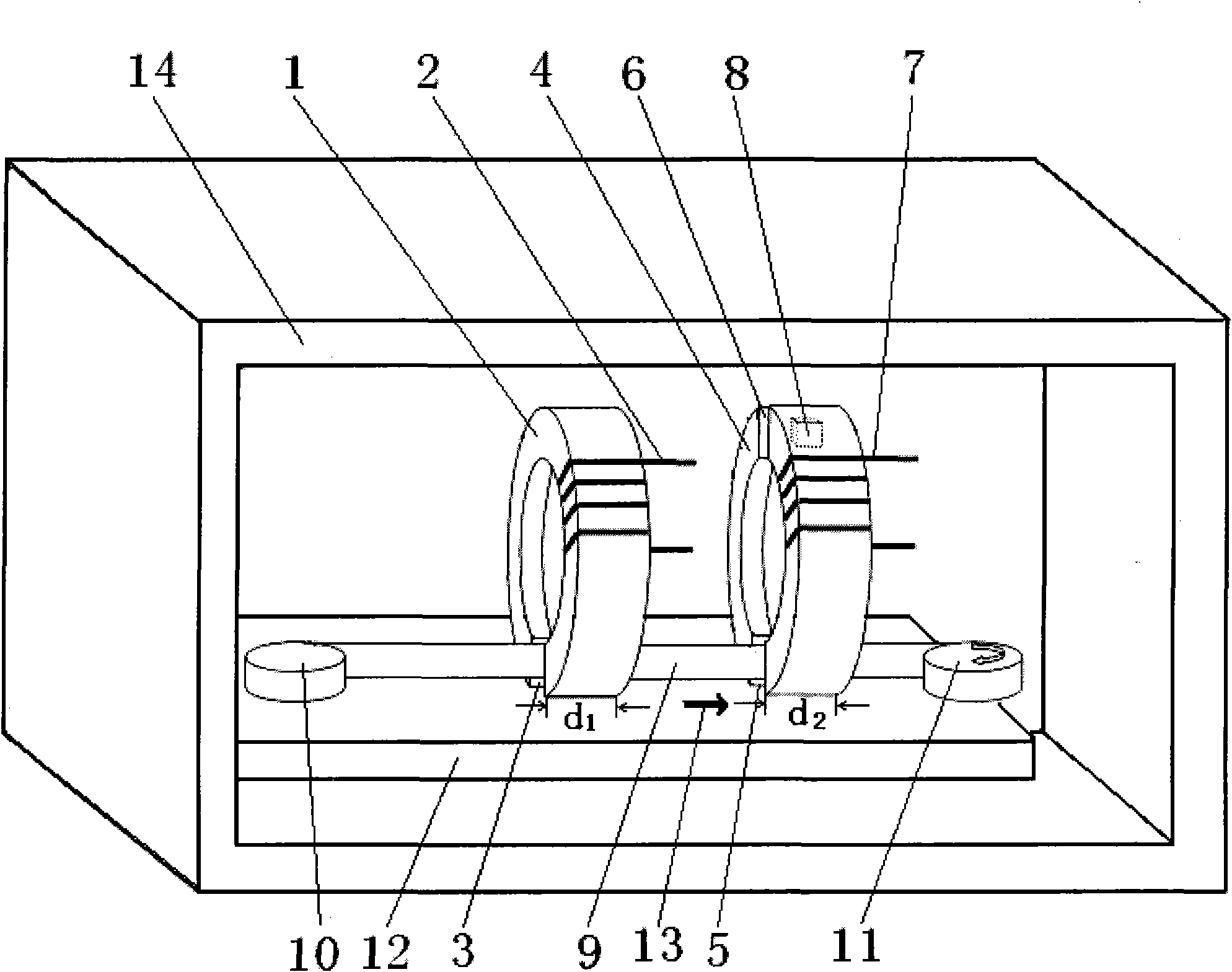

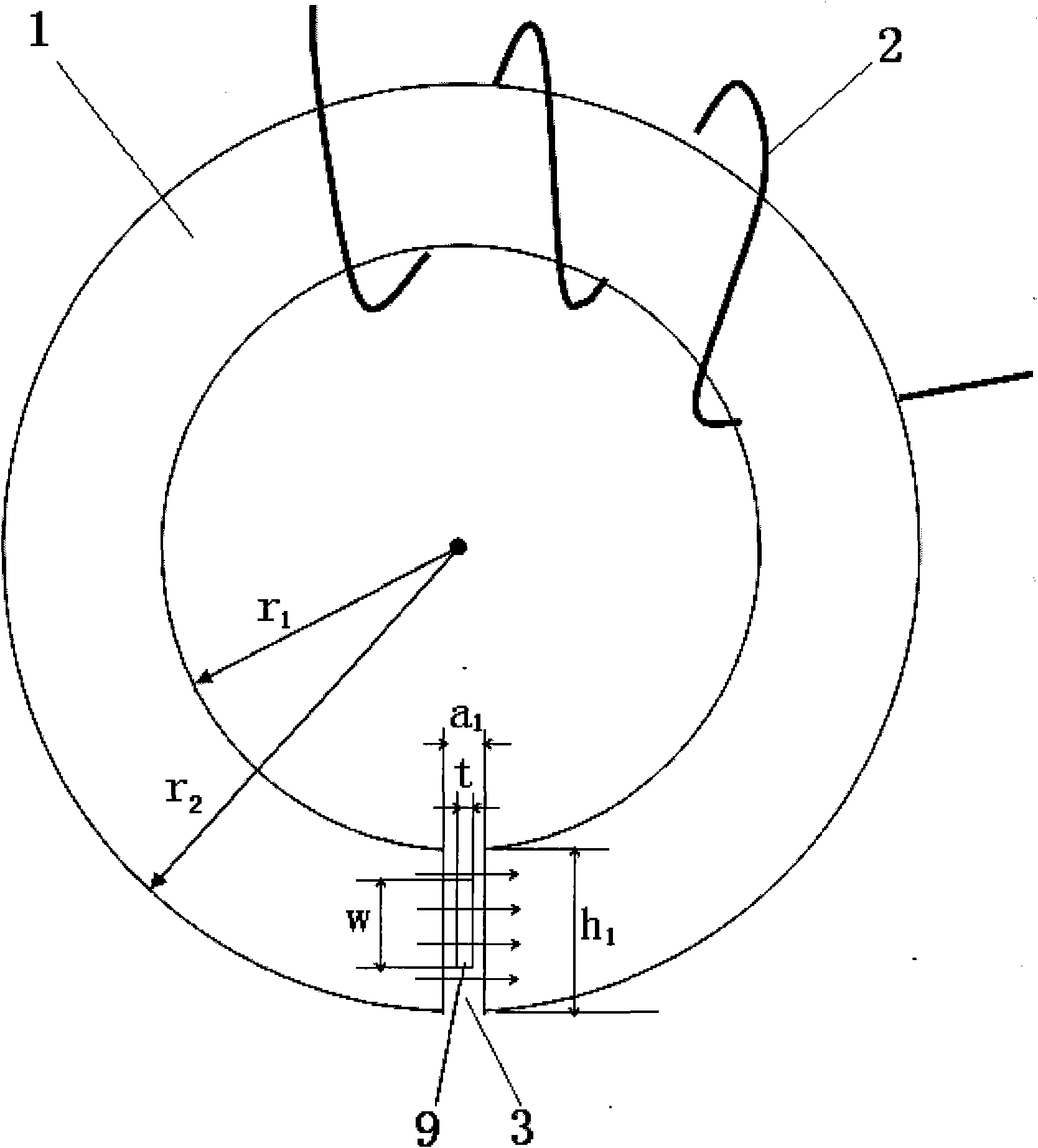

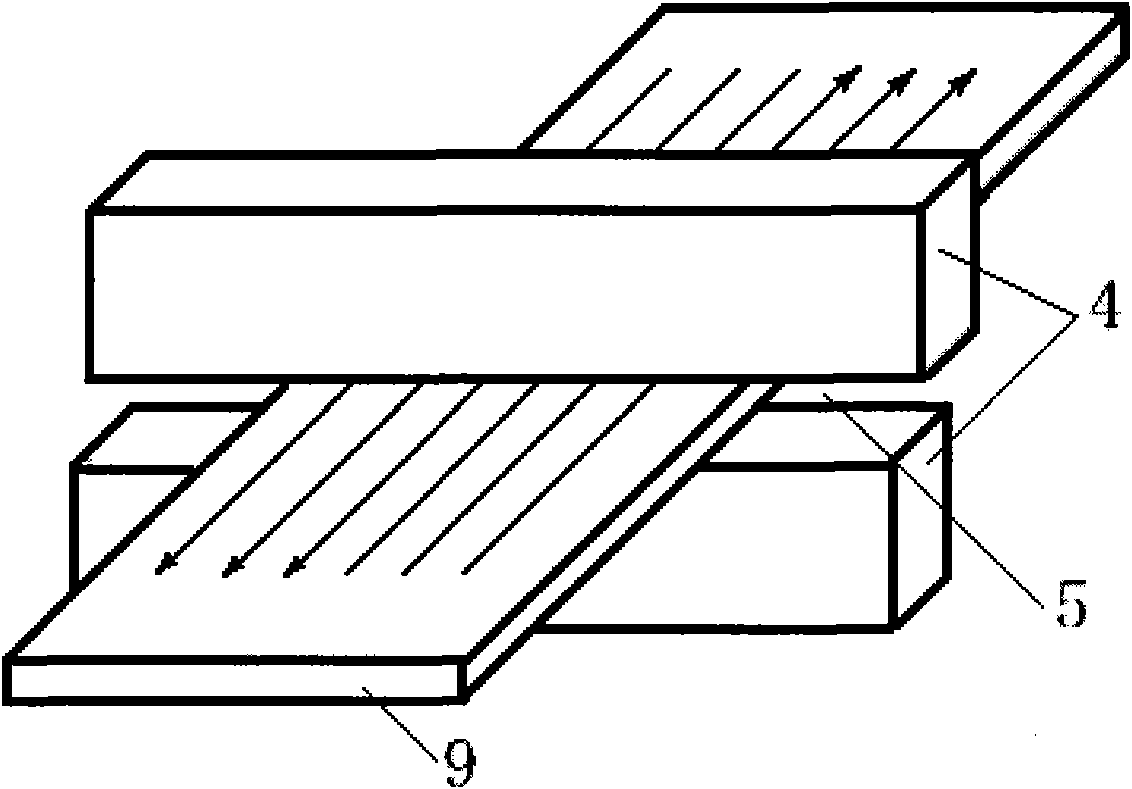

[0028] The schematic diagram of the embodiment of the non-contact superconducting strip critical current measuring device is as figure 1 As shown, the excitation magnetic circuit is on the left, and the detection magnetic circuit is on the right. The height of the central point of the sample slit 5 of the magnetic circuit is the same. In order to realize the continuous measurement of long strips, the first guide wheel 10 and the second guide wheel 11 installed on the base 12 cooperate with the wire-feeding equipment outside the liquid nitrogen container 14 and The take-up equipment constitutes a superconducting strip continuous transmission device, the first guide wheel 10 is on the left side of the exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com