Method and device for testing oxygen permeation of cornea repair material

A technology for repairing materials and testing methods, which is applied in the directions of measuring devices, material separation, and analysis of materials, etc., can solve the problems of single test object of the corneal repair material oxygen permeability testing device, and achieve the effect of low maintenance frequency and lower operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The implementation steps of the testing method of the present invention are:

[0033] (1) Enter the volume V into the gas chromatograph 1 of oxygen, get the peak area S from the spectrum 1 ;

[0034] (2) The two sides of the sample to be tested are respectively passed oxygen and carrier gas, and the oxygen penetrates through the area where the sample is exposed to the oxygen flow to the side of the carrier gas, and the volume V 2 The mixed gas of oxygen and carrier gas is sent to the gas chromatograph, the amount of oxygen in the mixed gas is detected, and the peak area S is obtained from the spectrum. 2 ;

[0035] (3) The oxygen permeability coefficient Dk and oxygen permeability Dk / t of the sample can be calculated by the following formula:

[0036] Dk=(V 1 ×S 2 ×t×Q) / (S 1 ×A×p×V 2 )

[0037] Dk / t=(V 1 ×S 2 ×Q) / (S 1 ×A×p×V 2 )

[0038] Among them, Dk is the oxygen permeability coefficient, the unit is ml cm cm -2 ·s -1 ·Pa -1 ; Dk / t is the oxygen perm...

Embodiment 2

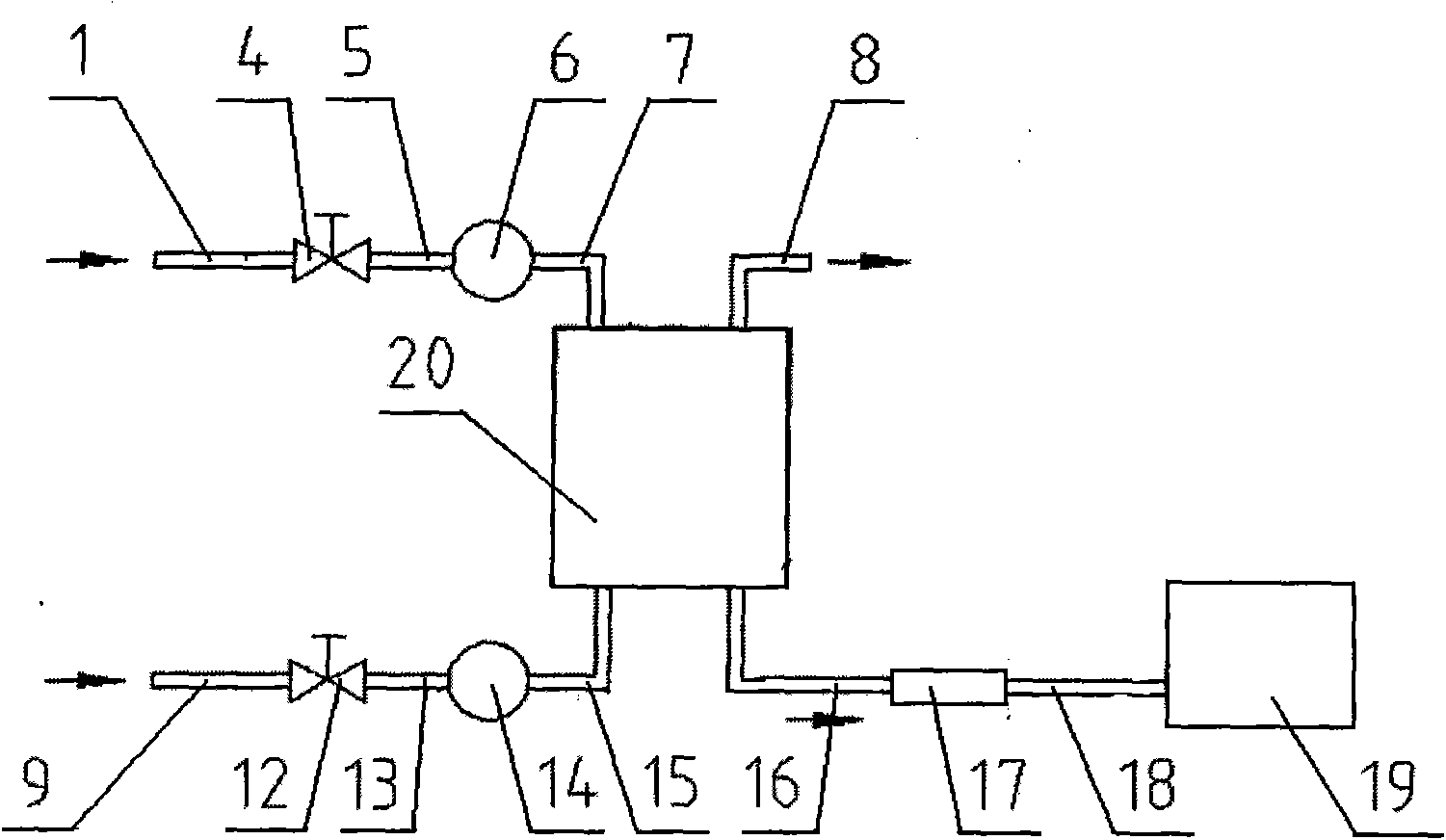

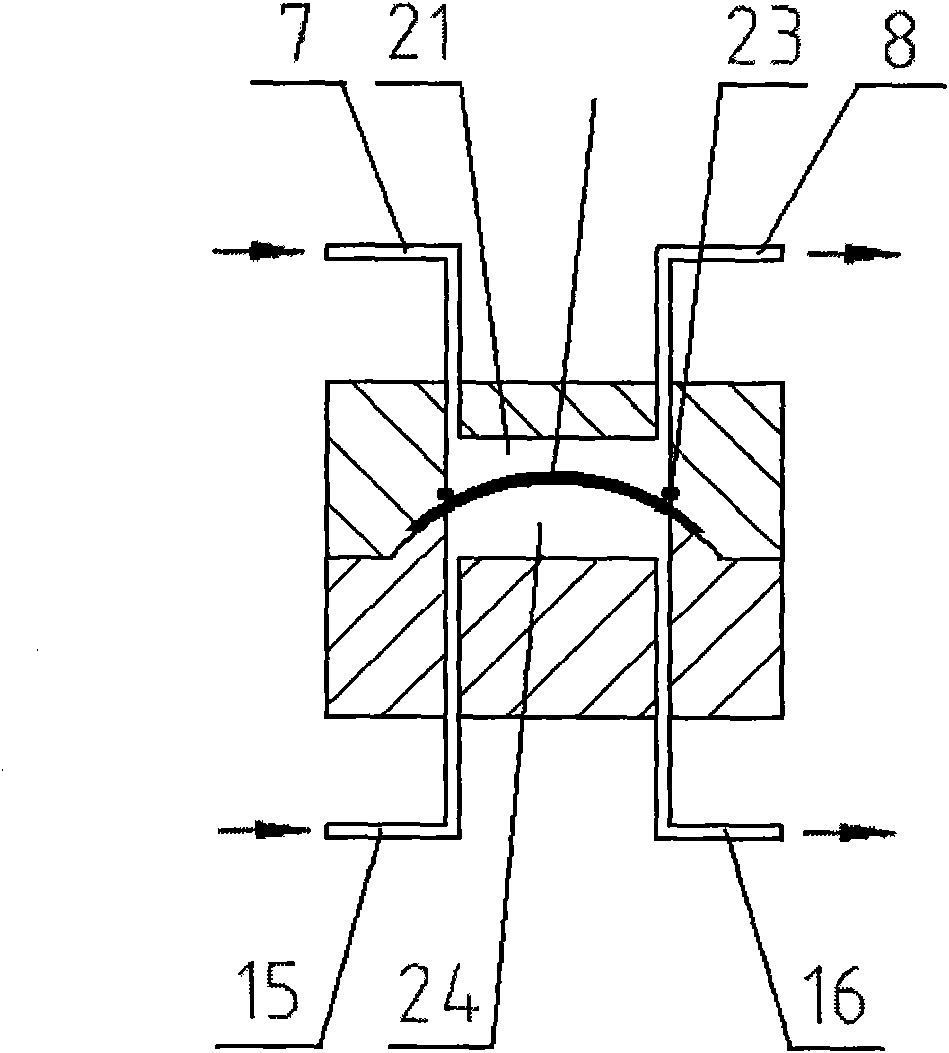

[0041] Such as figure 1 and 2 As shown, the butt joint of the oxygen cavity 21 and the cavity wall of the carrier gas cavity 24 is a matching arc surface, and the sample with a fixed shape is an arc surface. The contact lens oxygen permeability testing device in the present invention mainly includes a sample holder 20, an oxygen inlet Gas device, carrier gas inlet device and detection device, described sample holder 20 is made up of oxygen chamber 21 and carrier gas chamber 24; Oxygen chamber outlet pipeline 8; carrier gas chamber 24 is connected with carrier gas inlet device through carrier gas chamber inlet pipe 15, and is connected with detection device through carrier gas chamber outlet pipe 16; described detection device includes quantitative sampling device 17 and Gas Chromatograph19.

[0042] The oxygen intake device includes an oxygen flowmeter 6, an oxygen pipeline III5, an oxygen flow regulating valve 4, an oxygen pipeline I1 and an oxygen cylinder connected in seq...

Embodiment 3

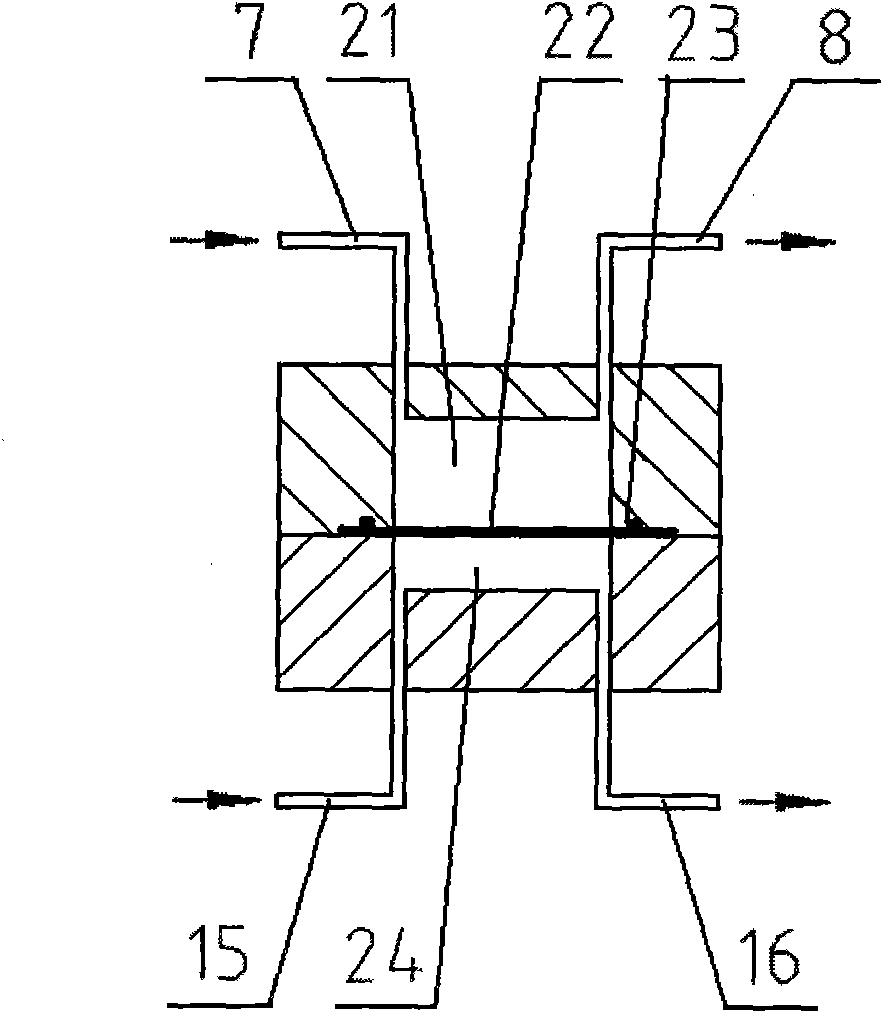

[0052] In the present embodiment, the sample tested is an artificial cornea, using such as image 3 The sample holder, the butt joint of the oxygen chamber 21 and the carrier gas chamber 24 is a plane. The rest are the same as in Embodiment 2 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com