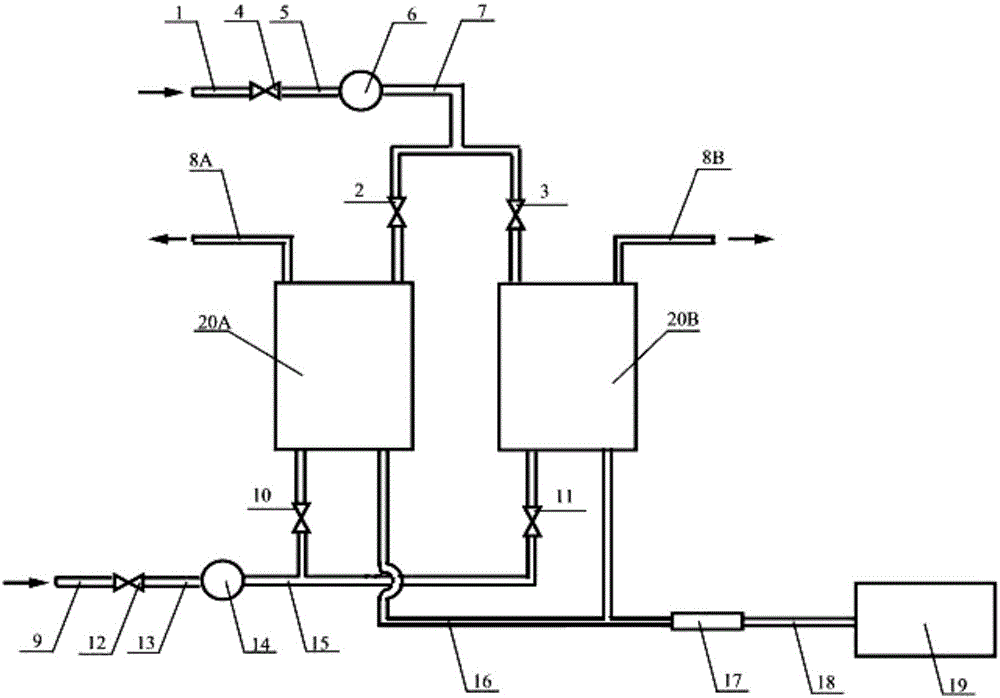

Oxygen permeability test device and oxygen permeability test method

A testing method and testing device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of high price, high operating cost, frequent maintenance and other problems, and achieve the goal of reducing operating costs, reducing system errors, and improving testing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

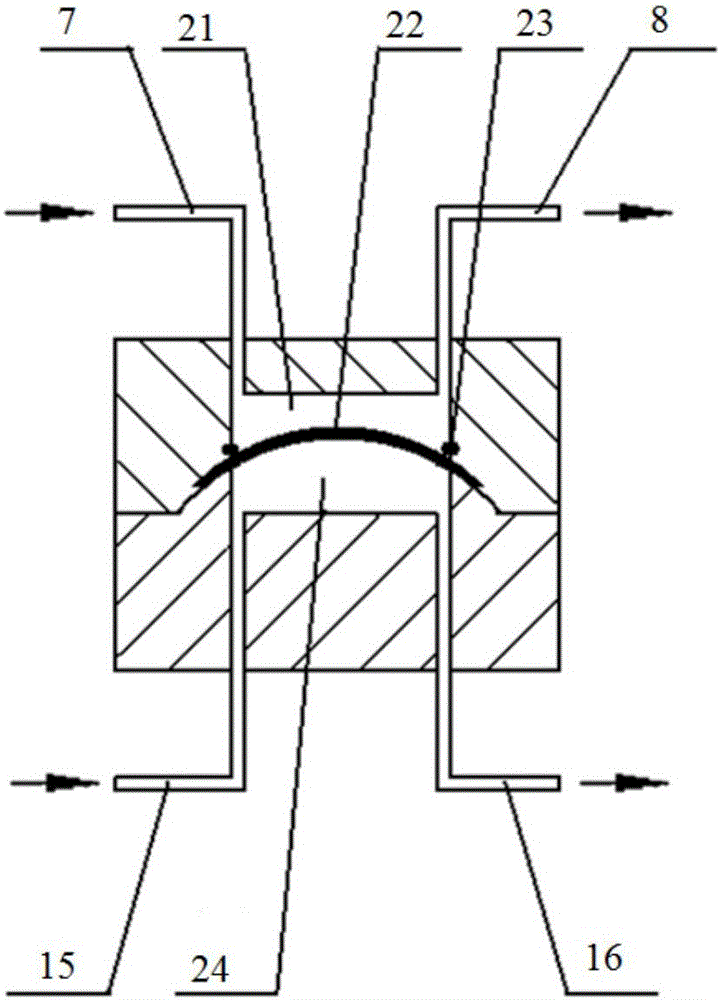

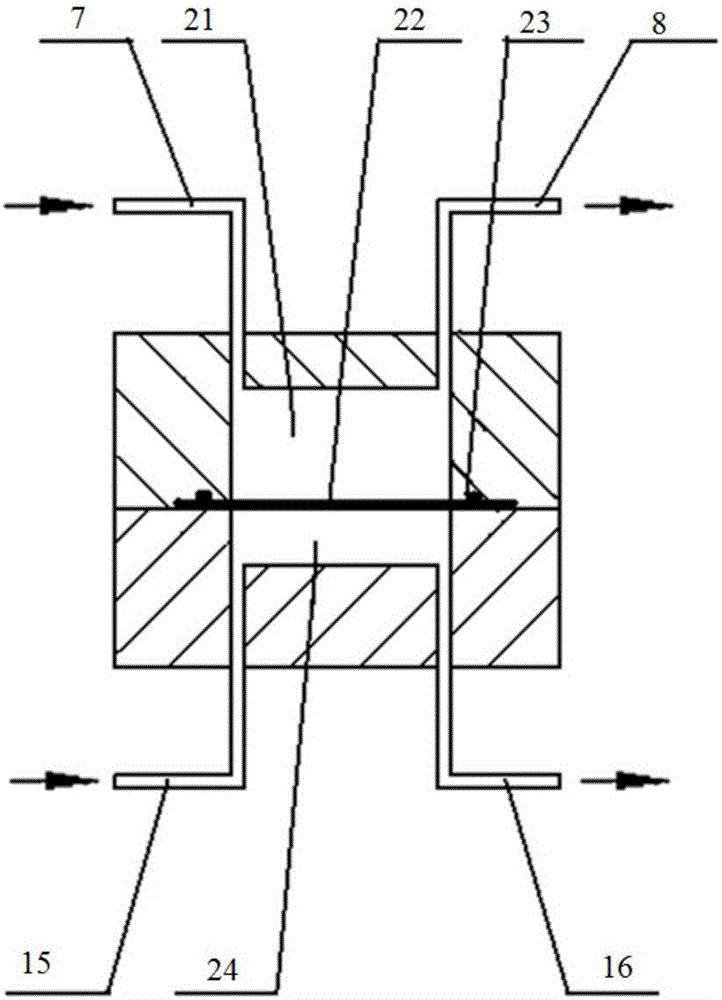

[0053] Test sample: dry chitosan film with fixed arc surface;

[0054] The butt joint between the oxygen chamber 21 and the carrier gas chamber 24 is an arc surface:

[0055] The carrier gas is nitrogen;

[0056] The left and right fixtures were used to test respectively, and compared with the coulometric test results, the test results are shown in Table 1.

Embodiment 2

[0058] Test sample: dry chitosan arc mask with 96.7% degree of deacetylation, the junction of the oxygen chamber 21 and the carrier gas chamber 24 is an arc surface, the carrier gas is nitrogen, and the left and right fixtures are used simultaneously. Channel mode test, and compared with the coulometric test results, the test results are shown in Table 1.

Embodiment 3

[0060] The test sample is a wet chitosan arc mask with a degree of deacetylation of 96.7%;

[0061] The butt joint between the oxygen chamber 21 and the carrier gas chamber 24 is an arc surface;

[0062] The carrier gas is nitrogen;

[0063] The dual-channel mode test using the left and right fixtures at the same time was used, and compared with the test results of the coulometric method, the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com