Multi-connection helical spring

A technology of helical spring and triple helix, applied in the field of spring components, can solve problems such as large volume, influence on muscle use, harmful internal force or macroscopic torsion, etc., and achieve the effect of good structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

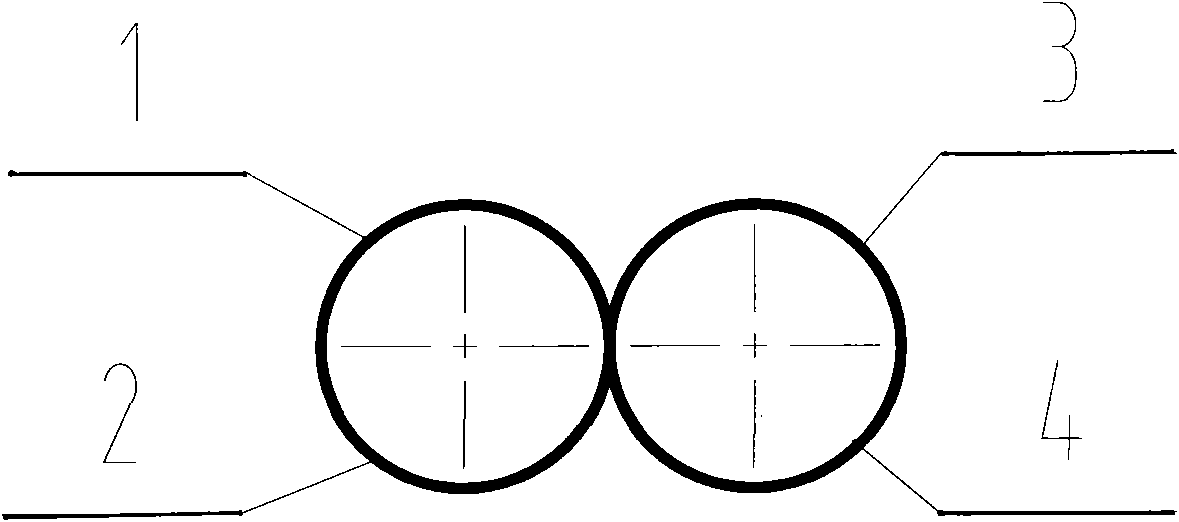

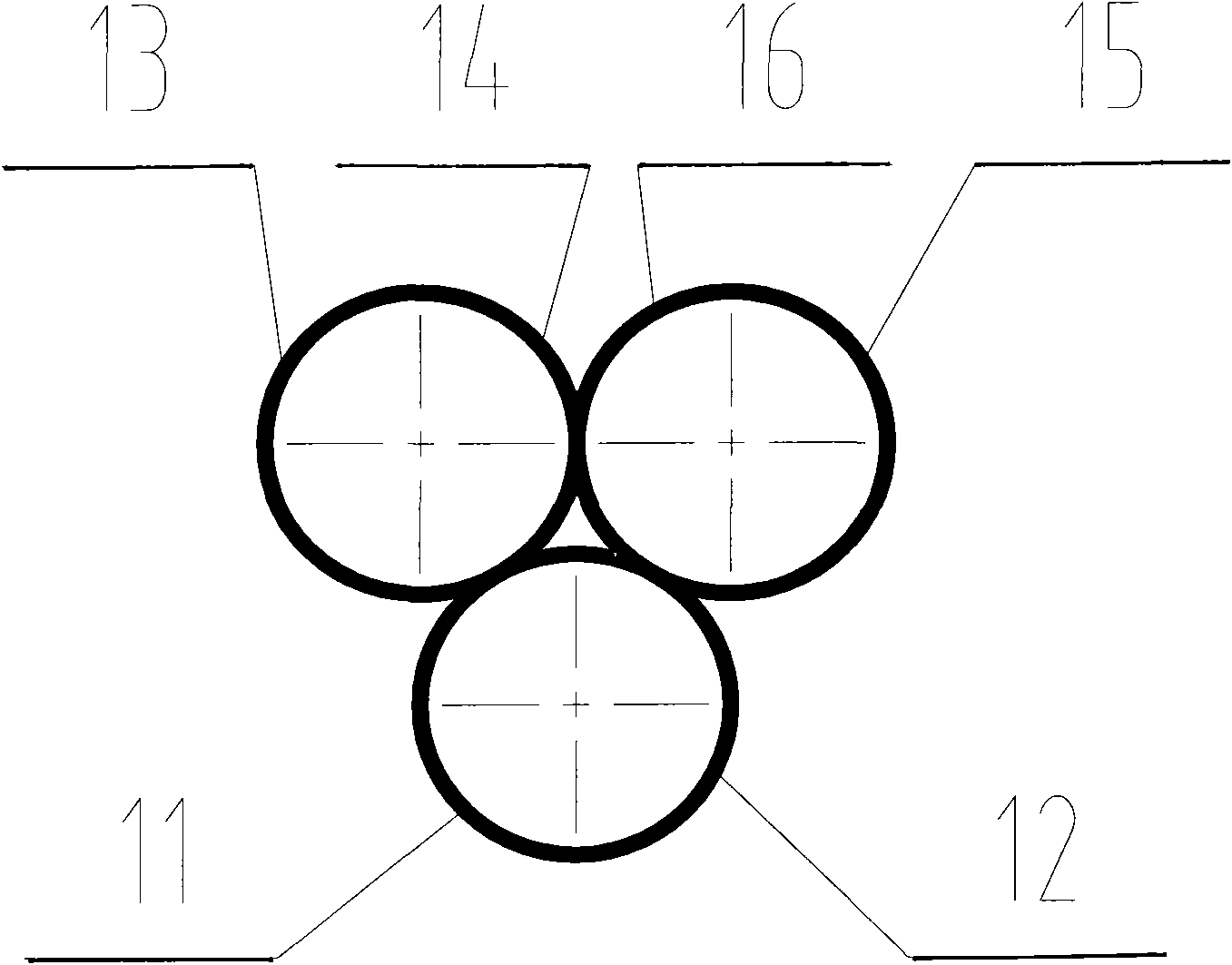

[0015] The coil spring widely used at present is a single helical structure, and the cross section is a single ring. The present invention is made of a spring wire, multi-connected and multi-axial columnar springs, and the cross-section is a multi-ring structure.

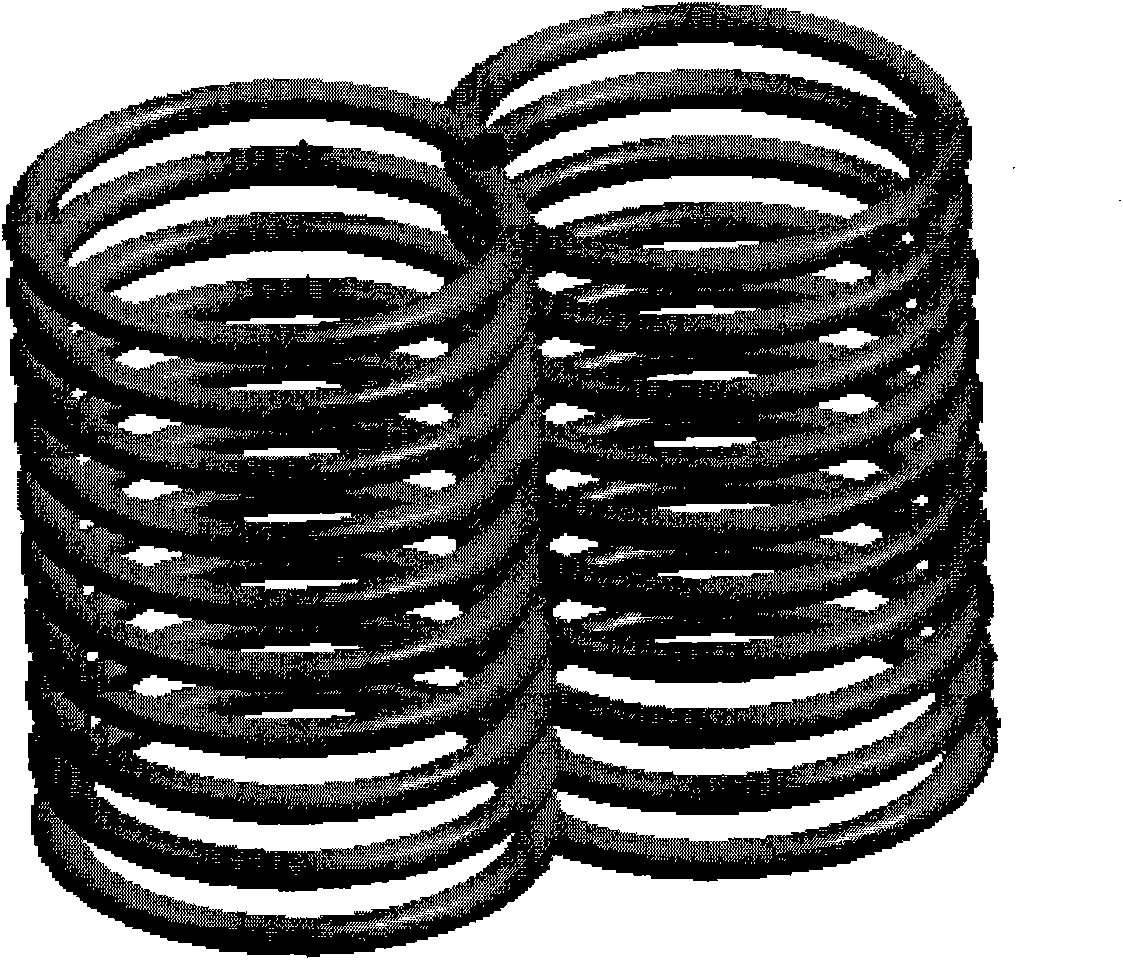

[0016] As shown in the figure, a multi-connected helical spring is provided with a spring wire. The spring is in a multi-layer state. The three-dimensional shape is like a plurality of columns connected together, and the cross-section is like a plurality of rings connected into one body; among them, the double-connected helical spring, Section A of each layer is arc-shaped, bends counterclockwise along the helix direction, and enters Section B 2; The spring wire of section 3 bends upward clockwise in an arc along the direction of the same helix angle, and enters section 4; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com