Downhole cooling air-cooling dehumidifier

A dehumidifier and air-cooling technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of small fluid resistance, low heat transfer coefficient, large resistance of cooling dehumidifier, etc. The difference in thermal coefficient, increase the heat transfer area, and increase the effect of liquid side heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

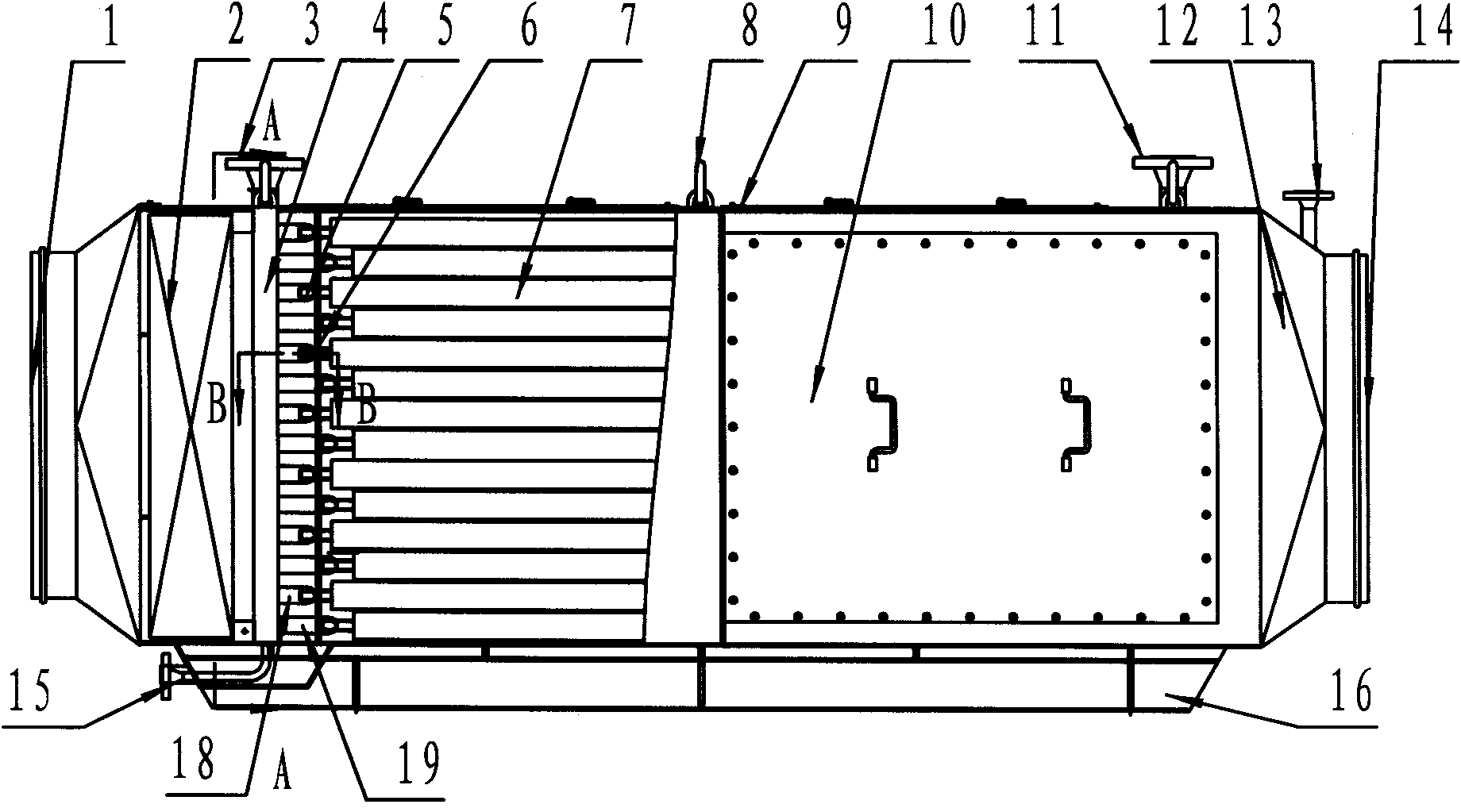

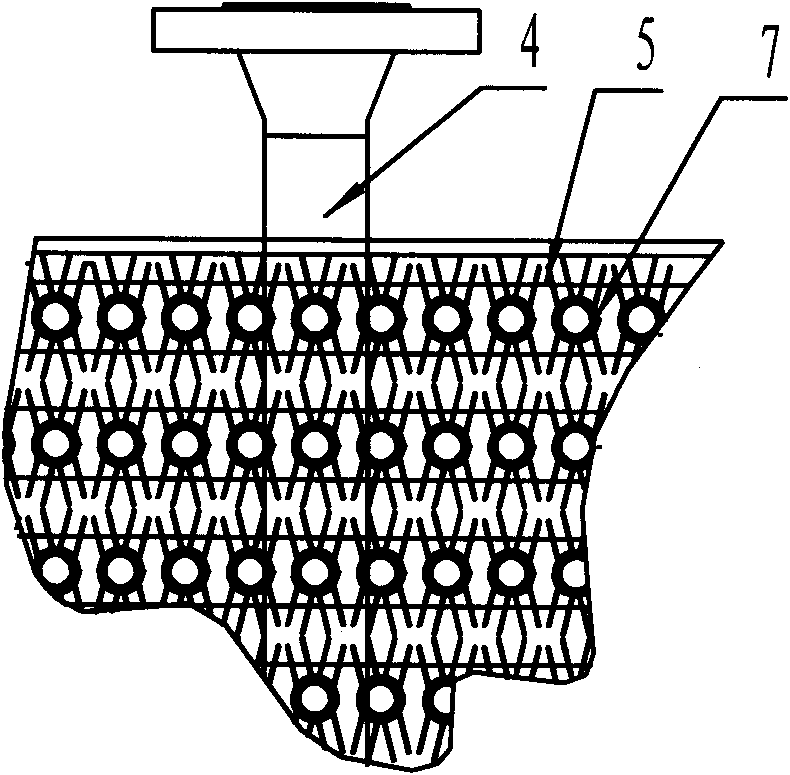

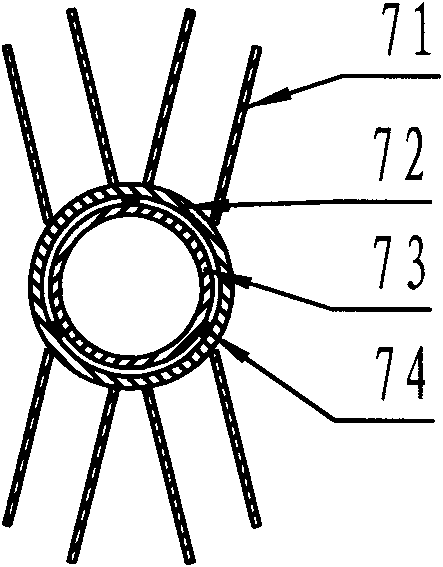

[0019] Embodiment 1, an air-cooled dehumidifier for downhole cooling, including a shell, a heat exchange tube unit 7, a header tube 5, a liquid inlet pipe 4, and a liquid outlet pipe, characterized in that: the heat exchange tube unit is from inside to outside These are the inner tube 73, the outer tube 72, and the fins 71 in sequence. There is a long support bar 74 between the inner tube and the outer tube. The outer tube and the inner tube are gas channels, and the inner tube and the outer tube are liquid flow channels. , each heat exchange tube unit is arranged in a rectangular array, the heat exchange tube unit vertically intersects with the horizontal header tube, the inner tube passes through the header tube, the header tube communicates with the heat exchange tube liquid channel, and the header tube and The liquid inlet and outlet pipes are vertically connected through connecting pipes, and each row of heat exchange tube units is equipped with a support frame 6 . Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com