Mounting construction method of liner plates during mounting large-scale precision equipment

A technology of precision equipment and construction methods, applied in infrastructure engineering, construction, etc., can solve the problems of not ensuring good contact between the backing plate and the equipment, not ensuring good contact between the backing plate and the equipment, spending a lot of time and labor material costs, etc. Achieve the effect of saving labor costs, optimizing construction procedures, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

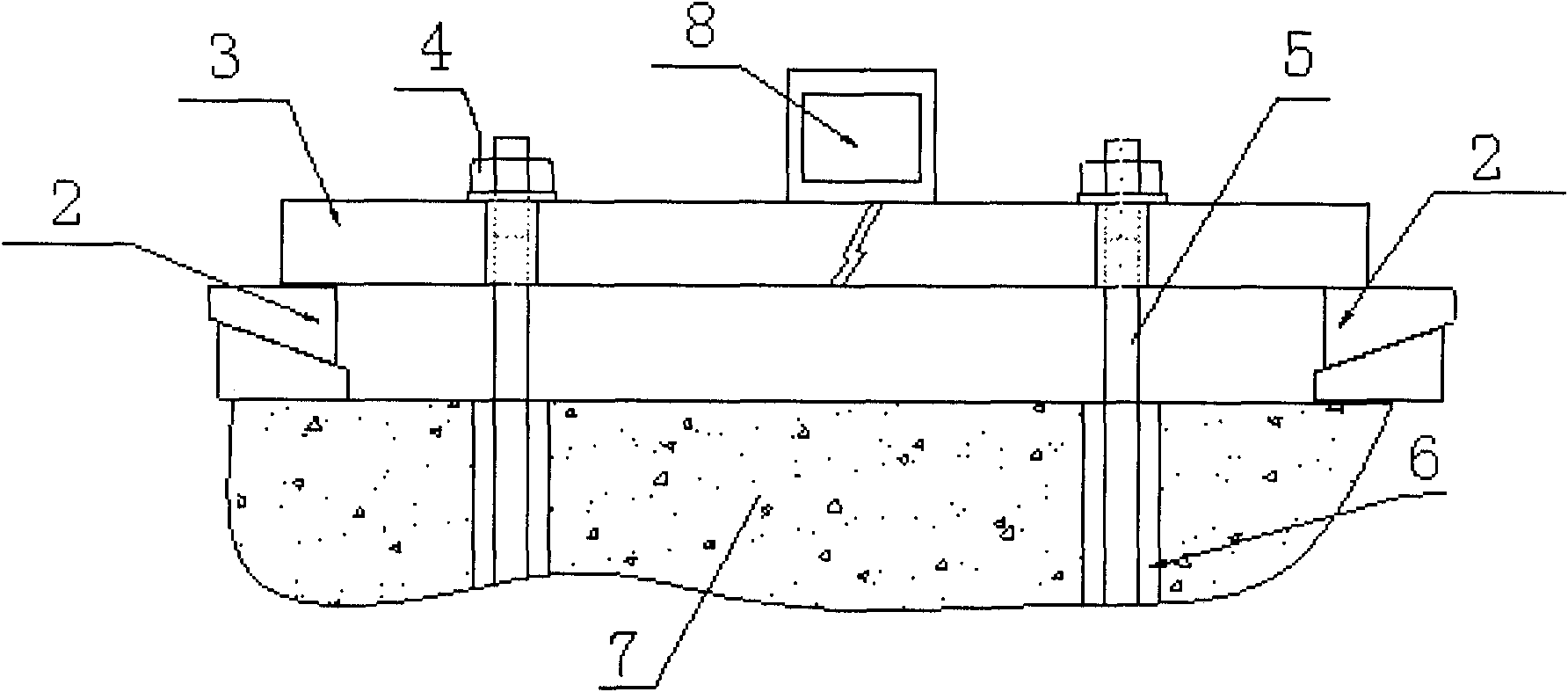

[0044] The installation and construction method of backing plate in the installation of large precision equipment of the present invention, the steps are as follows:

[0045] Preparations include:

[0046] 1) According to the weight of the equipment, prepare a temporary backing plate, and it is advisable to choose an inclined iron;

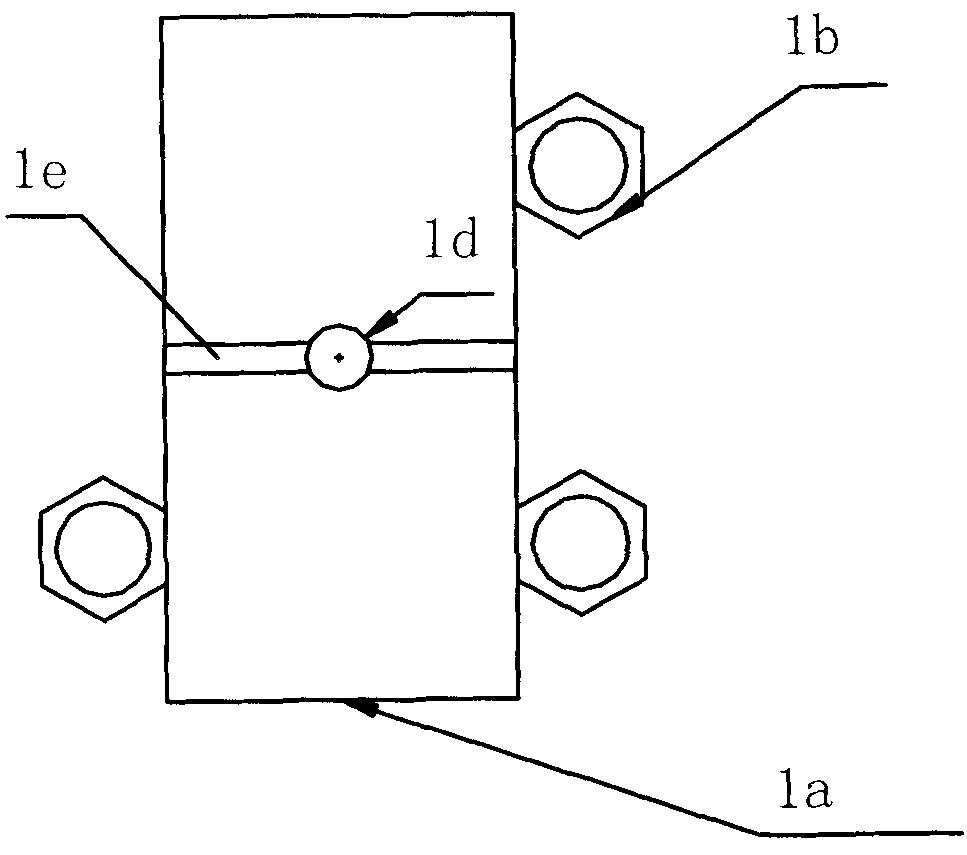

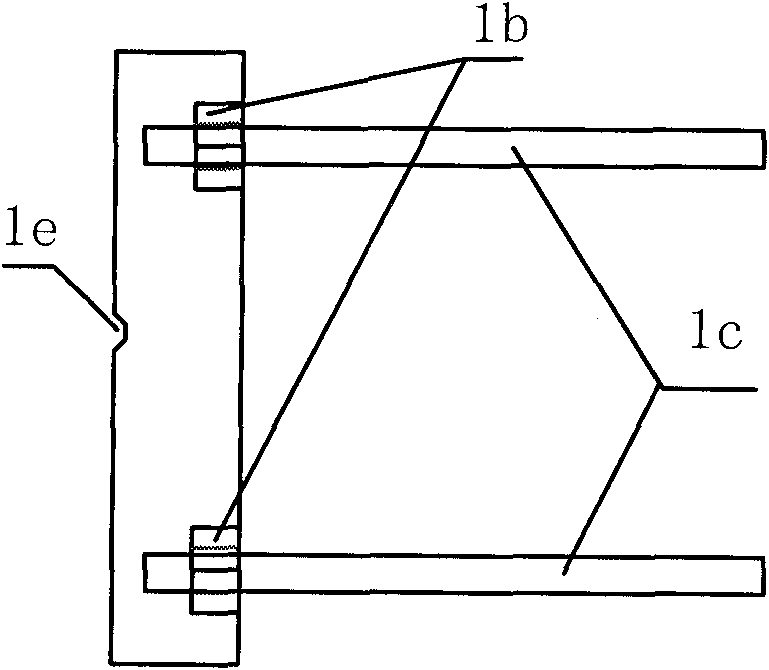

[0047] 2) if figure 1 , figure 2 : The backing plate is designed according to the weight of the equipment, the pre-tightening force of the anchor bolts and the strength of the foundation concrete. The backing plate 1 includes a horizontal plate body 1a, and 3 to 4 backing plate nuts 1b are welded on the long side of the backing plate, which match the backing plate nuts. Backing plate support bolt 1c, with exhaust hole 1d and exhaust groove 1e in the middle of the backing plate; generally, three nuts are welded on the long side of the backing plate, and the welding position should be considered to be easy to operate, and one nut is welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com