Multipoint synchronous push construction method for porous large-span continuous steel truss girder

A technology of jacking construction and steel truss girders, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve the problems of difficult to ensure the quality of steel truss girder erection, the force of the slideway should not be too large, and the span of jacking can not be too large and other problems to achieve the effect of avoiding assembly operations, reducing labor intensity of workers, and improving assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

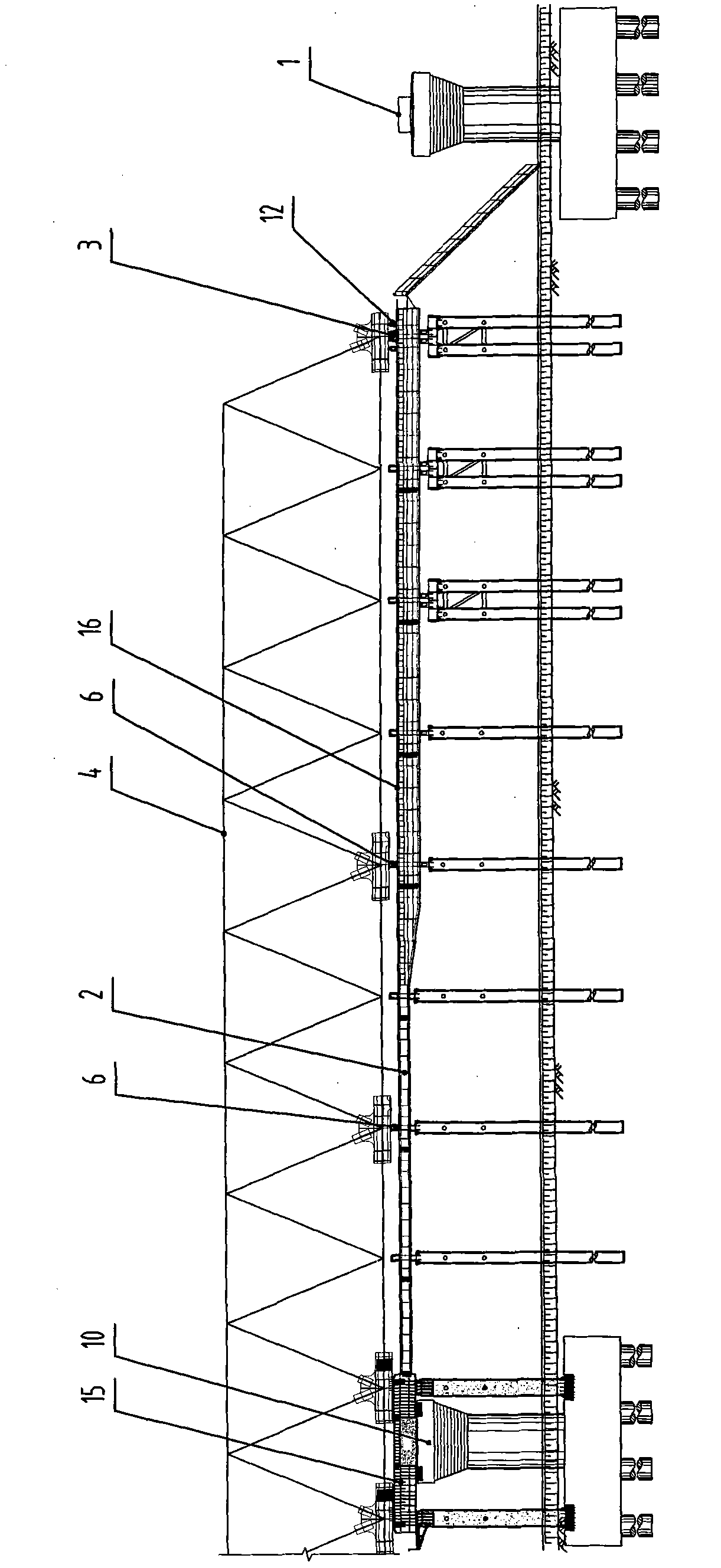

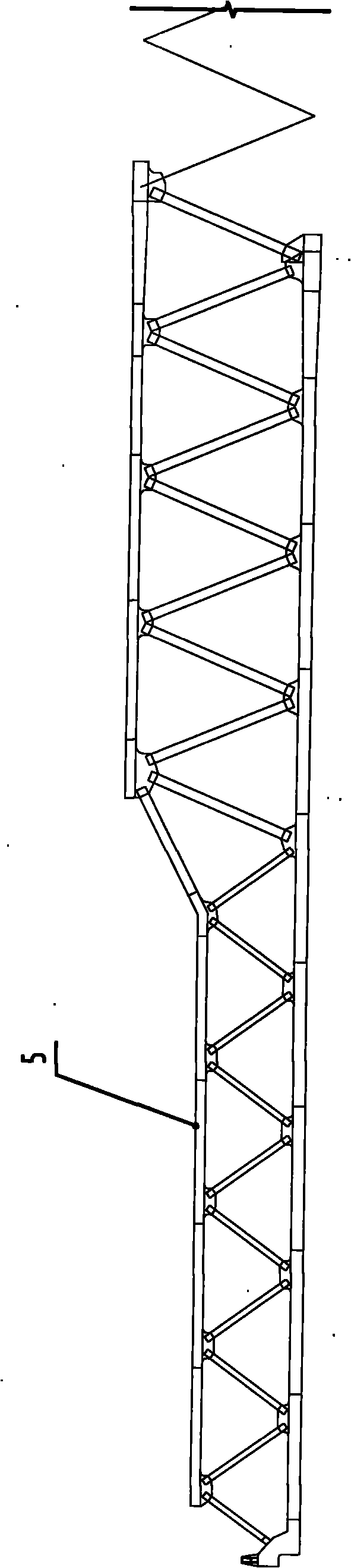

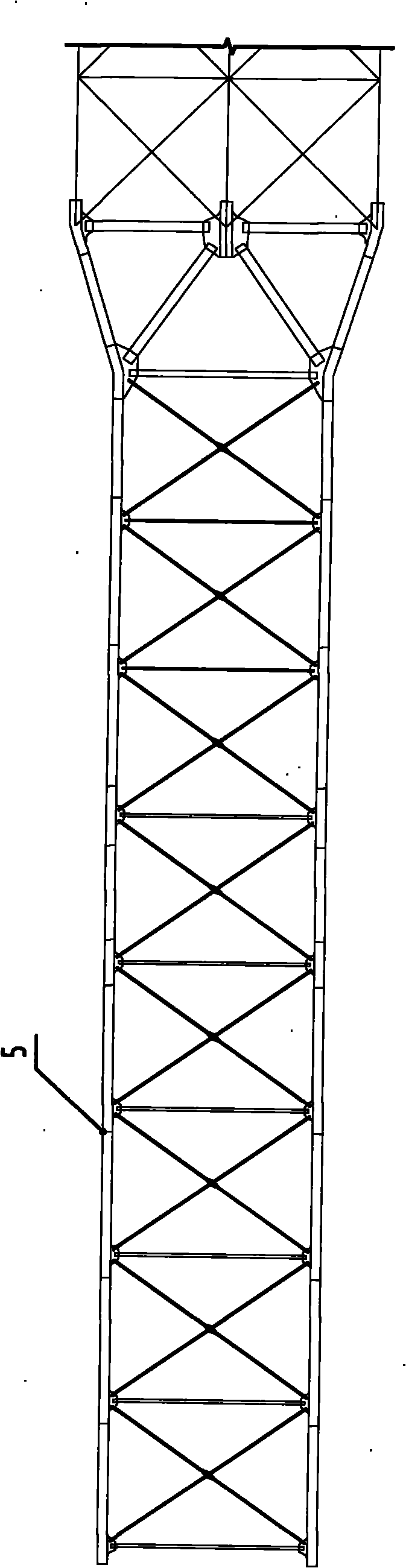

[0042] Such as Figure 1 to Figure 14 As shown, the porous large-span continuous steel truss girder multi-point synchronous jacking construction method of the present invention comprises the following steps:

[0043](1), assemble the steel truss girder assembly platform 2 between the bridge pier 1 and the bridge pier 10 on the bank, according to the weight, span, internode length, width of the steel truss girder 4 and the bearing capacity of each internode on the steel truss girder assembly platform 2 Force situation design steel truss girder assembly platform 2, slideway, slide block, the slide block is set on the steel truss girder assembly platform 2, and the upper surface of the steel truss girder assembly platform 2 serves as a pushing slideway at the same time. Steel truss girder assembly platform 2 is the assembly site for all steel truss girders 4, and is arranged at one end of the pushing starting point. Its length can be selected according to the comprehensive consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com