Non-woven fabric forming equipment

A forming equipment and web-forming technology, which is applied in the direction of non-woven fabrics, filament/thread forming, textiles and papermaking, etc., can solve the problems of spinning breakage, uneven cloth thickness, and low strength of non-woven fabrics, and achieve uniform and stable airflow , It is not easy to break when spinning, and the effect of high weaving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

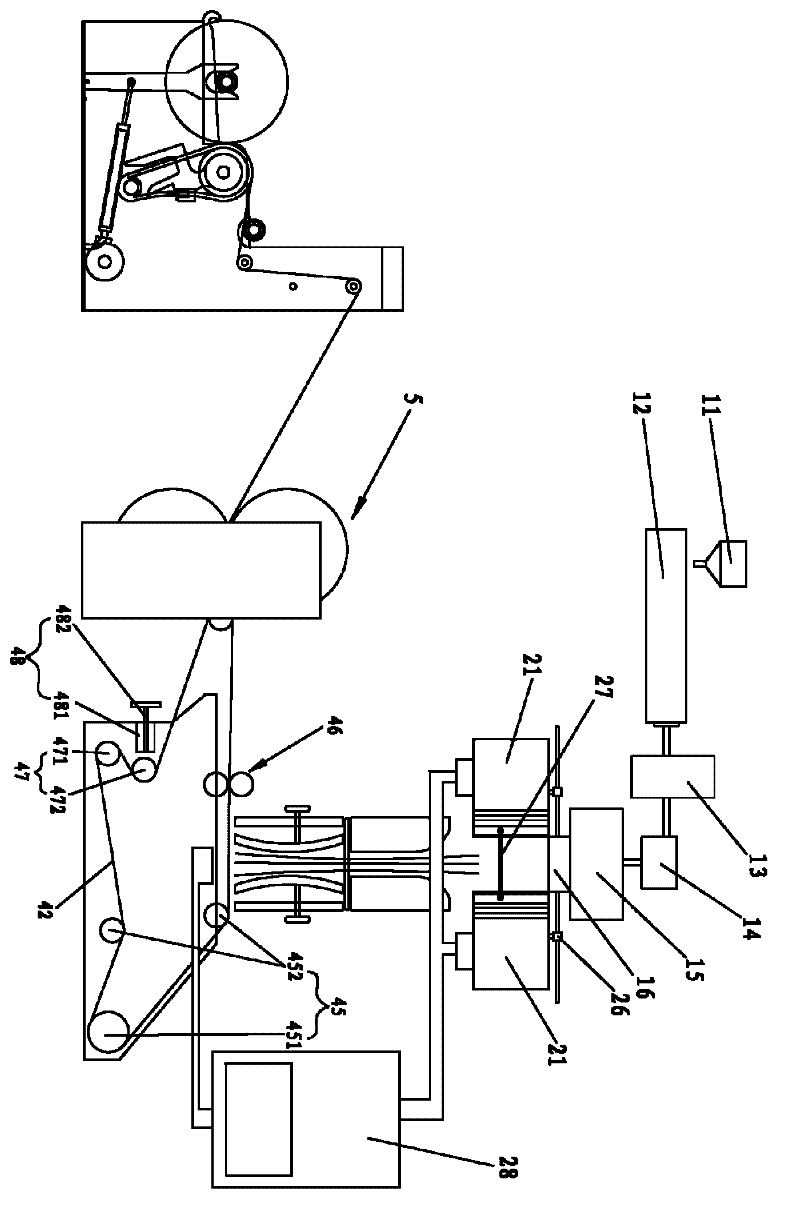

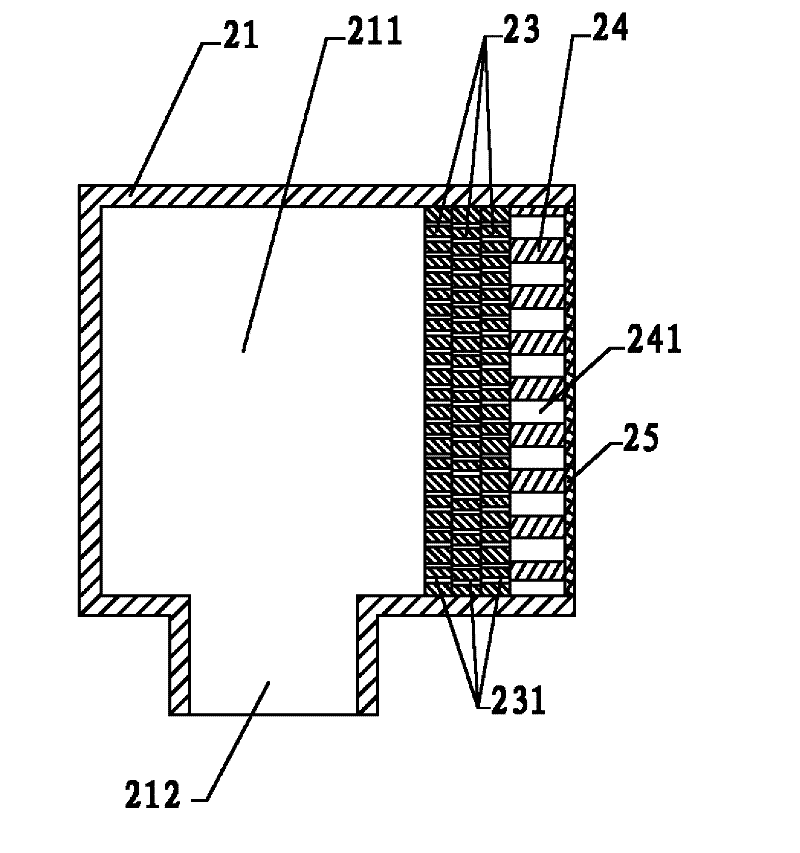

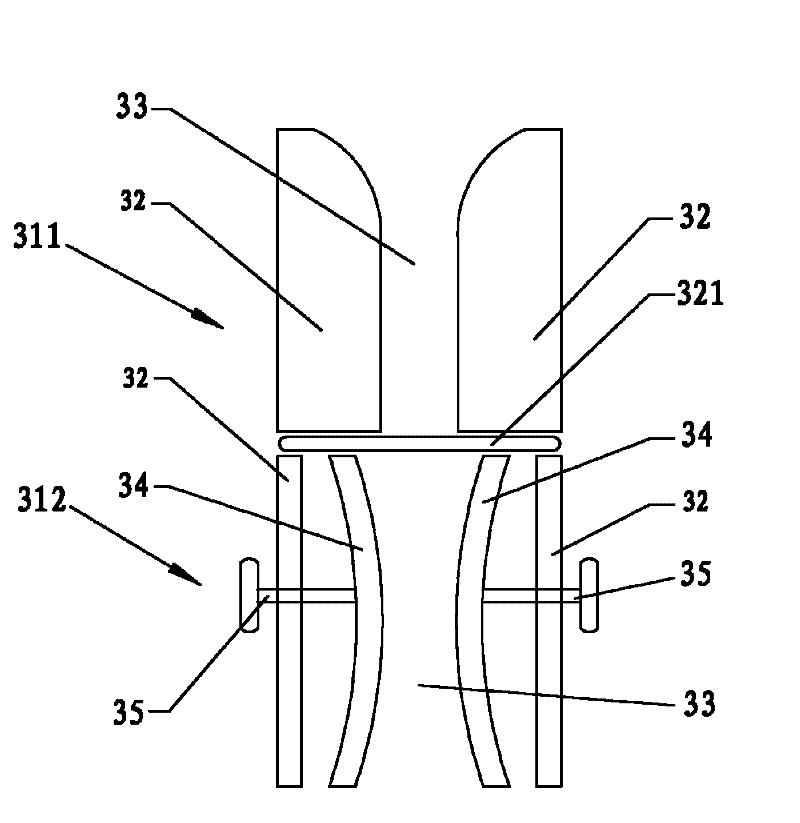

[0060] See Figure 1 ~ Figure 4 As shown, a kind of non-woven fabric forming equipment in this embodiment includes an extruding device, a spinning box 15 provided with a nozzle 16, a cold air supply device, a traction stretching device, a web forming device, and a hot rolling device 5 in sequence according to the material conveying direction. and winding device; the cold wind supply device includes a compressed air generating device 28 and a cold air box device, and the cold air box device includes a pair of boxes 21 which are respectively located on both sides below the nozzle 16, and each box body 21 is inside An air flow channel 211 is formed, and the box body 21 is provided with an air inlet 212 connected to the compressed air generating device 28. The air outlet of the box body 21 is directly below the nozzle 16, and the air flow channel 211 is close to the air outlet. An airflow deceleration plate 23 is provided, and the airflow deceleration plate 23 is provided with a h...

Embodiment 2

[0086] The winding device of this embodiment is different from that of Embodiment 1.

[0087] See Figure 8 ~ Figure 11 As shown, the rewinding device in this embodiment includes a rewinding frame 71, the rewinding frame 71 is provided with a conveying roller 72 and a rewinding roller set 73, and the rewinding frame 71 is pivotally provided with a knife holder 74 , the rear end of the knife holder 74 is pivotally connected to the winding frame 71 through a pivot parallel to the winding roller set 73 , and a pair of cutting knives 75 perpendicular to the winding roller set 73 are arranged at the front end.

[0088] Wherein, the number of the transmission rollers 72 is at least two; the winding roller set 73 includes a front winding roller 731 and a rear winding roller 732 which are parallel to each other and positively rotate in opposite directions. During the winding process, the formed non-woven fabric webs are staggered around the conveying roller 72 in turn, then staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com