A dyeing machine cloth lifting device with adjustable traction

A dyeing machine and traction technology, applied in the direction of processing textile material drums, textile material carriers, etc., can solve the problems of reducing the dyeing efficiency of fabrics, insufficient traction, slippage of cloth lifting rollers and fabrics, etc., to improve dyeing efficiency and easy adjustment. Effect

Active Publication Date: 2022-06-03

ZHEJIANG TWIN LANTERN HOME TEXTILE

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traction force of the existing cloth lifting device for cloth dyeing is often insufficient, resulting in slippage between the cloth lifting roller and the fabric, thereby reducing the dyeing efficiency of the fabric

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

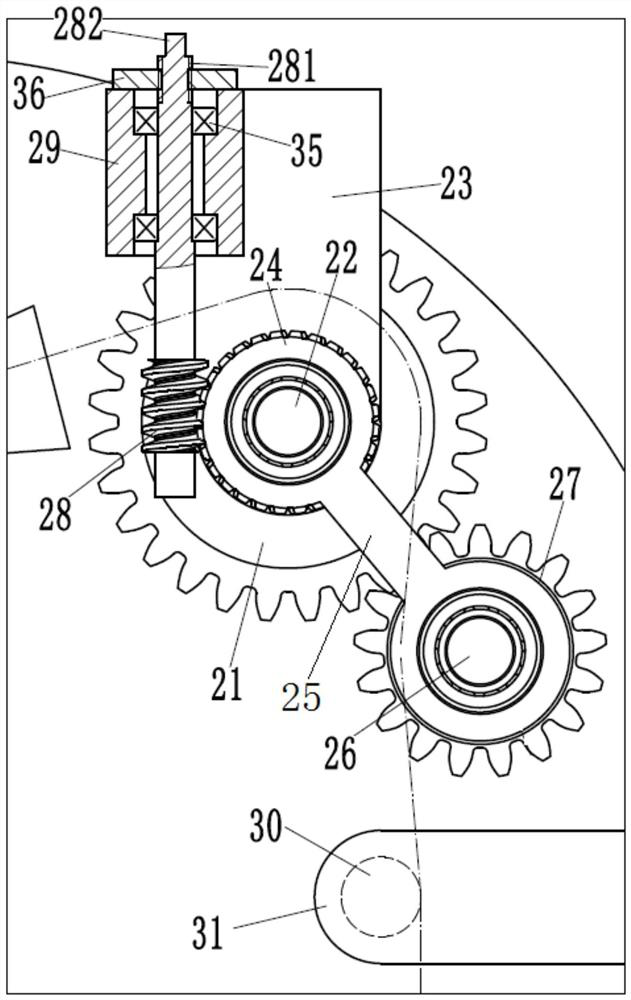

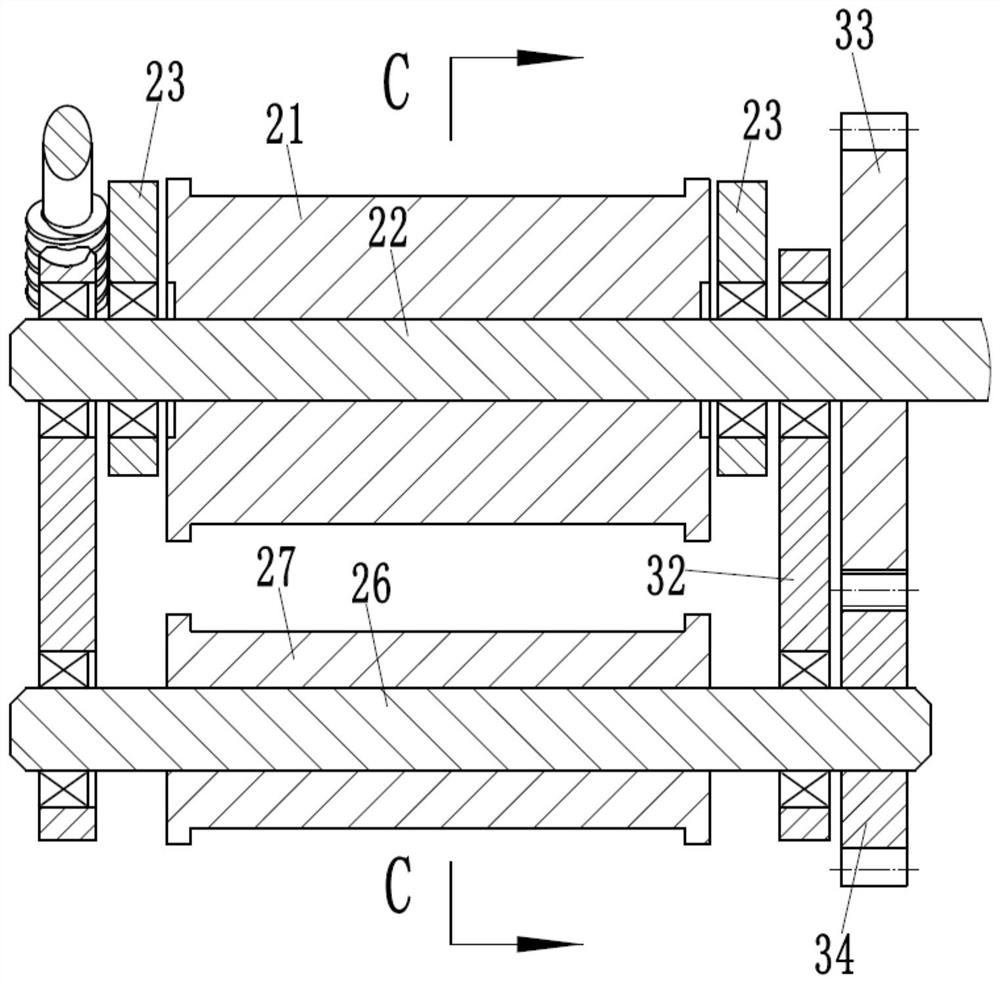

[0024] Further, the rightmost end of the right side wall of the limit roller 30 and the rightmost end of the right side wall of the cloth lifting roller 21 fall down

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

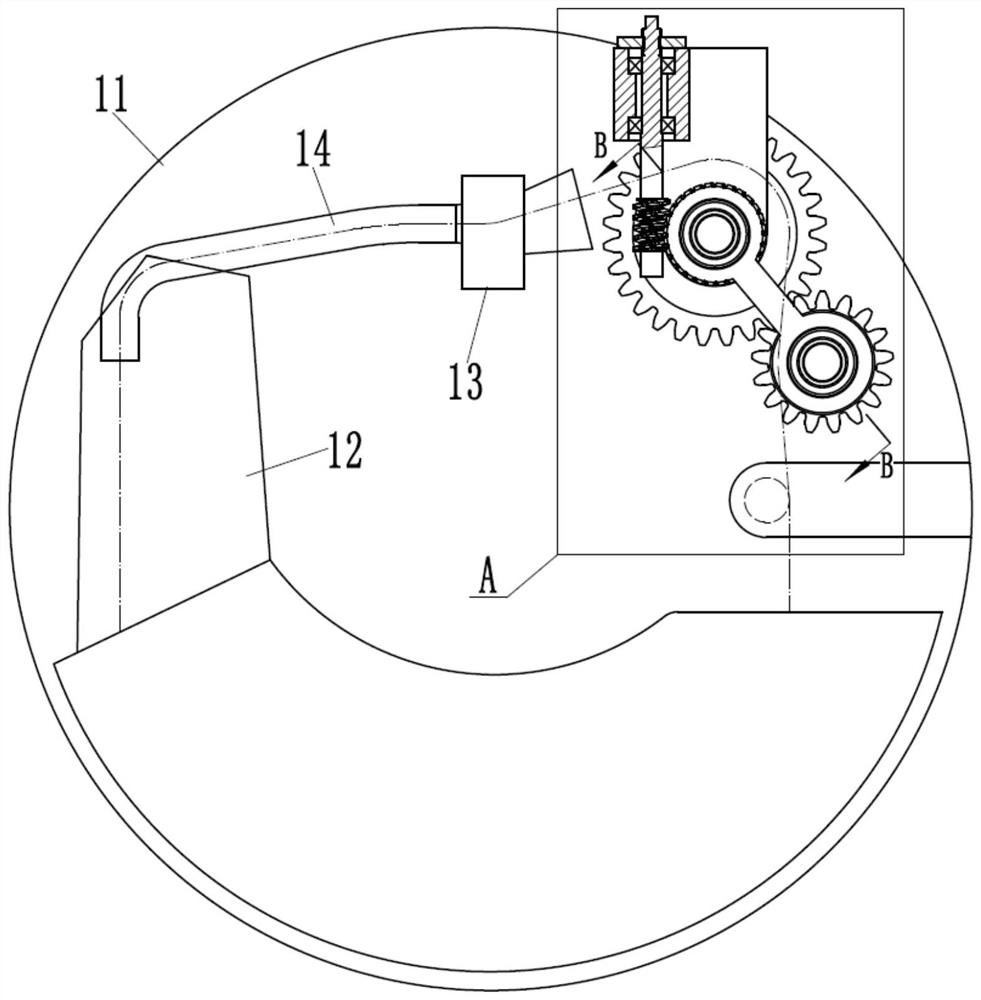

The invention discloses a dyeing machine cloth lifting device with adjustable traction force, which comprises a cylinder body of the dyeing machine and a cloth lifting device. In the middle of the shaft, the support shaft is hinged on the connection plate, which is fixedly connected with the cylinder body. A worm wheel is hinged on the support shaft. An articulated arm is fixed on the outer wall of the worm wheel. An adjustment shaft is articulated on the lower end of the articulated arm. Regulating roller; the worm gear is meshed with a worm, the upper end of the worm protrudes out of the end cylinder, and a limit roller is arranged below the regulating roller, which is fixed on the inner wall of the cylinder through a support plate. The invention changes the wrapping angle of the fabric to the fabric lifting roller by changing the position between the adjustment rollers, thereby changing the traction force of the fabric lifting roller to the fabric, and the adjustment method is simple and fast, and can be applied to different fabrics at the same time, which can effectively improve the dyeing efficiency.

Description

A cloth lifting device for dyeing machine with adjustable traction force technical field The present invention relates to the technical field of textile dyeing and finishing machinery, in particular to a dyeing machine with adjustable traction set. Background technique [0002] The dyeing machine is used for processes such as dyeing, bleaching, scouring and washing of ready-made garments such as wool sweaters, acrylics and cotton sweaters. It is an ideal bleaching and dyeing equipment suitable for a wide range of finished products for the bleaching and dyeing of gloves, socks, towels and other finished products. In the continuous production of textile finishing, because the textile fabric is passively unrolled, it needs to be carried out under the traction of the cloth lifting device. When unwinding and continuous production, high-speed cloth pulling is required. However, the traction force of the existing cloth dyeing cloth lifting device is often If it is not enou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06B23/02D06B23/04

CPCD06B23/02D06B23/04

Inventor 高志英

Owner ZHEJIANG TWIN LANTERN HOME TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com