Jar external circulatory packed bed type cell reactor and method for cultivating animal cell

A cell reactor, animal cell technology, applied in animal cells, tissue cell/virus culture devices, biochemical equipment and methods, etc., can solve the problems of low dissolved oxygen level, microbial contamination, low expression, etc. Survival conditions, high degree of imitation of life, and rapid oxygen dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

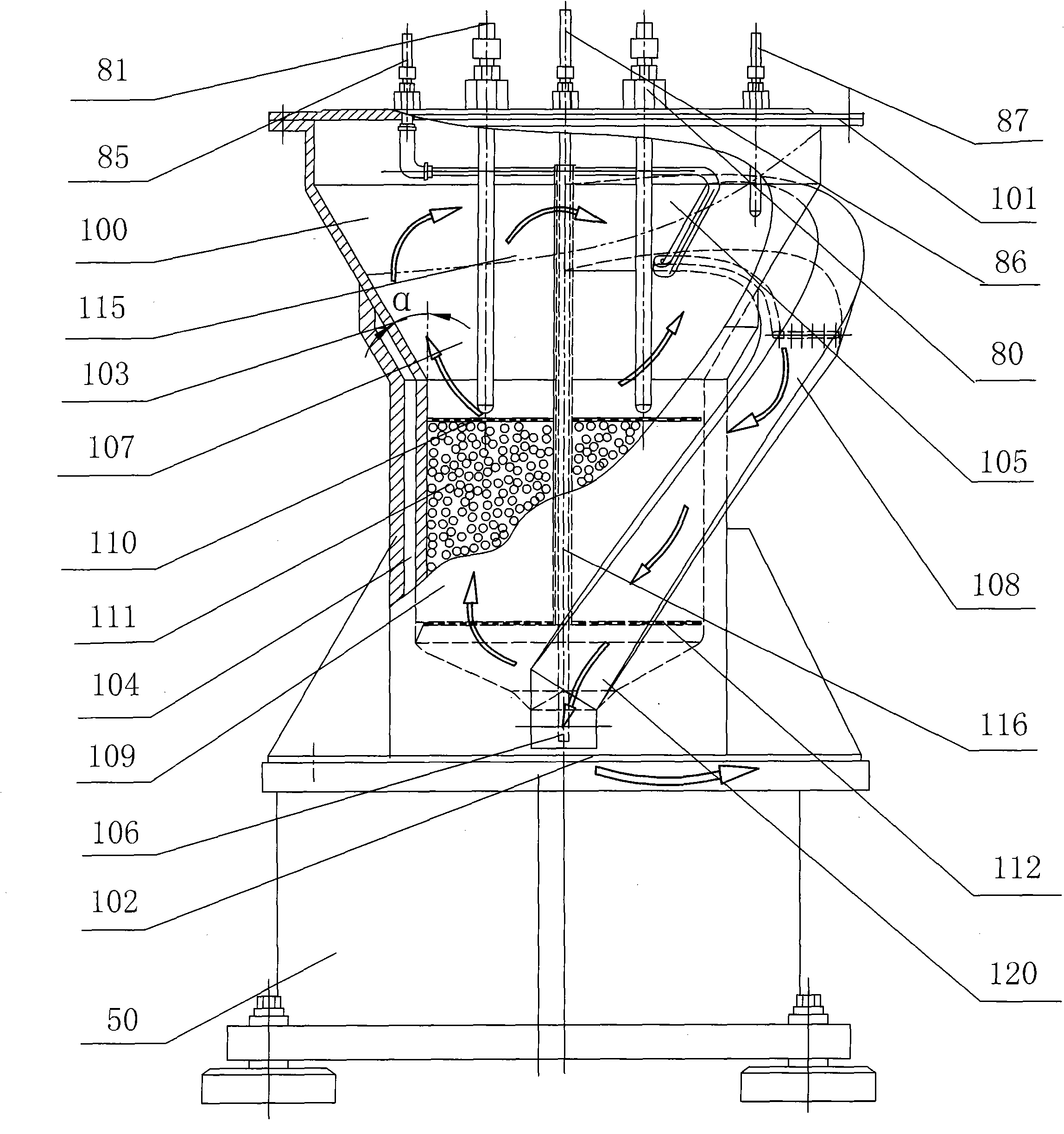

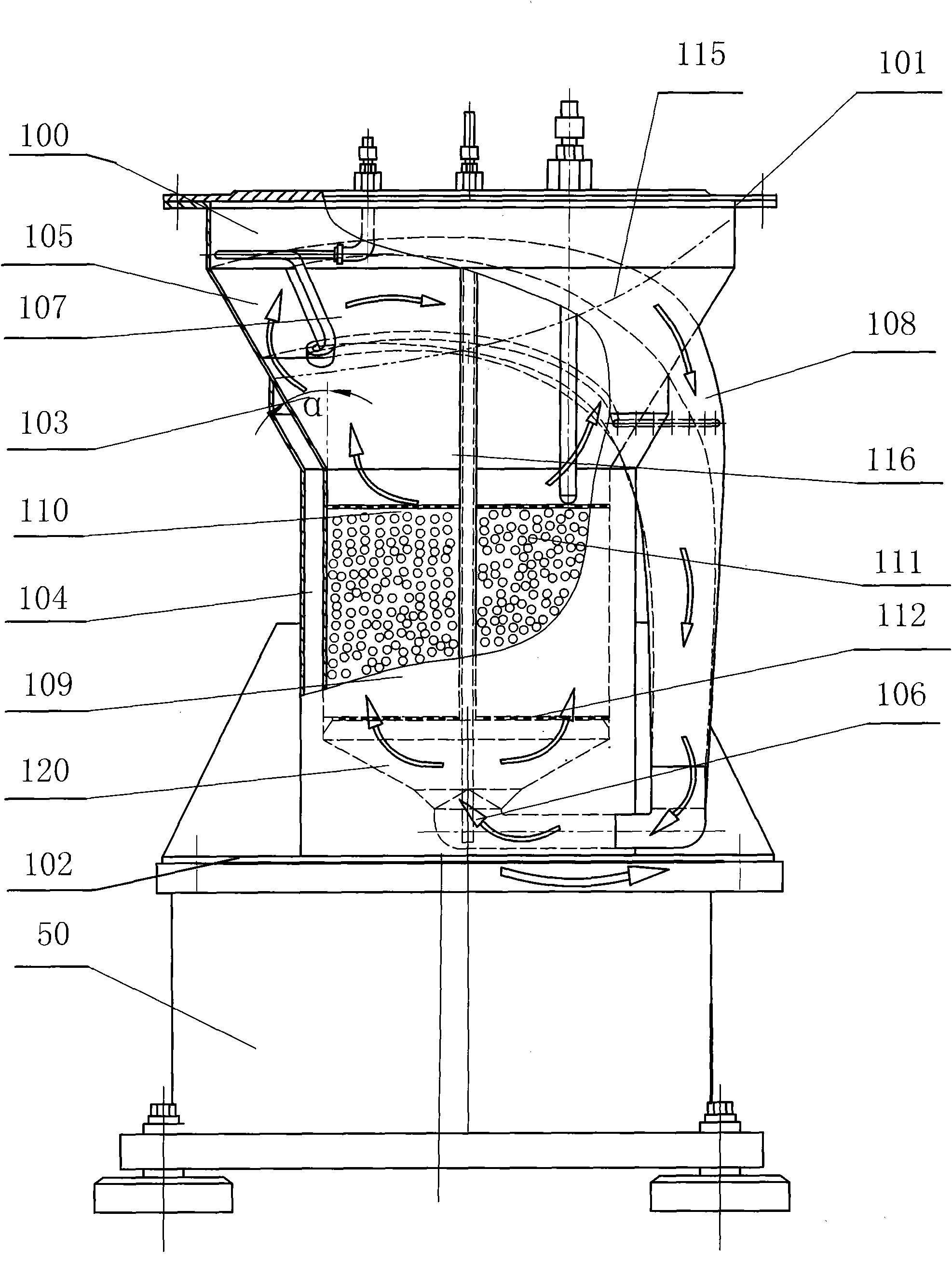

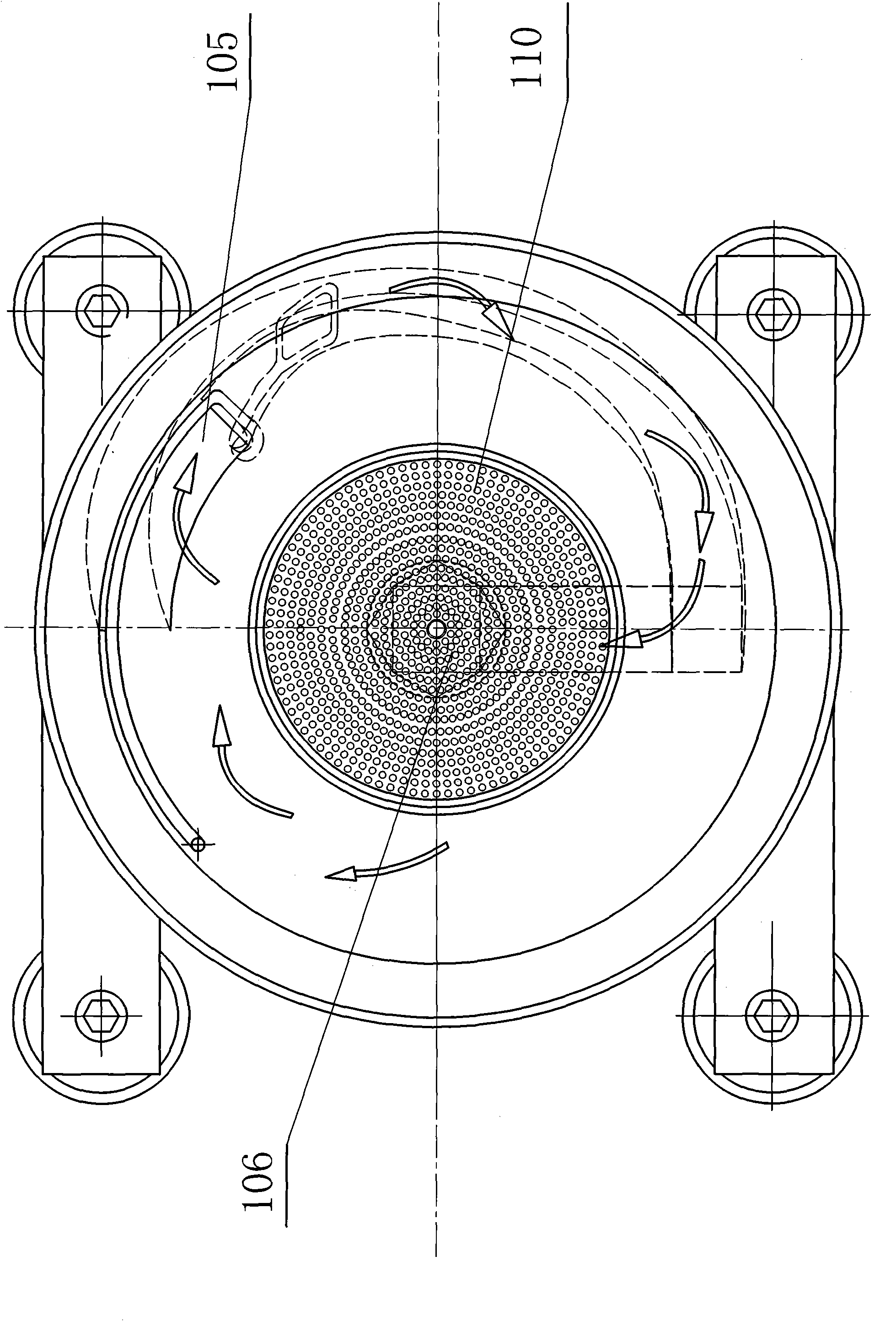

[0021] The packed-bed cell reactor with external circulation of the tank comprises: a reaction tank body 100 connected to a shaker 50, and shaking of the shaker makes the reaction tank rotate eccentrically. The upper part of the reaction tank body 100 is in the shape of a truncated cone 107, the lower part is in the shape of a cylinder 109, and the bottom is in the shape of a cone 120. The upper part of the described truncated cone is provided with an outer conduit inlet 105, and the outer conduit is unscrewed around the tank outside the tank. And return to the tank at the bottom, the outer conduit is around the tank body 1800 outside the tank, and the liquid return port 106 of the outer conduit enters the reaction tank at the center of the bottom of the tank, and the reaction The upper cover of the tank body has a tank cover with an air inlet pipe 85, a liquid outlet pipe 86, a liquid inlet pipe 87, a dissolved oxygen probe 80, and a pH probe 81 pass through the tank cover and...

Embodiment 2

[0023] The packed bed type cell reactor with circulation outside the tank of Example 1, the packed bed includes an upper orifice plate 110 , a lower orifice plate 112 , an empty casing 115 and a sheet microcarrier 111 . The cylindrical 109 inner wall of the reaction tank body 100 is connected with the lower orifice 112 and the empty casing 115, the upper end of the empty casing 115 is connected with the upper orifice 110, the upper orifice 110, the empty casing 115 , The lower orifice plate 112 constitutes a packed bed, and the sheet microcarrier 111 is filled between the lower orifice plate and the upper orifice plate. The packed bed is consistent with the center line of the reaction tank body 100 . The reaction tank has a chassis 102, the reaction tank 110 is connected to the shaking plate 50 through the chassis 102, the reaction tank body 100 is equipped with a top cover 101, and the reaction tank body 100 is connected to the upper The covers are connected with bolts.

[...

Embodiment 3

[0026] In the packed bed cell reactor with external circulation of the tank described in embodiment 1 or 2, the semi-vertical angle α of the surface of the upper frustum of the reaction tank body is 25° to 55°, such as 30° or 35°, 40°, 45° or 50° can be determined through experiments according to the dissolved oxygen level of the required nutrient solution and the required circulation speed. Generally, it is better between 30-42°. The outside of the reaction tank has Thermal insulation water jacket 104.

[0027] The packed bed cell reactor with external circulation of the tank, the tank body of the reaction tank and the shaker are fixed with bolts; the tank body and the upper cover are sealed with an "O" rubber ring; The cylinder at the lower part of the reaction tank has rounded corners and transitions to a conical bottom, and the inner bottom of the reaction tank has a conical shape, which is connected to the lower end of the outer conduit through a round sky structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com