Liquid crystal composition for TFT (Thin-Film Transistor) display

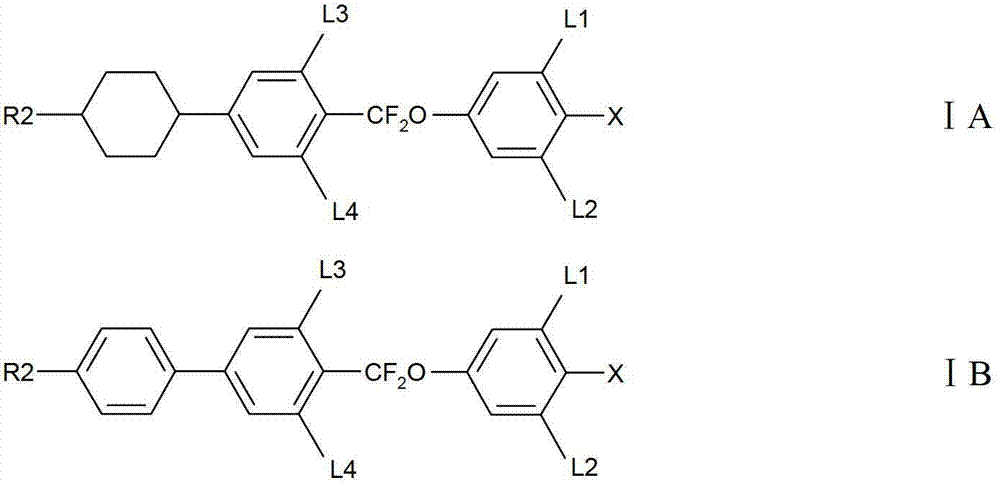

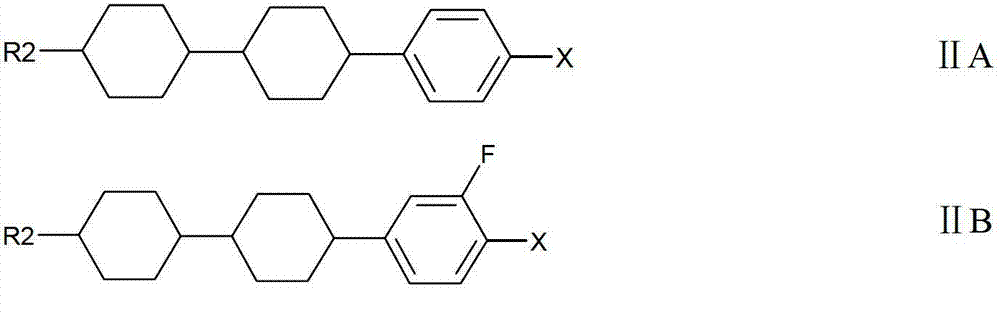

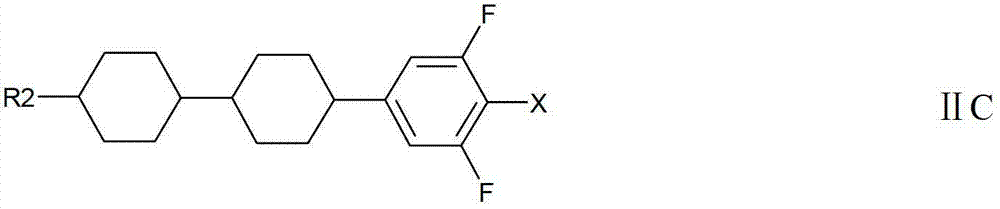

A liquid crystal composition and composition technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of TFT-LCD such as insufficient fast response, insufficient voltage, insufficient charge retention rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Take the following compositions I, II, III, IV, V, and optically active compound S2011 in the following weight percentages to prepare a liquid crystal composition. The specific ratio is shown in Table 1, and the properties of the obtained liquid crystal composition are also shown in Table 1:

[0110] Table 1 Proportion and performance parameters of the liquid crystal composition of Example 1

[0111] IIB-9 20% V 10 [V, 20°C] 1.40

[0112]IV-3 11% τ[ms] 49

[0113] IV-4 10% η [mm 2 / s, 20°C] 17.9

[0114] IIC-2 6% Cp[°C] 89.8

[0115] IIC-4 5% Δn[20°C, 589nm] 0.088

[0116] IIIA-6 4%

[0117] IIIA-8 4%

[0118] IIIA-14 7%

[0119] IIA-3 5%

[0120] IIA-4 5%

[0121] IA-3 5%

[0122] IB-3 5%

[0123] IIC-6 8%

[0124] VC-2 5%

[0125] S2011 0.1%

Embodiment 2

[0127] Take the following compositions I, II, III, IV, V, and optically active compound S2011 in the following weight percentages to configure a liquid crystal composition. The specific ratio is shown in Table 2, and the properties of the obtained liquid crystal composition are also shown in Table 2:

[0128] Table 2 The ratio and performance parameters of the liquid crystal composition of Example 2

[0129] IIB-9 20% V 10 [V, 20°C] 1.45

[0130] IV-3 15% τ[ms, 20°C] 45

[0131] IV-4 11% η [mm 2 / s, 20°C] 16.8

[0132] IIC-2 5% Cp[°C] 91.1

[0133] IIC-4 6% Δn[20°C, 589nm] 0.086

[0134] IIIA-6 2%

[0135] IIIA-8 4%

[0136] IIIA-14 5%

[0137] IIA-3 5%

[0138] IIA-4 5%

[0139] IA-3 5%

[0140] IB-3 5%

[0141] IIC-6 5%

[0142] VC-2 7%

[0143] S2011 0.14%

Embodiment 3

[0145] Take the following compositions I, II, III, IV, V, and optically active compound S2011 in the following weight percentages to configure a liquid crystal composition. The specific ratio is shown in Table 3, and the properties of the obtained liquid crystal composition are also shown in Table 3:

[0146] Table 3 The ratio and performance parameters of the liquid crystal composition of Example 3

[0147] IIB-9 15% V 10 [V, 20°C] 1.82

[0148] IIA-1 9% τ[ms] 50

[0149] IV-3 9% η [mm 2 / s, 20°C] 16.7

[0150] IV-4 10% Cp[°C] 86.9

[0151] IIIB-2 2% Δn[20°C, 589nm] 0.103

[0152] IIIB-3 3%

[0153] IIIA-4 5%

[0154] IIC-2 3%

[0155] IIC-4 4%

[0156] IIIA-6 5%

[0157] IIIA-8 5%

[0158] IIIA-14 5%

[0159] IIB-12 3%

[0160] IIA-3 4%

[0161] IIA-4 4%

[0162] IIC-6 3%

[0163] IA-3 5%

[0164] IB-3 6%

[0165] S811 0.12%

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com