Aggregate for lowering pavement temperature and method for preparing bitumen mixture by utilizing same

A technology for asphalt mixture and pavement temperature, applied in sustainable waste treatment, solid waste management, climate change adaptation, etc., can solve problems such as hazards, high stone cost, and high thermal conductivity of wear layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1: The aggregates for reducing the temperature of the road surface in this embodiment are waste ceramic particles with a particle size of 4.75 mm to 9.5 mm.

[0014] The aggregate for reducing the temperature of the road surface in this embodiment is obtained by crushing and grinding waste ceramics, and the cost is 3 to 4 yuan / cubic meter, which is 80% to 90% lower than the cost of stone aggregates of the same volume The pottery is a kind of material with lower thermal conductivity, and the aggregate that reduces the temperature of the pavement of the present invention is used to replace part of the stone aggregate in the conventional aggregate to prepare an asphalt mixture, and use the asphalt mixture to adopt a conventional method to pave the road Therefore, the thermal properties of the wearing layer are changed, and the thermal conductivity of the wearing layer is reduced from 1.000W / m·℃~1.020W / m·℃ to 0.680W / m·℃~0.690W / m·℃. The temperature difference betw...

specific Embodiment approach 2

[0015] Embodiment 2: The waste ceramic particles in this embodiment are one or a combination of architectural ceramics, household ceramics, sanitary ceramics and sanitary products. Others are the same as in the first embodiment.

[0016] When the ceramics of this embodiment are a composition, ceramics are combined in arbitrary ratios.

specific Embodiment approach 3

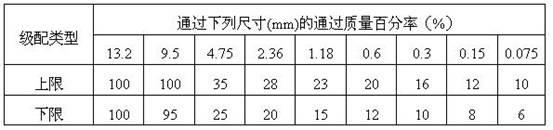

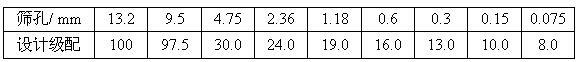

[0017] Specific implementation mode three: the method for preparing asphalt mixture by utilizing aggregates that reduce the temperature of the road surface in this embodiment is carried out in the following steps: one, calculate the stone material consumption according to the SAC-10 mineral material gradation; two, use the described method of claim 1 The aggregate for lowering the temperature of the road surface replaces 18% to 22% (volume) of the stone with a particle size of 4.75mm to 9.5mm calculated in step 1, then weighs the stone and the aggregate for lowering the temperature of the road surface, and mixes them evenly to obtain a mixed Aggregate; 3. Prepare 86.8% to 88.1% mixed aggregate, 5.5% to 6% mineral powder, 1.8% to 2.2% slaked lime and 4.6% to 5% asphalt to prepare asphalt mixture according to the mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com