Low-temperature land fluid assembly and disassembly arm

A fluid loading and unloading arm, low temperature technology, used in liquid distribution, conveying or transfer devices, packaging, distribution devices, etc., can solve the problems of inflexible rotation of rotary joints, uneven deformation of sealing surfaces, and inability to ensure low temperature sealing. , to solve the problem of low temperature sealing, solve uneven deformation, and achieve the effect of flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

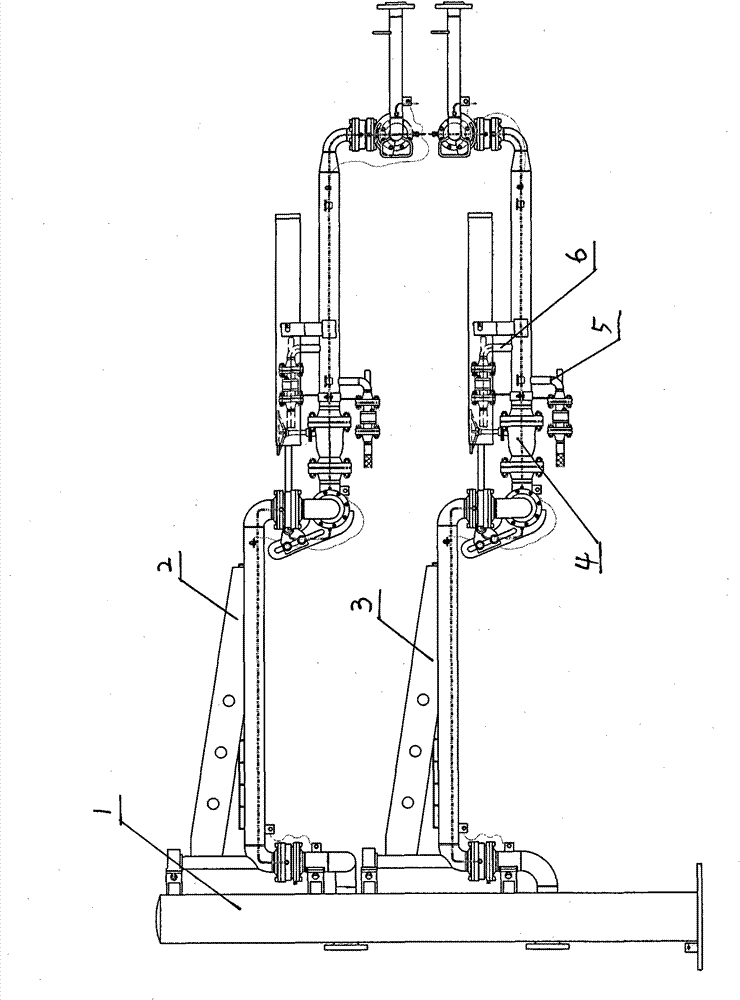

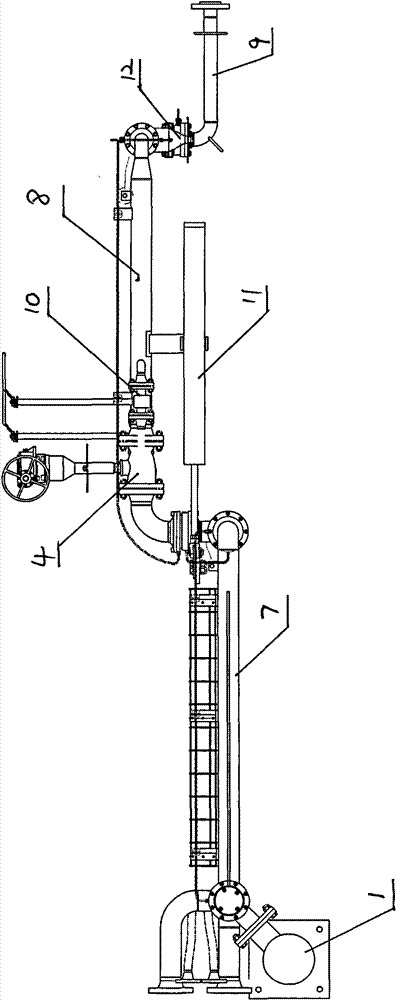

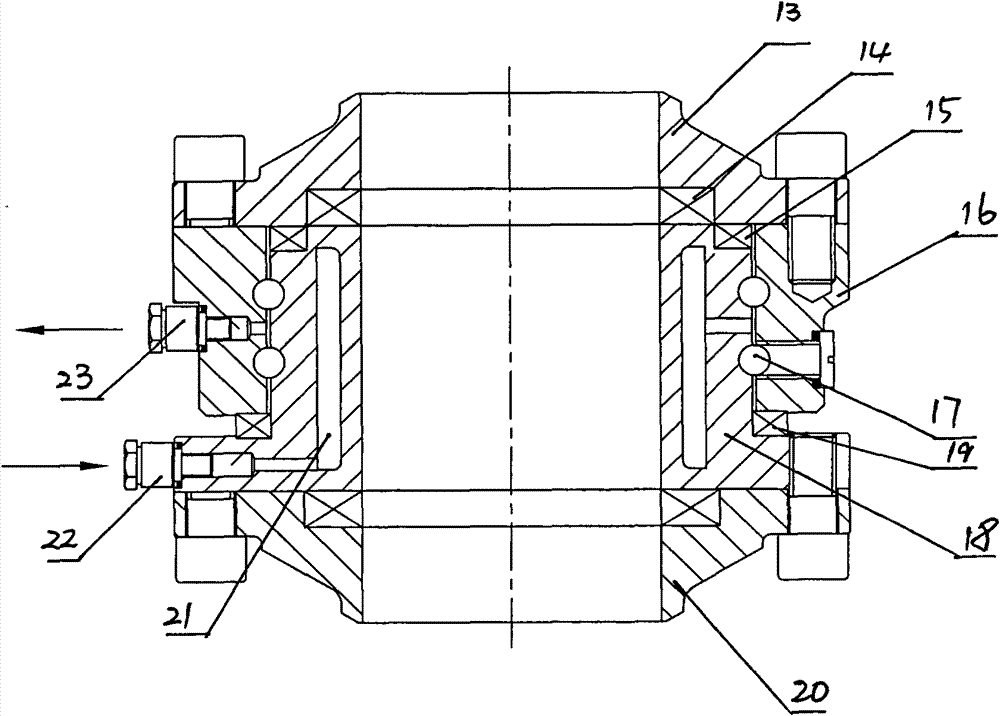

[0014] A low-temperature land-use fluid loading and unloading arm, which is provided with a column 1, a liquid phase arm 3 and a gas phase arm 2 mounted on the column 1, and the liquid phase arm 3 and the gas phase arm 2 both include an inner arm 7, an outer arm 8 and a vertical pipe 9 , between the inner arm 7 and the column 1, between the outer arm 8 and the inner arm 7, and between the outer arm 8 and the vertical pipe 9 are all connected by rotary joints, the liquid phase arm and the gas phase arm are arranged side by side up and down, near the inner wall of the outer arm A low temperature valve 4 for vehicle loading is installed at the end, and the front end of the low temperature valve 4 is provided with a purge device 10 for replacement, and the rotary joint is provided with a nitrogen purge mechanism. The rotary joint nitrogen purging mechanism adopts a rigid design, starting from the first rotary joint in series to the most end rotary joint. The structural form with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com