Active type coil spring suspension

A coil spring and active technology, applied in the field of coil spring suspension, can solve the problems of shortening the service life of the air pump, overheating of the air pump system, high production cost, etc., and achieve the effect of overcoming the inability to adjust, low failure rate, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

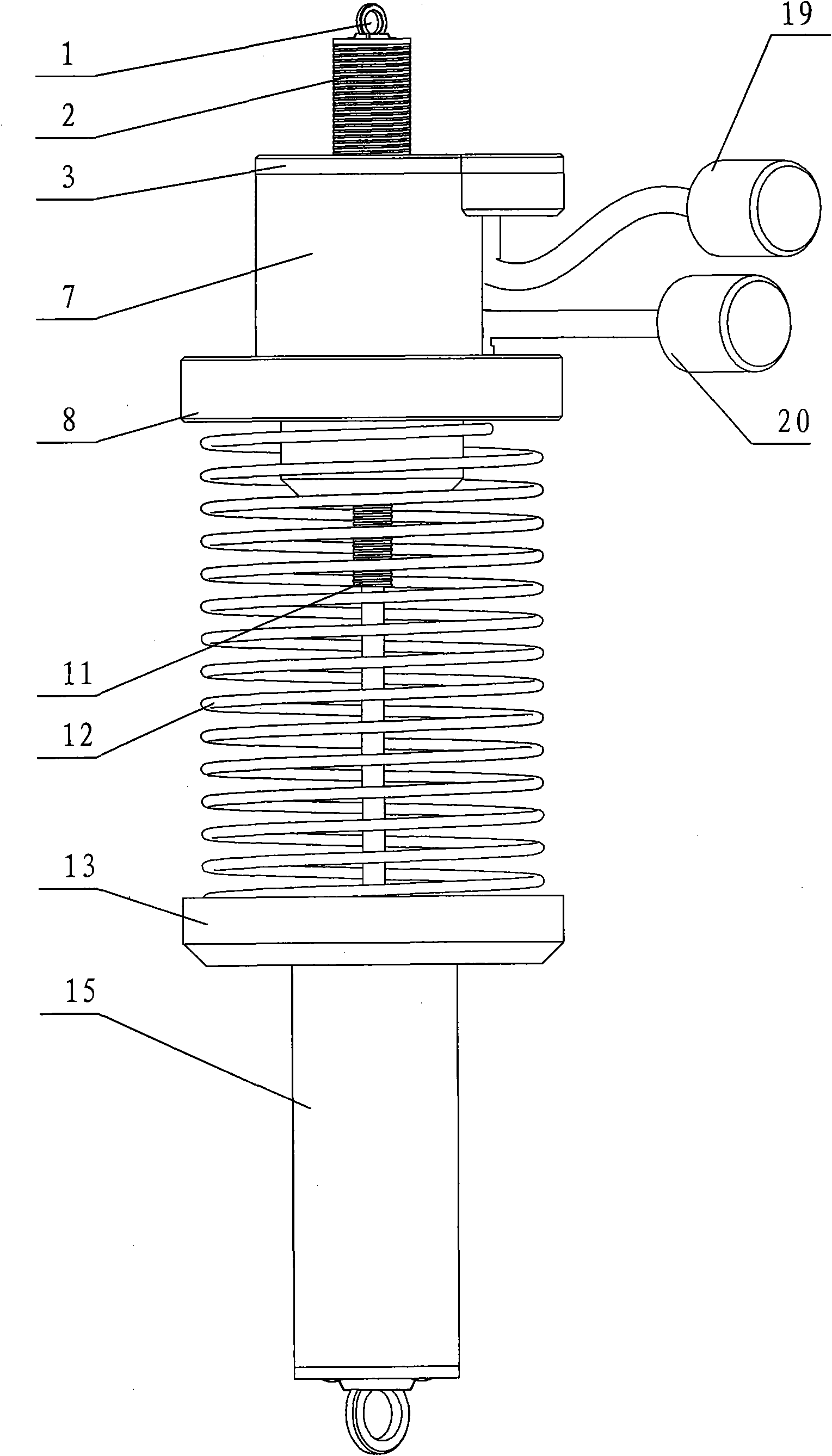

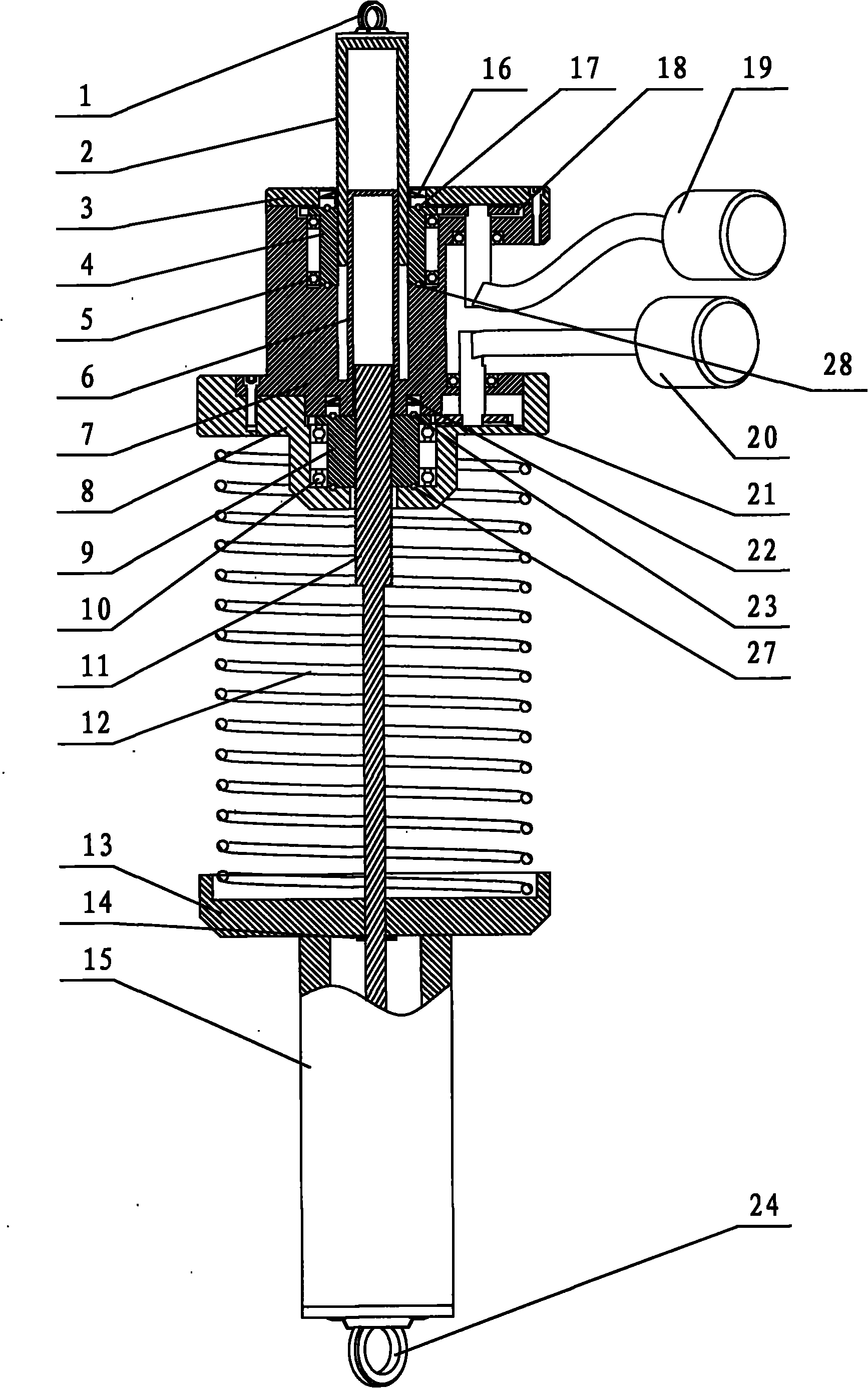

[0031] Figure 1 to Figure 4 Shown, for the present invention creates the first kind of specific embodiment of active coil spring suspension, it comprises spring preload adjusting device, suspension height adjusting device and shock absorber 15, and described spring preload adjusting device comprises Upper spring seat 8, coil spring 12, lower spring seat 13, pull bar 11, pre-tightening driven gear 9 and pre-tightening power device, described shock absorber 15 is fixed on the lower spring seat 13, upper spring seat 8 and lower spring The seat 13 clamps the coil spring 12 in the middle to form a support for the coil spring 12; the outer ring of the preload driven gear 9 is rotatably installed on the upper spring seat 8 through the upper and lower bearings 10, and the preload driven gear 9 is internally provided with Internal thread, the outer surface of the uppermost end of the pull rod 11 is a smooth cylinder, the outer surface of the lower part of the cylinder is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com