Pumping device and system for jet stirring of ammonium nitrate solution

A technology of ammonium nitrate solution and pumping device, which is applied in the fields of pumping and chemical solution stirring, which can solve the problems of unsafety, cooling, crystallization, easy to be burned, etc., achieve convenient maintenance, prevent pipeline crystallization, and avoid siphon phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

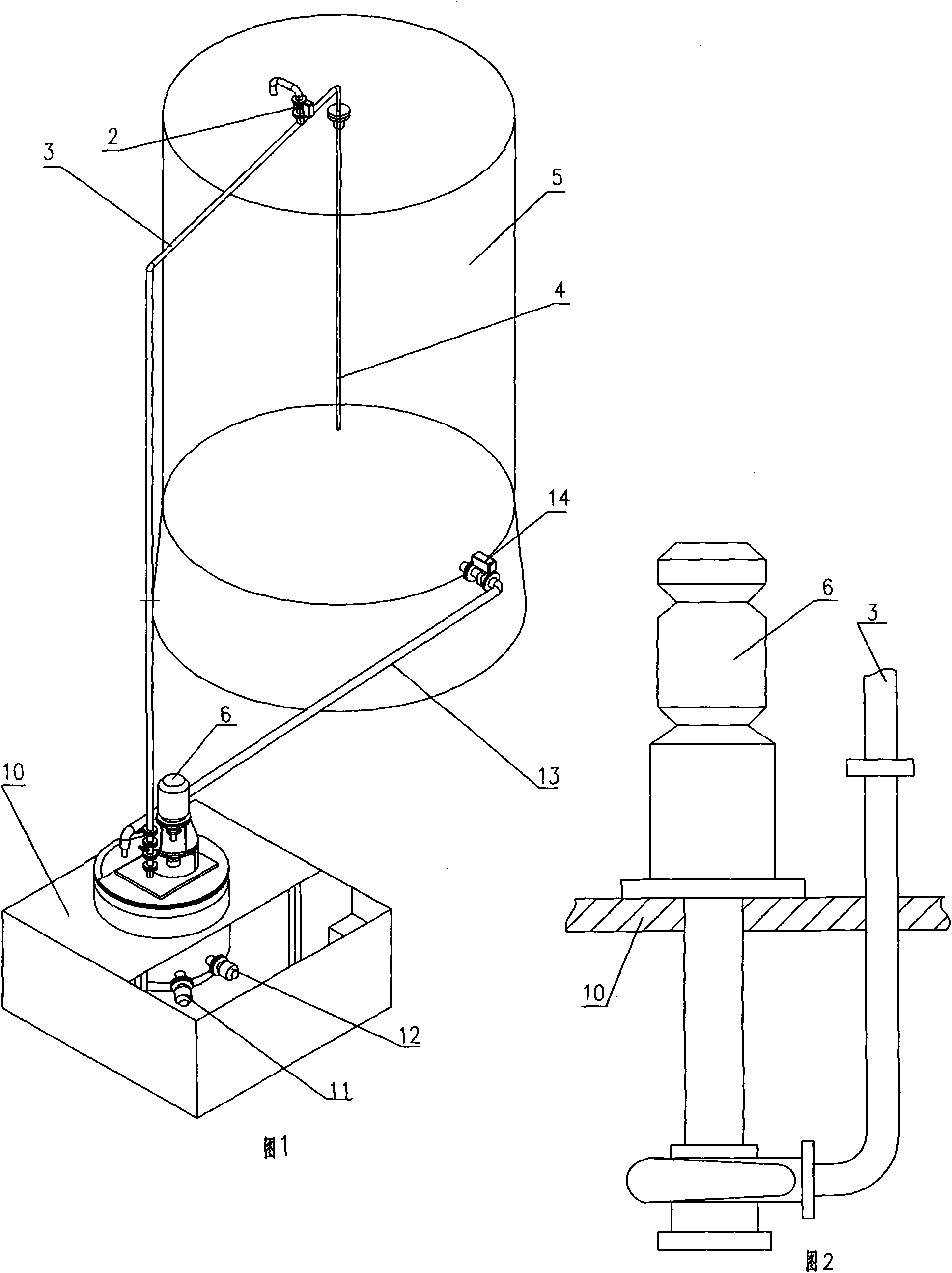

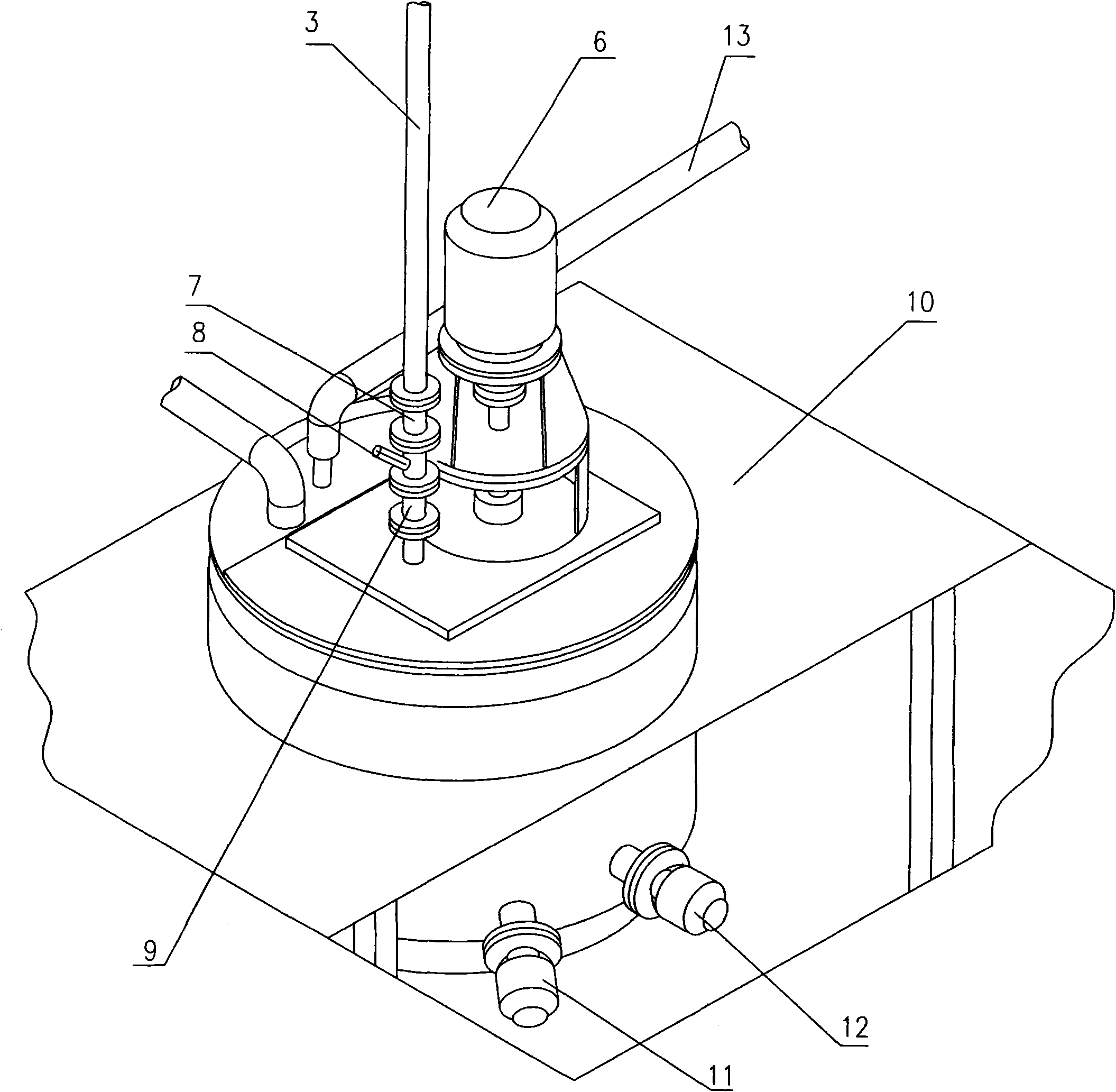

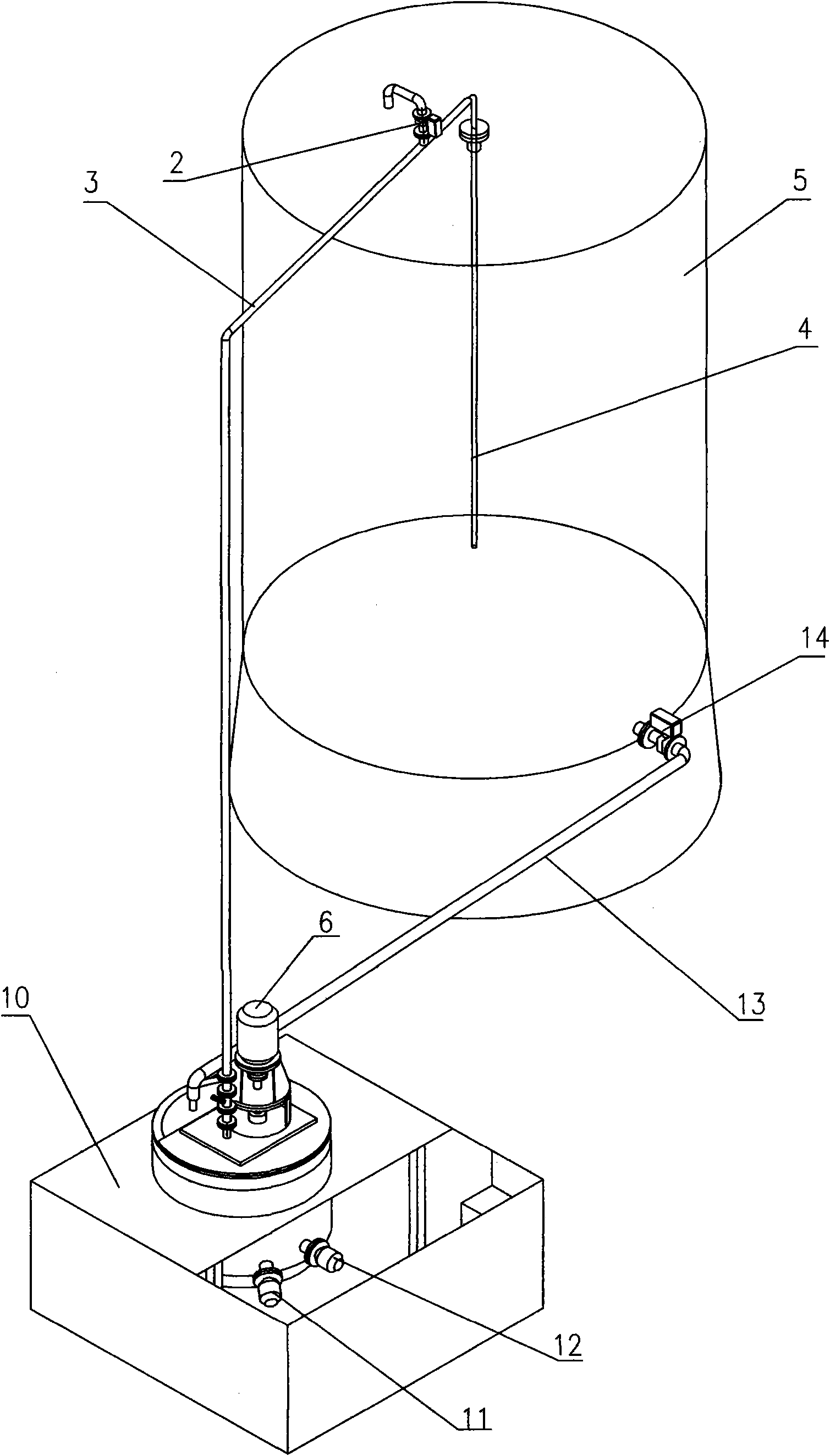

[0012] The structure of the present invention includes a storage tank (5), a return pipe (3) of the storage tank (5), a discharge pipe (13), a jet nozzle (4) and a working pump, and is characterized by; beside the storage tank (5) A reflux tank (10) is provided, the top cover of the reflux tank (10) is lower than the discharge pipe (13) of the storage tank (5); the top cover of the reflux tank (10) is installed with a chemical anticorrosive liquid as a working pump The motor drive mechanism of the lower pump (6) and the submerged pump (6) is fixed on the top cover, and the pump body of the submerged pump (6) extends into the reflux tank (10) and then hangs in the tank cavity; storage tank (5) The discharge port of the discharge pipe (13) is connected with the feed port pipeline on the top cover of the return tank (10), and the feed port of the return pipe (3) of the storage tank (5) is connected to the submerged pump ( 6) The discharge port is connected; the discharge pipe (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com