Natural perfume preparation method and equipment

A natural fragrance and equipment technology, applied in the field of natural fragrance preparation, can solve the problems of not collecting essential oil, single function, unable to meet the industrialized demand of multi-batch production of essential oil and extract, and achieve the effect of avoiding siphon phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Another embodiment of the present invention provides a method for preparing natural spices, comprising the following steps:

[0067] The natural fragrance preparation equipment provided by any technical solution of the present invention is used to extract natural fragrance in multiple batches according to the natural fragrance extraction process.

[0068] Multi-batch refers to two or more times. Of course, the natural fragrance preparation equipment provided by any technical solution of the present invention can also realize the single-batch extraction of natural fragrance.

[0069] The natural fragrance extraction process here includes plant essential oil extraction process and tincture extraction process. The details of these two processes are described above.

[0070] Further, the natural fragrance is plant essential oil, the first channel 4 of the natural fragrance preparation equipment is connected, and the natural fragrance preparation method further includes the...

Embodiment 1

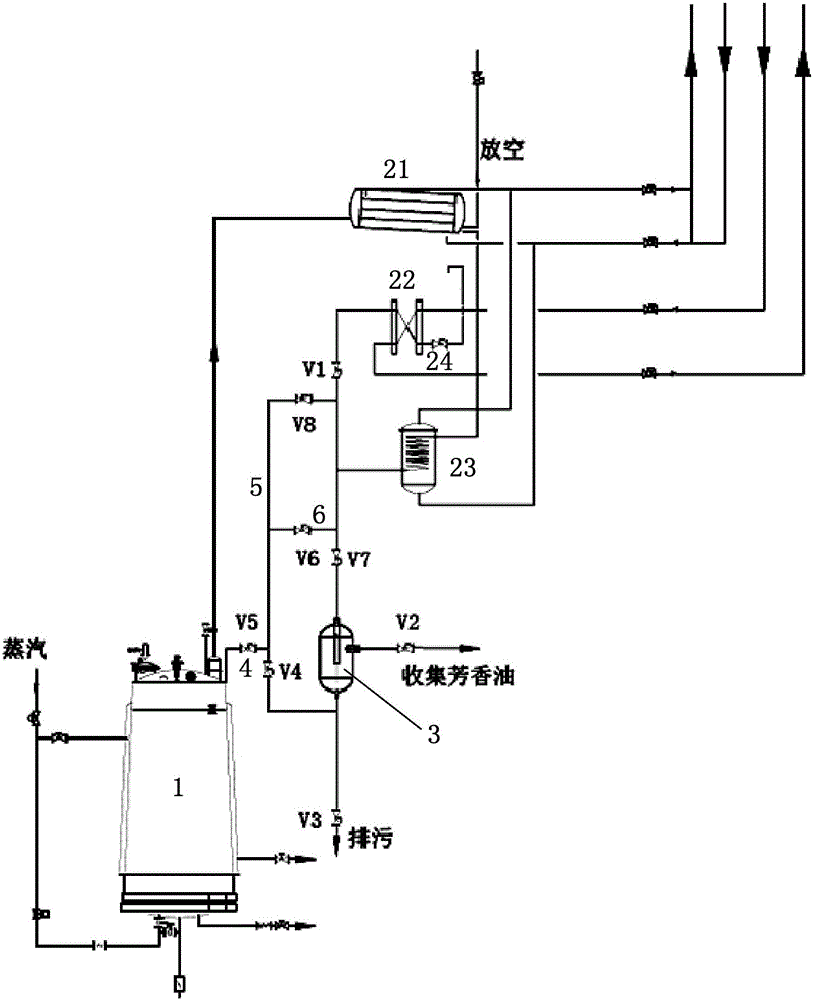

[0079] Example 1: Preparation of Sanming Youxi Tobacco Essential Oil and Water Extract

[0080] Sanming Youxi tobacco leaves are threshed and re-roasted, Fujian China Tobacco Industry Co., Ltd.; steam, Xiamen Guoneng Tongji Thermal Power Co., Ltd.

[0081] according to figure 1 According to the technological process, 20Kg Sanming Youxi tobacco leaves are heated and extracted in the tank 1, and the control valves V1, V4, V7, V5 and V8 are opened; the control valves V2, V3 and V6 are closed. Start the extraction tank 1 jacketed steam heating equipment, the valve opening is 80%, and the set temperature is 80°C. After reaching the set temperature, open the bottom direct steam heating device, and the valve opening is 30%. The condensation flow of condensate can be 40Kg / hour; after the parameters are stable, the running time is 4 hours. There is an oil layer in the oil-water separator 3, and the second control valve V2 is opened to collect essential oil products.

[0082] Then a...

Embodiment 2

[0085] Embodiment 2: the preparation of tea tree flower essential oil and alcohol extract

[0086]Fresh tea tree flowers, freshly picked from Fujian Anxi Tieguanyin Tea Mountain; steam, Xiamen Guoneng Tongji Thermal Power Co., Ltd.

[0087] see figure 1 , 30Kg of fresh tea tree flowers are added to the extraction tank 1, and the control valves V1, V4, V7, V5 and V8 are opened; the control valves V2, V3 and V6 are closed. Start the jacketed steam heating equipment of the extraction tank 1, the valve opening is 60%, and the set temperature is 60°C. After reaching the set temperature, open the bottom direct steam heating device, and the valve opening is 20%. Condensate flow can be 30Kg / hour. After the parameters are stable, the running time is 6 hours. There is an oil layer in the oil-water separator 3 .

[0088] Then 140Kg of 95% ethanol is added to the extraction tank 1, the control valves V1, V5, V6 and V8 are opened, and the control valves V2, V3, V4 and V7 are closed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com