Back-washable flat membrane element

A flat membrane and element technology, applied in the field of membrane separation technology research and development and application, can solve the problems of increased filtration resistance, damage to flat membrane elements, flat membrane cracks, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

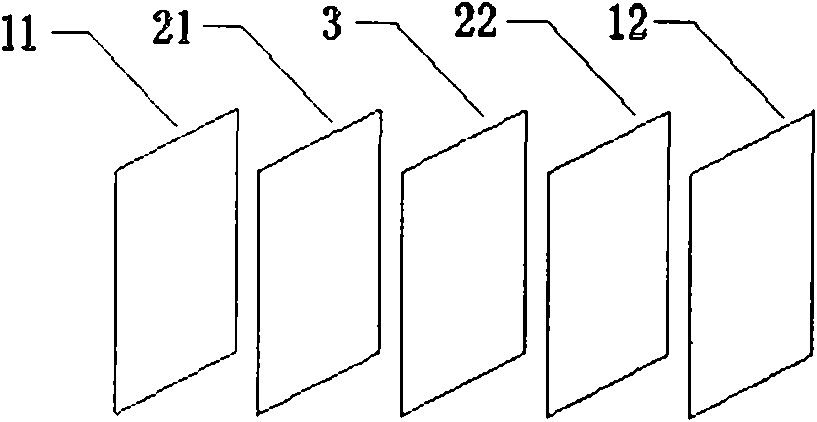

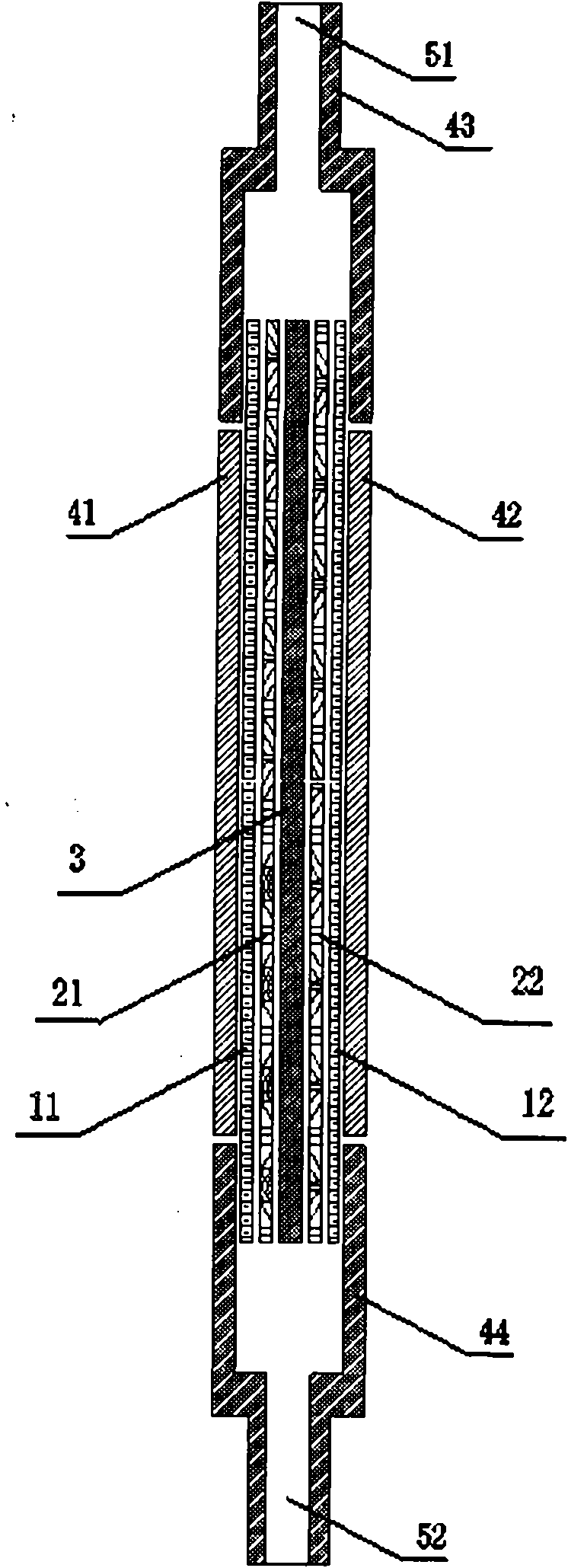

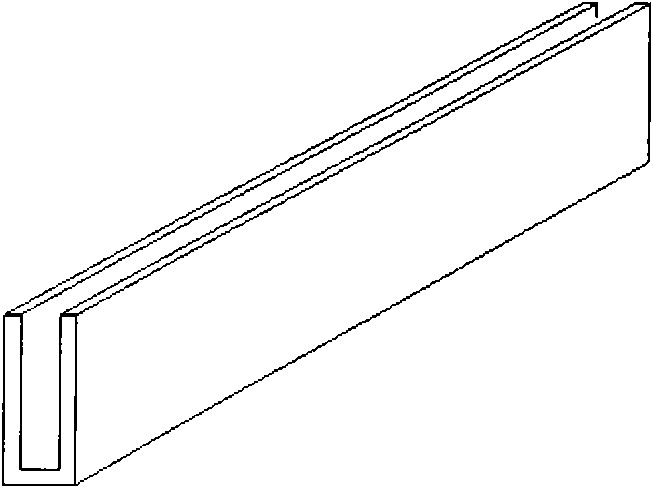

[0022] The present invention proposes that the backwashable flat membrane element includes a backwash protection net, a flat membrane, a diversion net, a support plate, a U-shaped sealing groove, a water inlet and outlet, and a fixed ring. The backwashable flat membrane element is in the order of the first backwash protection net, the first flat membrane, the first diversion layer, the support plate, the second diversion net, the second flat membrane, and the second backwash protection net Superposition, after superimposition, the surrounding area is sealed by U-shaped sealing grooves, and bonding is carried out in U-shaped sealing grooves: in the U-shaped sealing grooves in the left and right directions and only in the grooves, there is sealant bonding between each layer, so that the The U-shaped groove at the place and the first backwash protection net, the first flat membrane, the first diversion layer, the support plate, the second diversion net, the second flat membrane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com