Pneumatic garlic seeder

A pneumatic seeder technology, which is applied in the field of agricultural machinery, can solve problems such as damage, and achieve the effects of uniform seeding depth, improved operating efficiency, and accurate seed picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is further described.

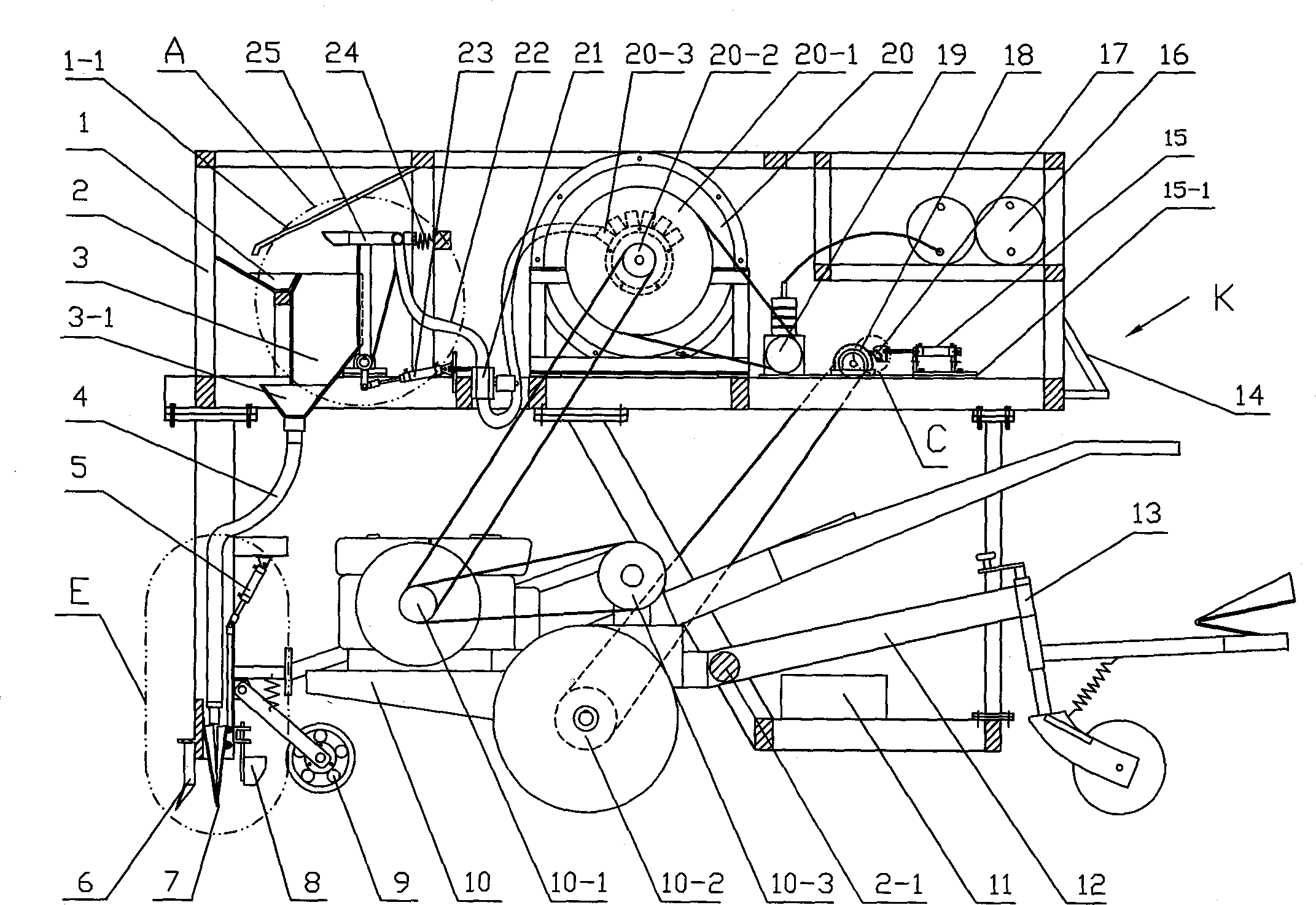

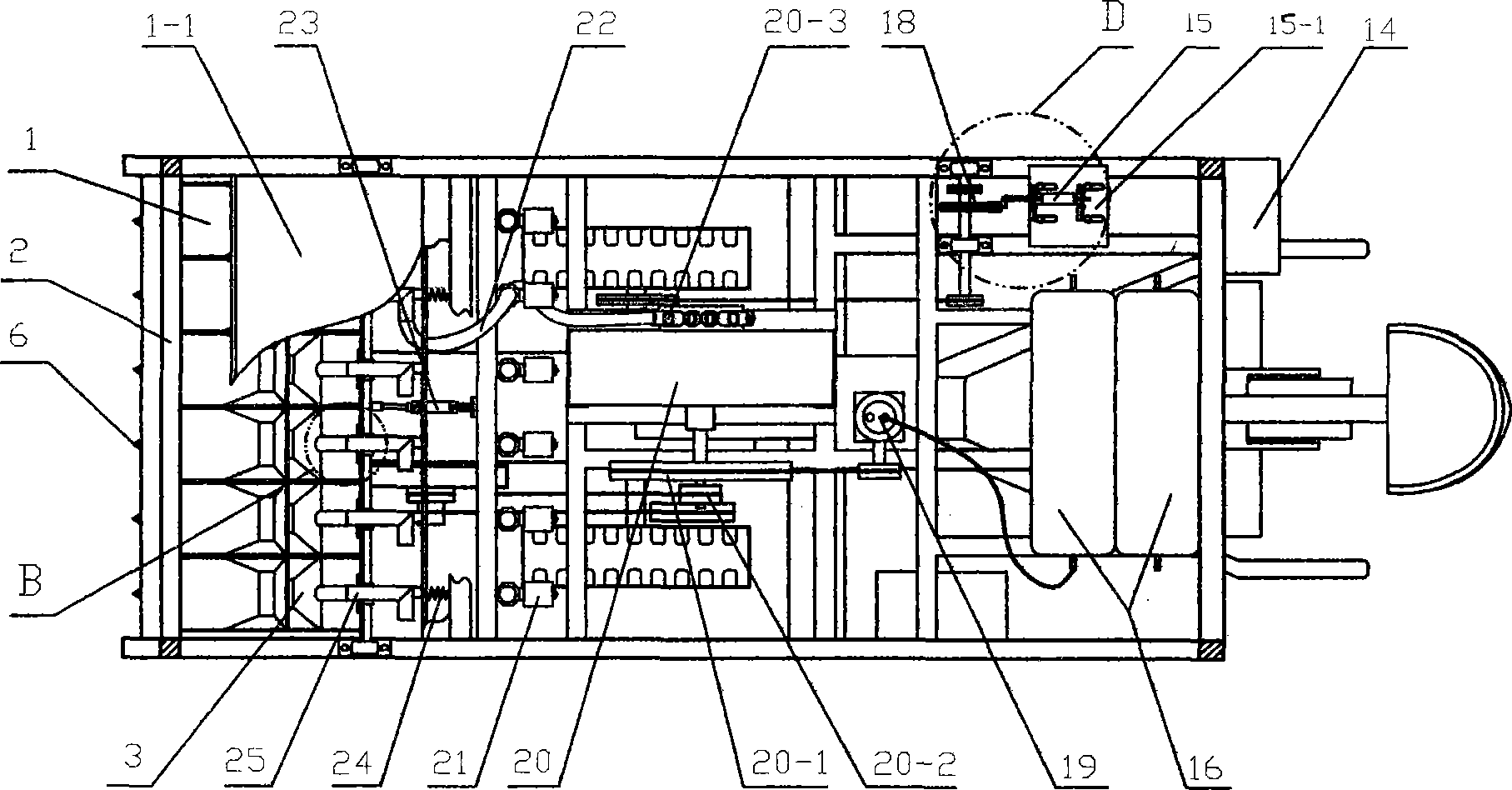

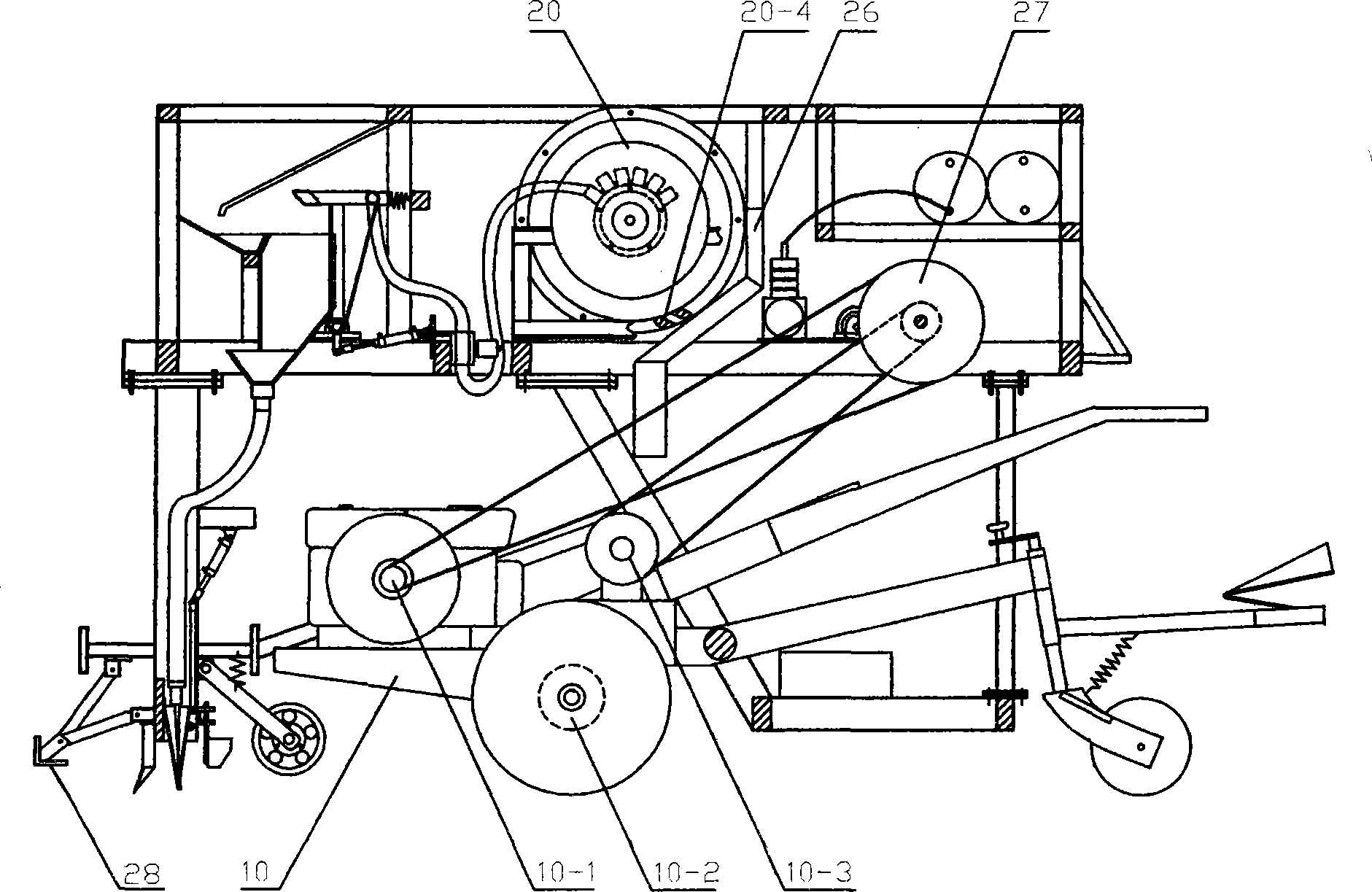

[0038] Pneumatic garlic seeder as shown in the accompanying drawing, comprises frame 2, and there are a plurality of ditch openers 6, planter 7 and sealer 8 below the frame, suppressing roller 9 is arranged behind the sealer, and seed is arranged on frame 2 Box 1 and seed-taking and seed-discharging mechanism, the seed box is connected with seed delivery pipe 4, and the seed delivery pipe is connected with planter 7; A single planting group is formed; the frame 2 is connected with the tractor 10, the drive wheel 10-1 is arranged on the power output shaft of the tractor, the drive wheel is connected with the speed change mechanism 10-3 through the transmission device, and the speed change mechanism is connected with the tractor through the transmission device. Travel axles and travel wheels.

[0039] Such as figure 1 , figure 2 As shown, the frame 2 is a frame-shaped rectangular frame....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com