Method for quantitatively analyzing residual phosphorus oxychloride

A technology of phosphorus oxychloride and quantitative analysis, applied in the field of spectrophotometry, can solve the problems of affecting product quality, lack of clear and detailed analysis steps, general laboratories do not have large-scale instruments, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Experimental principle

[0013] Phosphorus oxychloride easily reacts with water to form orthophosphoric acid and hydrochloric acid:

[0014] POCl 3 +3H 2 O=H 3 PO 4 +3HCl

[0015] Ammonium molybdate spectrophotometric method was used to measure the phosphoric acid content (calculated as phosphorus) in the intermediate hydrolyzate, which was converted into the content of phosphorus oxychloride.

[0016] Orthophosphoric acid, ammonium molybdate, and ammonium metavanadate can form yellow complexes in acidic solutions:

[0017] 7H 3 PO 4 +7NH 4 VO 3 +16(NH 4 ) 6 Mo 7 o 24 4H 2 O+75HNO 3 →

[0018] 7[(NH 4 ) 3 PO 4 ·NH 4 VO 3 16MoO 3 ]+48H 2 O+75NH 4 NO 3

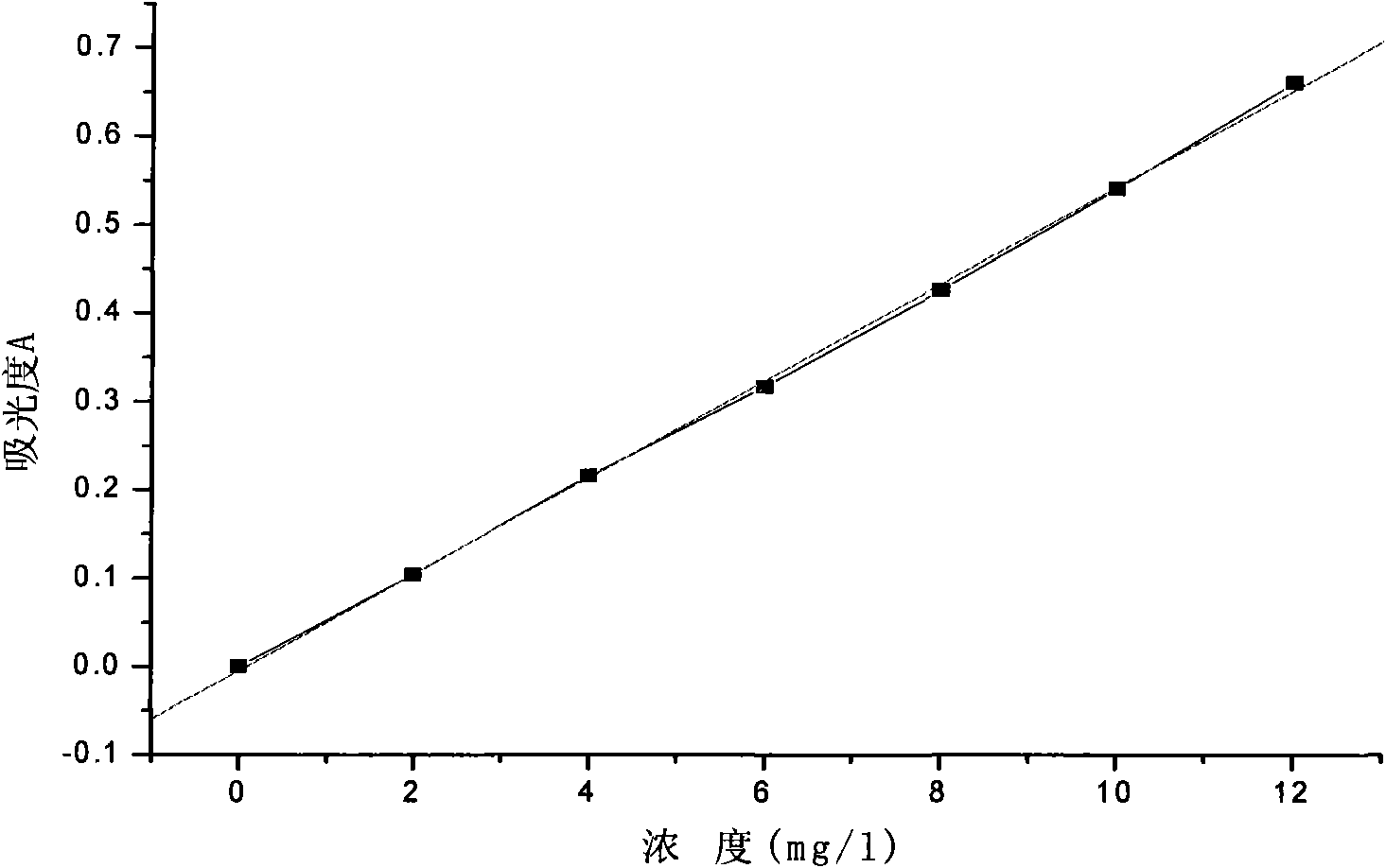

[0019] Measure the absorbance value of the yellow complex, compare with the standard working curve of phosphorus, and calculate the phosphorus concentration.

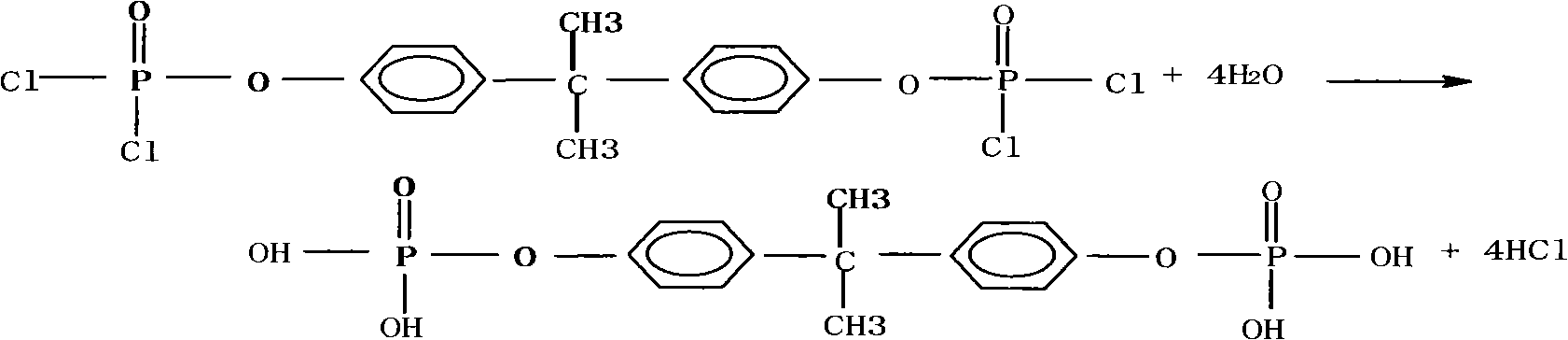

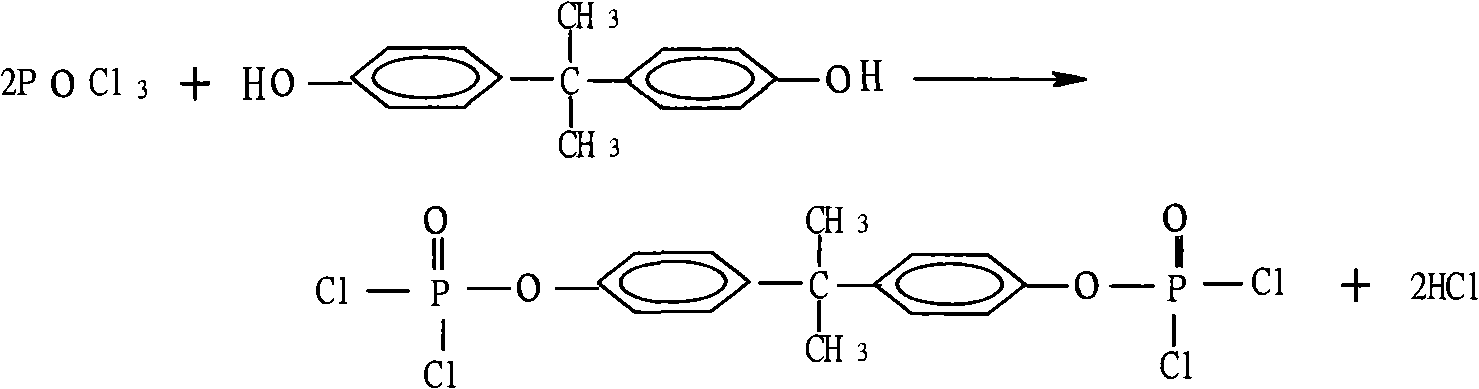

[0020] However, during the hydrolysis of phosphorus oxychloride, the intermediate acyl chloride (tetrachlorobisphenol A phosphate mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com