Whole railway traction locomotive tester

A technology for vehicle testing and railway traction, which can be used in railway vehicle testing and other directions to solve problems such as a large amount of external energy supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

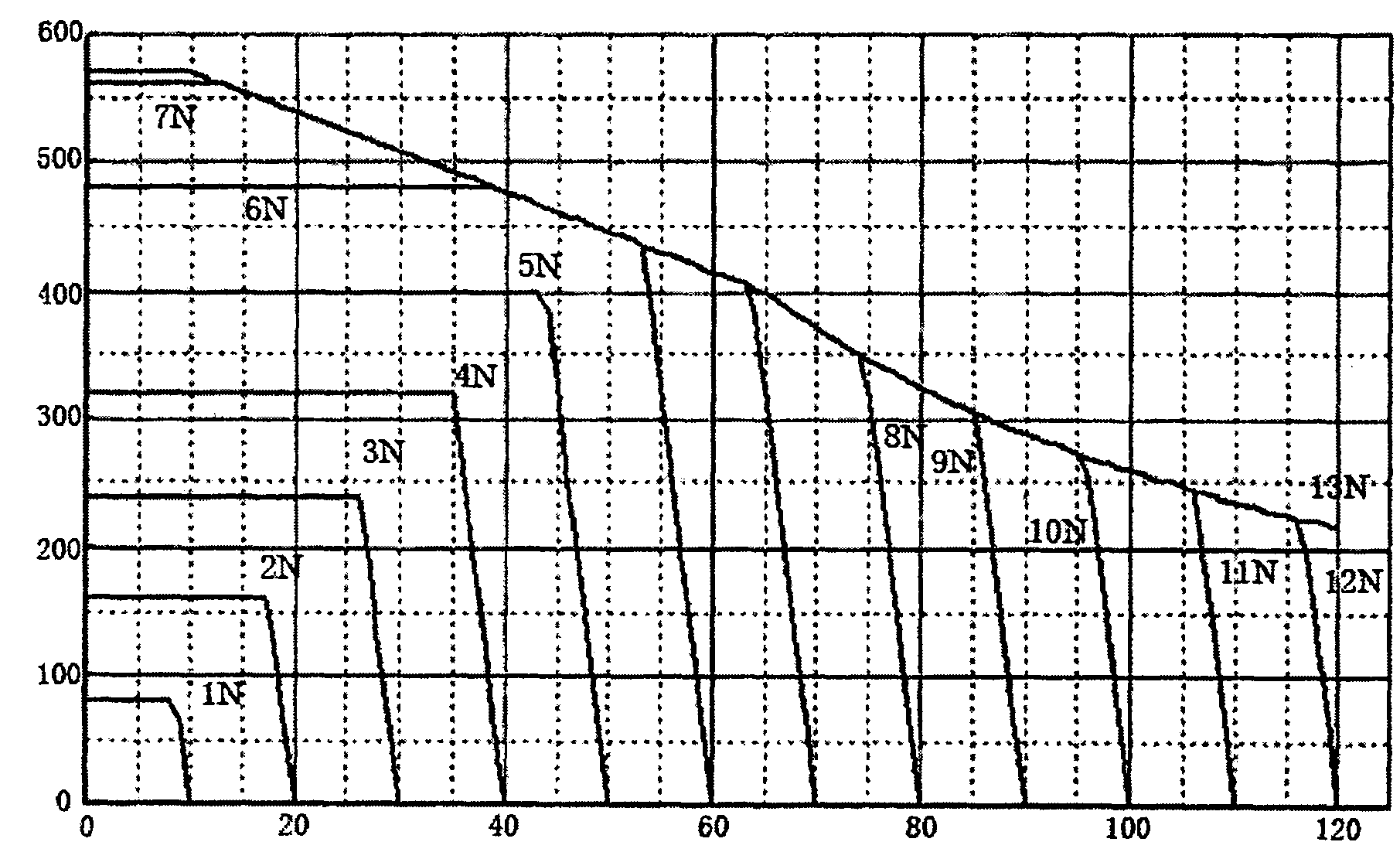

[0041] image 3 Shown is an embodiment of a uniaxial assembly of the present invention. The uniaxial assembly is composed of a track wheel 1 , a universal joint 2 , a synchronous gearbox 3 , a torque sensor 4 , and a flywheel 6 connected in sequence.

[0042] The dimension design of the flywheel 6 connected on the single shaft assembly is carried out below. Assume that the continuous running speed of the locomotive is 65km / h, the maximum speed is 120km / h, the power of the single-axis traction motor is 1600kw, and the mass of the train traction load shared by the single-axis traction motor is 1000T, and the maximum speed of the flywheel corresponding to the maximum speed is 3000 rev / min, then the rotating speed of the continuous speed under the same transmission ratio is about 1600 rev / min. by formula J = 2 · E / N · ω max 2 The calculated flywheel inertia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com