High-temperature and high-pressure small-size length measuring device

A length measuring device, high temperature and high pressure technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of electronic components such as temperature drift, failure to work, data errors, etc., to ensure accuracy, activity and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

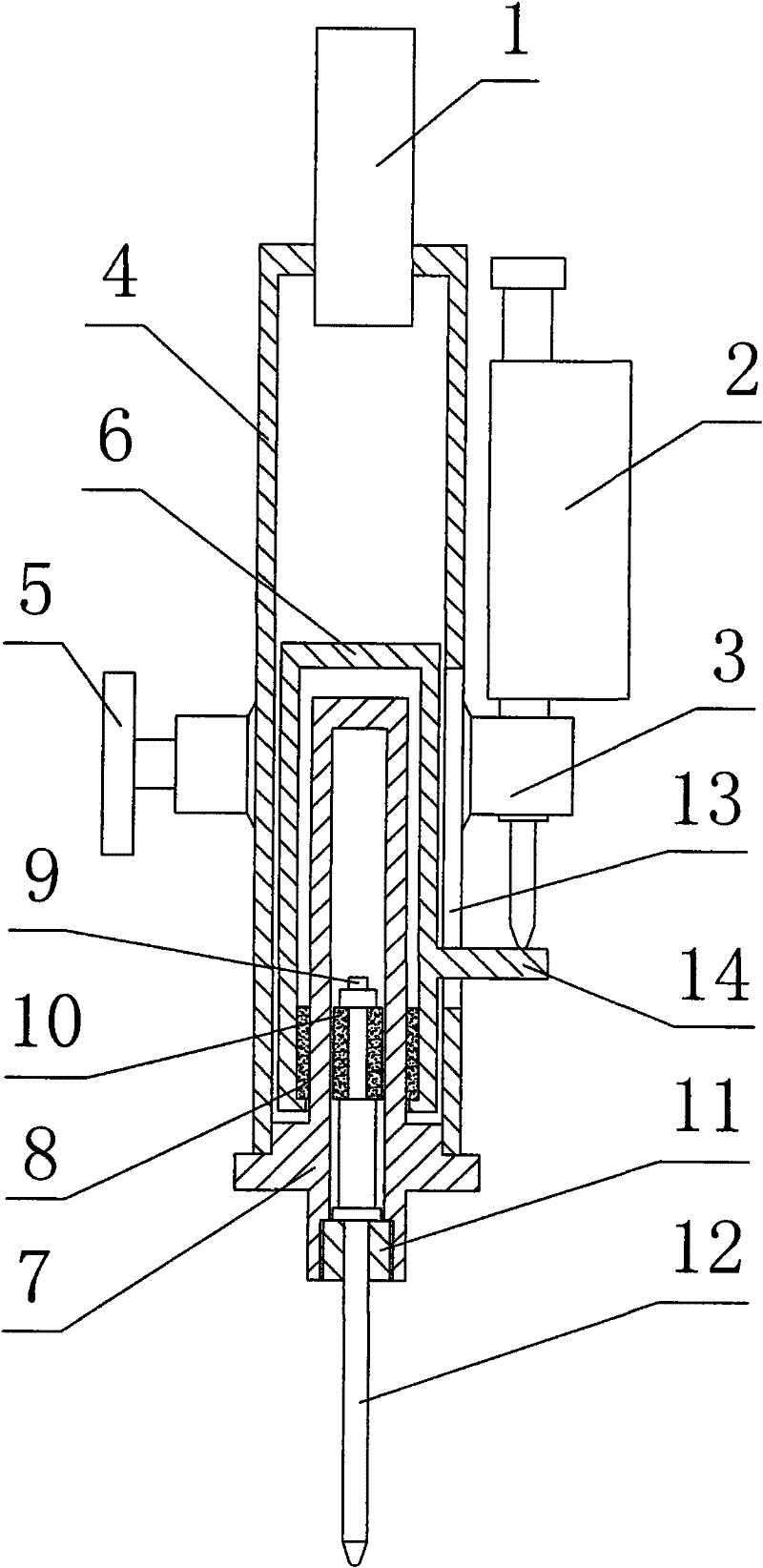

[0010] The high temperature and high pressure small length measuring device consists of a sensor 1, a dial indicator 2, a dial indicator bracket 3, a jacket 4, a compression screw 5, a movable sleeve 6, a device body 7, a high temperature magnet 8, 10, and compression nuts 9, 11 , And measuring rod 12 constitutes. Measuring rod 12 is housed in the center hole of device body 7, and measuring rod 12 is fixed by the compression nut 11 of the center hole lower end of device body 7, and the upper end of measuring rod 12 is fixed with a high temperature magnet 10 by compression nut 9. The outer cover of the device body 7 is equipped with a movable sleeve 6, and the inner wall of the movable sleeve 6 is equipped with a high-temperature magnet 8 corresponding to the high-temperature magnet 10 on the measuring rod 12. The high-temperature magnet 10 corresponds to the installation position of the high-temperature magnet 8. There is a jacket 4 on the outside, and a chute 13 is opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com