Double-ball pin cup steering linkage

A steering tie rod and ball pin seat technology, applied in the field of auto parts, can solve the problems of ball seat wear, product failure, ball head loose and abnormal noise, etc., and achieve the effect of improving product life, ensuring stability and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

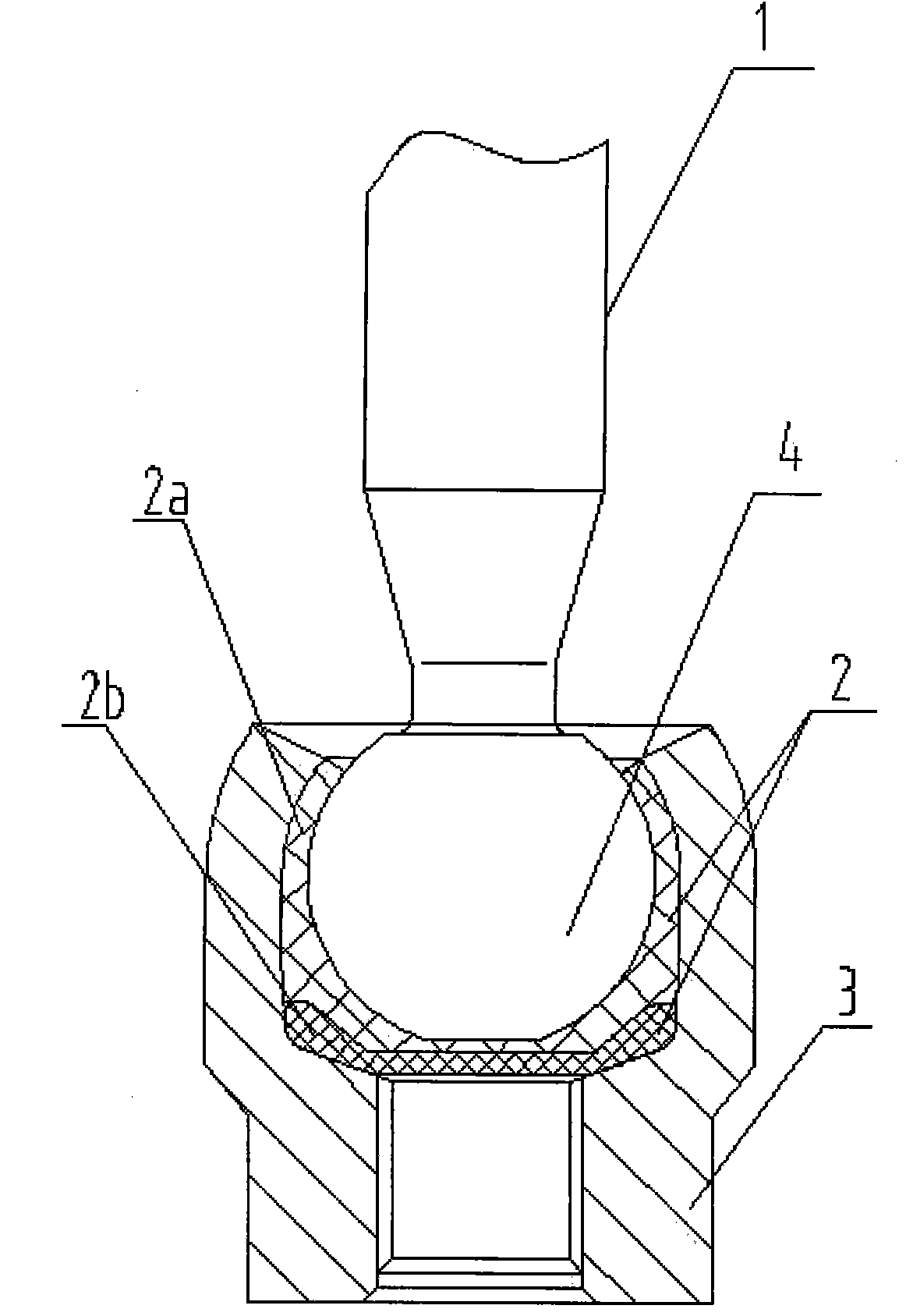

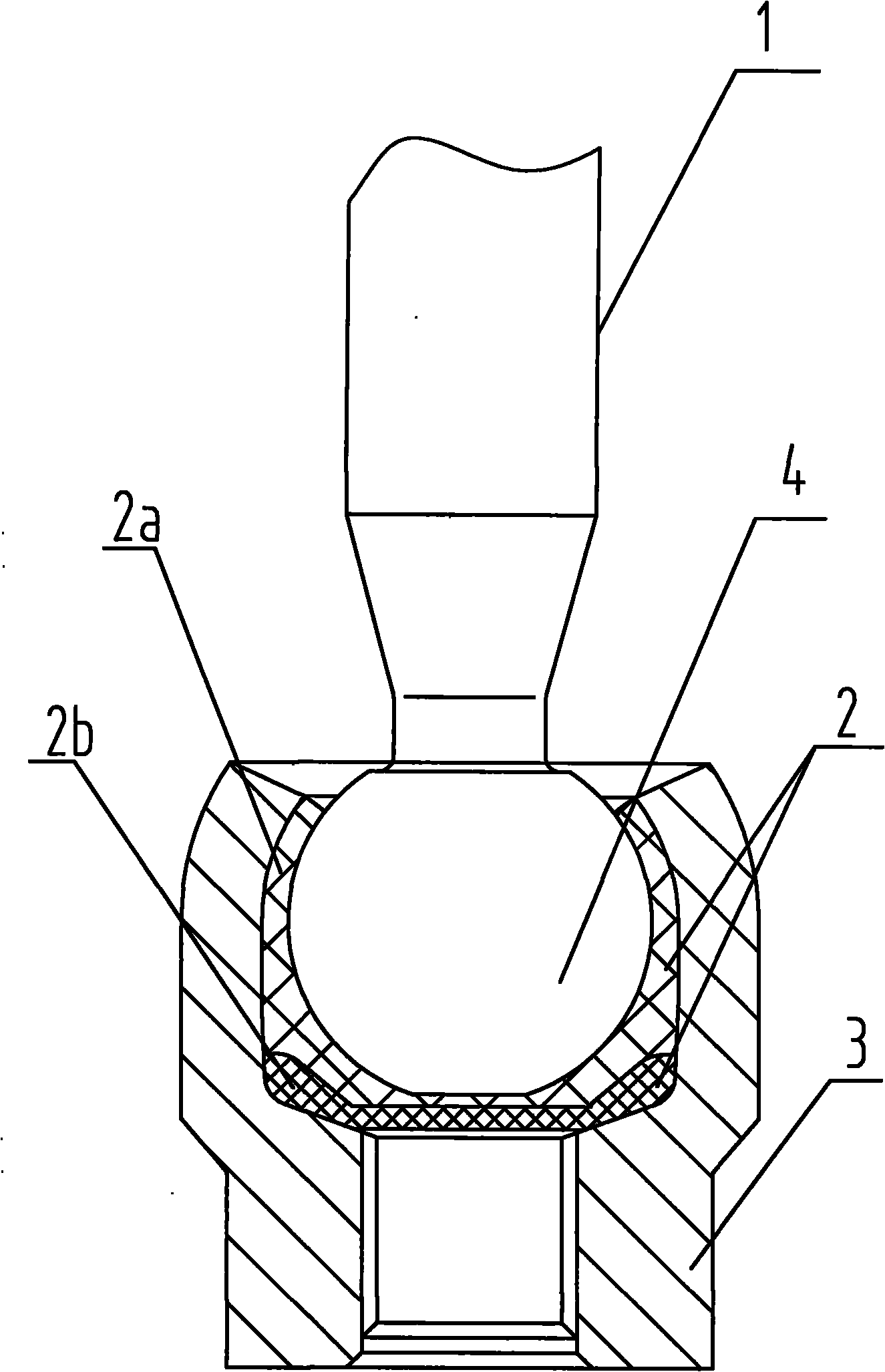

[0010] Such as figure 1 Shown: a steering tie rod with a double ball pin seat, including a steering tie rod, a ball seat and a ball seat cover, the steering tie rod has a ball head, the ball seat is arranged in the ball seat cover, and the ball seat has A spherical cavity, the ball head is placed in the spherical cavity of the ball seat, the ball seat is composed of an upper ball seat with a spherical cavity and a lower ball seat, wherein the upper ball seat with a spherical cavity and the ball The head forms a clearance fit, the lower ball seat is made of elastic plastic and the lower ball seat is compressed and arranged in the ball seat sleeve by the upper ball seat. The upper ball seat can be made of plastic materials with good wear resistance: such as polyoxymethylene, polyester, polycarbonate, polyamide, etc.; while the lower ball seat is made of plastic materials with better elasticity: such as polyethylene, polyamide, etc. Vinyl chloride, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com