Concrete shear wall

A technology of concrete shear wall and shear wall, applied in the direction of wall, formwork/formwork/work frame, structural elements, etc., can solve the problems of increasing cracks, the distance between shear walls cannot be too large, and the plane layout is inflexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment.

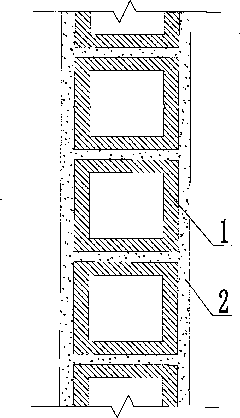

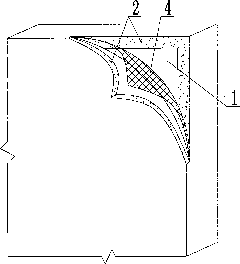

[0033] The embodiment of the present invention, the concrete shear wall, is characterized in that at least one module 1 is arranged in the shear wall, and self-compacting concrete 2 is poured outside the module 1, and the thickness of the self-compacting concrete 2 on both sides of the module 1 is less than or equal to 45mm . figure 1 It is the schematic diagram of the concrete shear wall section structure of embodiment 1 of the present invention, as figure 1 As shown, a plurality of modules 1 are arranged at intervals. The modules 1 are hollow modules with hard walls. Self-compacting concrete 2 is poured between the modules 1 and on both sides of the modules 1. The thickness of the self-compacting concrete is less than 45mm.

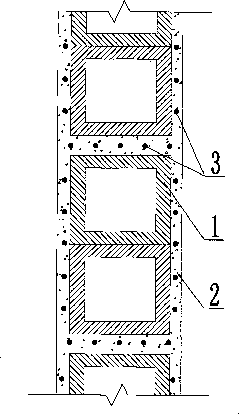

[0034] The present invention also lies in that said module 1 is a hollow or solid module. figure 2 It is the schematic diagram of the concrete shear wall s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com