Method for preparing anti-UV fabric by in-situ method

An anti-ultraviolet, in-situ method, applied to plant fibers, textiles, papermaking, fiber types, etc., can solve problems such as accelerated nanoparticle agglomeration, performance impact, and difficulty in achieving large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

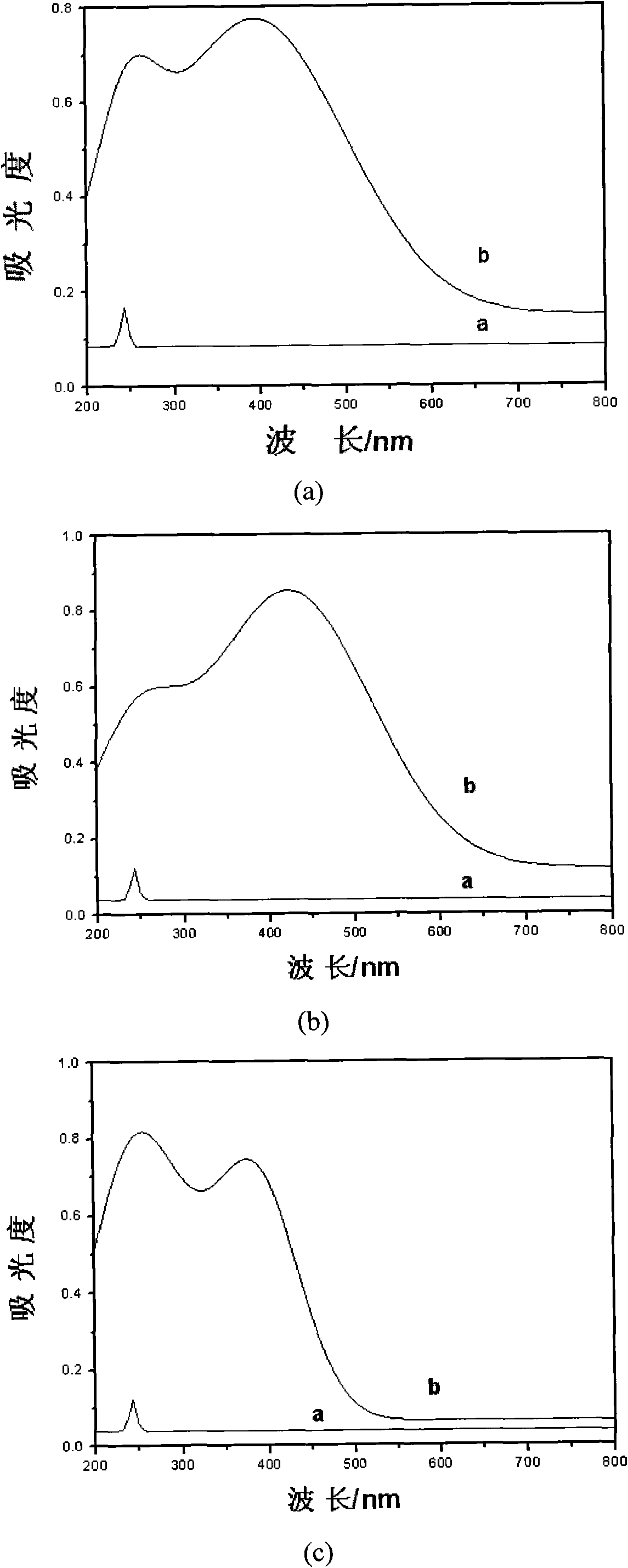

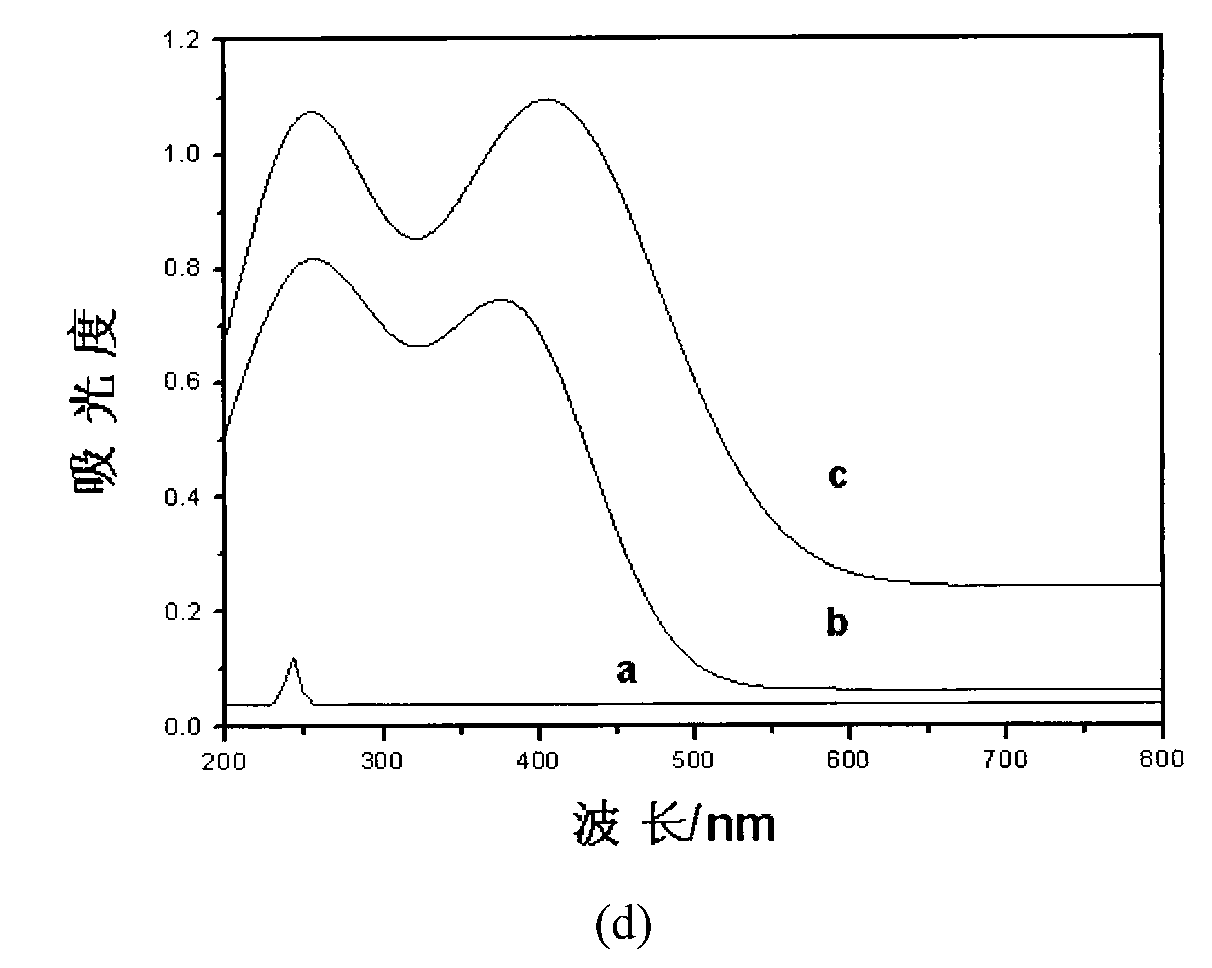

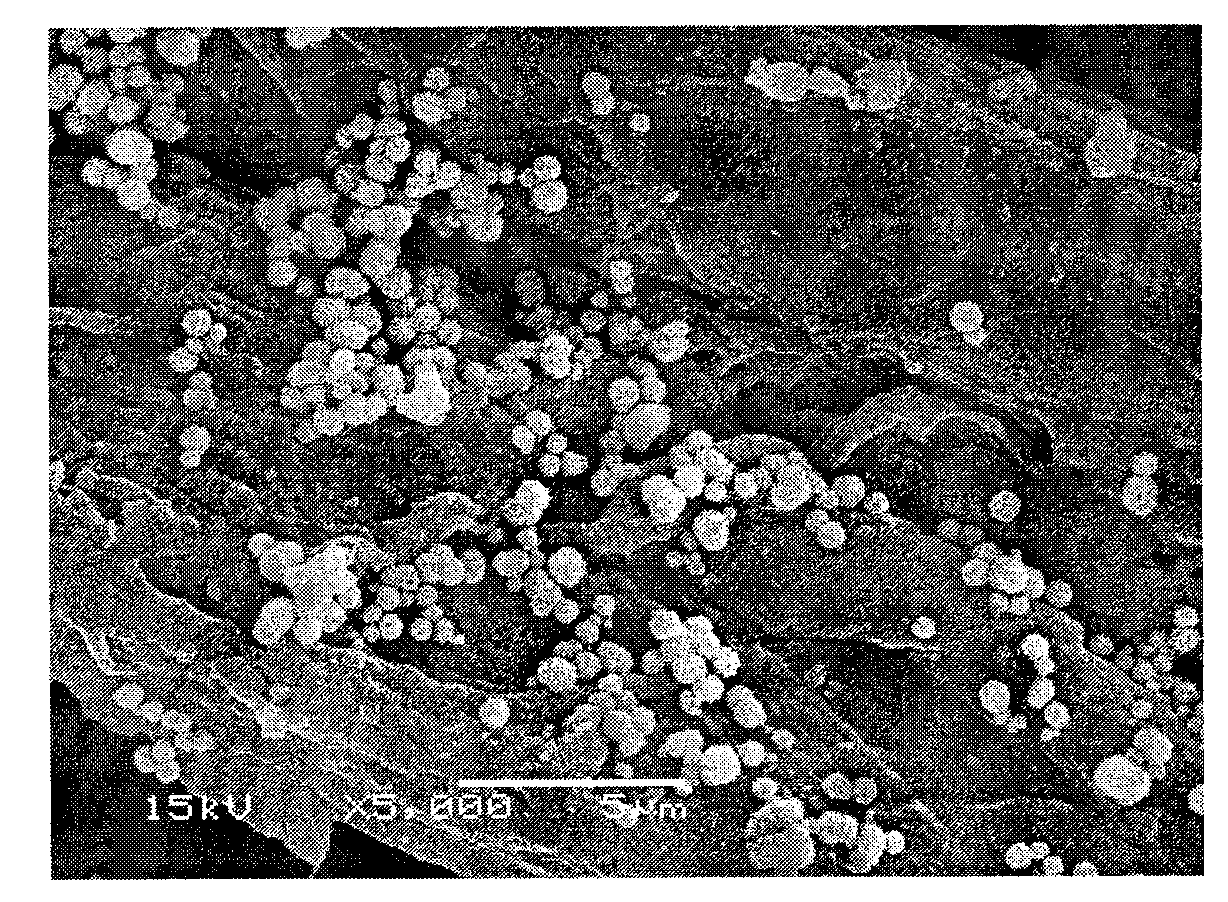

[0035] 1) Weigh 15g Ce(NO 3 ) 3 ·6H 2 O, dissolved in 4L water, stirred and dissolved evenly, and made into a solution;

[0036] 2) Add cetyltrimethylammonium bromide, ammonia water, and hydrogen peroxide into the solution in turn, stir evenly, put the cotton fabric in the solution, soak for 40 minutes, take out the fabric, and dry at 120 degrees for 3 minutes

[0037] In the above preparation method, Ce(NO 3 ) 3 ·6H 2 O, cetyltrimethylammonium bromide, ammonia water and hydrogen peroxide mass ratio: 10:10:7:3.

[0038] Place the dried cotton cloth strips in a UV spectrophotometer for UV testing.

[0039] Absorbance A=lg(I 0 / I)=-lgT, I 0 I is the intensity of the incident light, I is the intensity of the transmitted light, and T is the transmittance.

Embodiment 2

[0041] 1) Weigh 20g Ce(NO 3 ) 3 ·6H 2 O, dissolved in 5L of water, stirred and dissolved evenly, and made into a solution;

[0042] 2) Add cetyltrimethylammonium bromide, ammonia water, and hydrogen peroxide into the solution in turn, stir evenly, put the cotton fabric in the solution, soak for 15 minutes, take out the fabric, and dry at 140 degrees for 2 minutes

[0043] In the above preparation method, Ce(NO 3 ) 3 ·6H 2 O, cetyltrimethylammonium bromide, ammonia and hydrogen peroxide

[0044] Mass ratio: 10:15:3:2.

[0045] Place the dried cotton cloth strips in a UV spectrophotometer for UV testing.

[0046] Absorbance A=lg(I 0 / I)=-lgT, I 0 I is the intensity of the incident light, I is the intensity of the transmitted light, and T is the transmittance.

Embodiment 3

[0048] 1) Weigh 25g Ce(NO 3 ) 3 ·6H 2 O, dissolved in 6L water, stirred and dissolved evenly, and made into a solution;

[0049] 2) Add sodium dodecylbenzenesulfonate, ammonia water, and hydrogen peroxide into the solution in turn, stir evenly, put the cotton fabric in the solution, soak for 20 minutes, take out the fabric, and dry it at 170 degrees for 2 minutes

[0050] In the above preparation method, Ce(NO 3 )_ 3 ·6H 2 O, sodium dodecylbenzenesulfonate, ammonia water and hydrogen peroxide mass ratio: 10:22:3:5.

[0051] Place the dried cotton cloth strips in a UV spectrophotometer for UV testing.

[0052] Absorbance A=lg(I 0 / I)=-lgT, I 0 I is the intensity of the incident light, I is the intensity of the transmitted light, and T is the transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com