Method for recovering silver from lead-separating liquid of silver-separating residue of copper anode slime

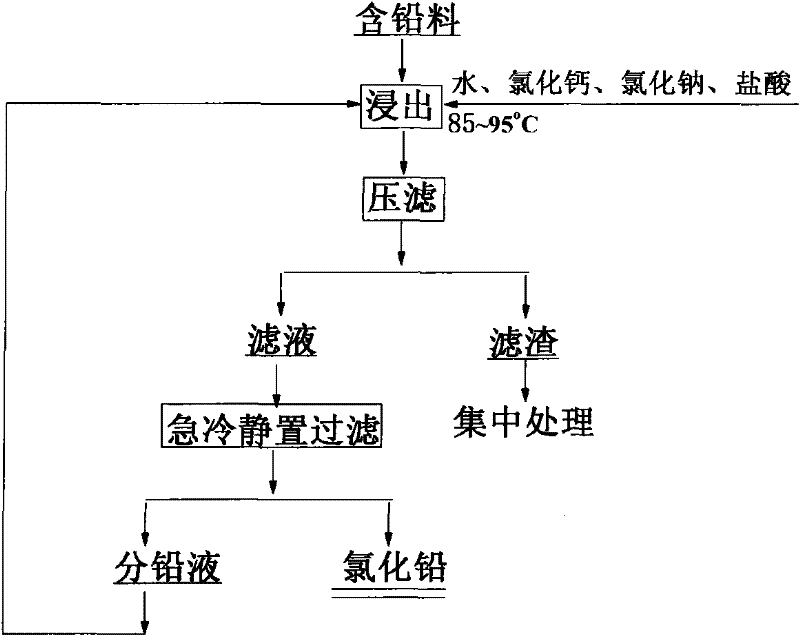

A technology for copper anode slime and silver separation slag is applied in the direction of improving process efficiency, which can solve problems such as short processing process flow and achieve the effect of simple and easy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

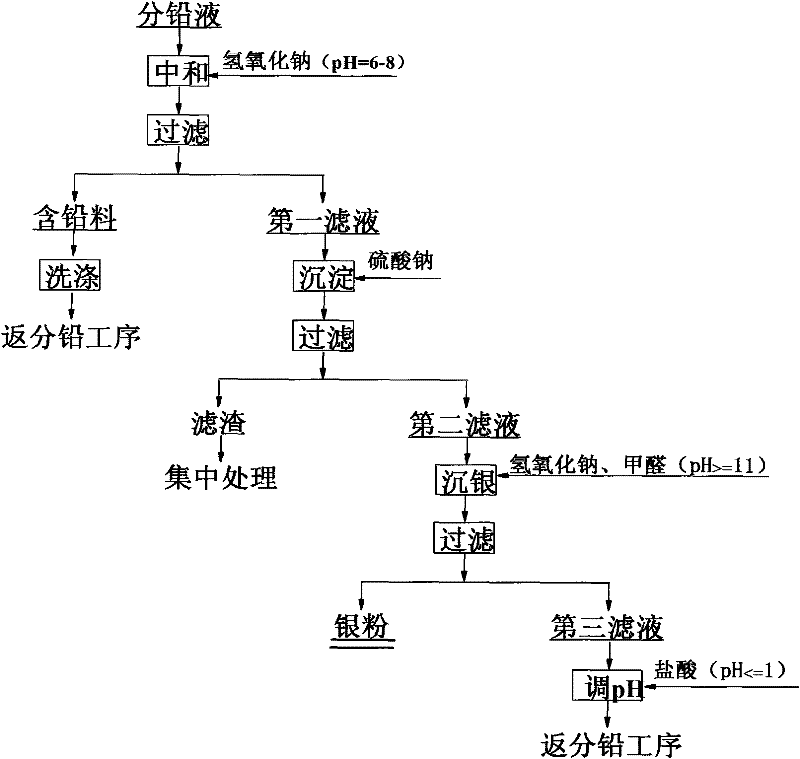

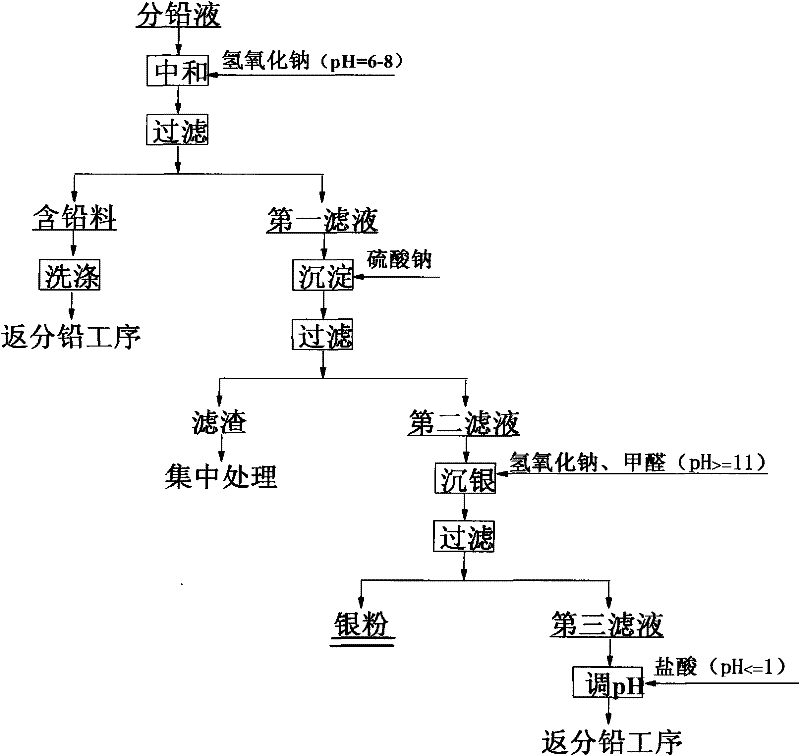

Method used

Image

Examples

Embodiment 1

[0015] Put 1L of lead liquid (silver content 2.1g / L) into the stirring tank, add sodium hydroxide for neutralization, adjust the pH of the lead liquid to 6, lead will precipitate in the form of lead hydroxide, filter to obtain lead Feed and the first filtrate, the lead-containing material is washed and returned to the lead separation process for lead separation; the first filtrate is added with sodium sulfate, until the solution does not produce precipitation, stop adding sodium sulfate, filter, obtain the filter residue and the second filtrate, and concentrate the filter residue; Sodium oxide adjusted the pH of the second filtrate to 12, added 0.7g of formaldehyde, stirred for 10 minutes, filtered to obtain silver powder and the third filtrate, added hydrochloric acid to the third filtrate to adjust the pH to 0.5, and returned to the lead separation process. The silver recovery rate is 98.5%.

Embodiment 2

[0017] Put 1L of lead liquid (silver content 1.8g / L) into the stirring tank, add sodium hydroxide for neutralization, adjust the pH of the lead liquid to 7.5, lead will precipitate in the form of lead hydroxide, filter to obtain lead Feed and the first filtrate, the lead-containing material is washed and returned to the lead separation process for lead separation; the first filtrate is added with sodium sulfate, until the solution does not produce precipitation, stop adding sodium sulfate, filter, obtain the filter residue and the second filtrate, and concentrate the filter residue; Sodium oxide adjusted the pH of the second filtrate to 11.5, added 0.9g of formaldehyde, stirred for 15 minutes, filtered to obtain silver powder and the third filtrate, added hydrochloric acid to the third filtrate to adjust the pH to 0.8, and returned to the lead separation process. The silver recovery rate is 99.1%.

Embodiment 3

[0019] Put 1L of lead liquid (silver content 1.5g / L) into the stirring tank, add sodium hydroxide for neutralization, adjust the pH of the lead liquid to 8, lead will precipitate in the form of lead hydroxide, filter to obtain lead Feed and the first filtrate, the lead-containing material is washed and returned to the lead separation process for lead separation; the first filtrate is added with sodium sulfate, until the solution does not produce precipitation, stop adding sodium sulfate, filter, obtain the filter residue and the second filtrate, and concentrate the filter residue; Sodium oxide adjusted the pH of the second filtrate to 13, added 1.2g of formaldehyde, stirred for 30 minutes, filtered to obtain silver powder and the third filtrate, added hydrochloric acid to the third filtrate to adjust the pH to 0.2, and returned to the lead separation process. The silver recovery rate is 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com