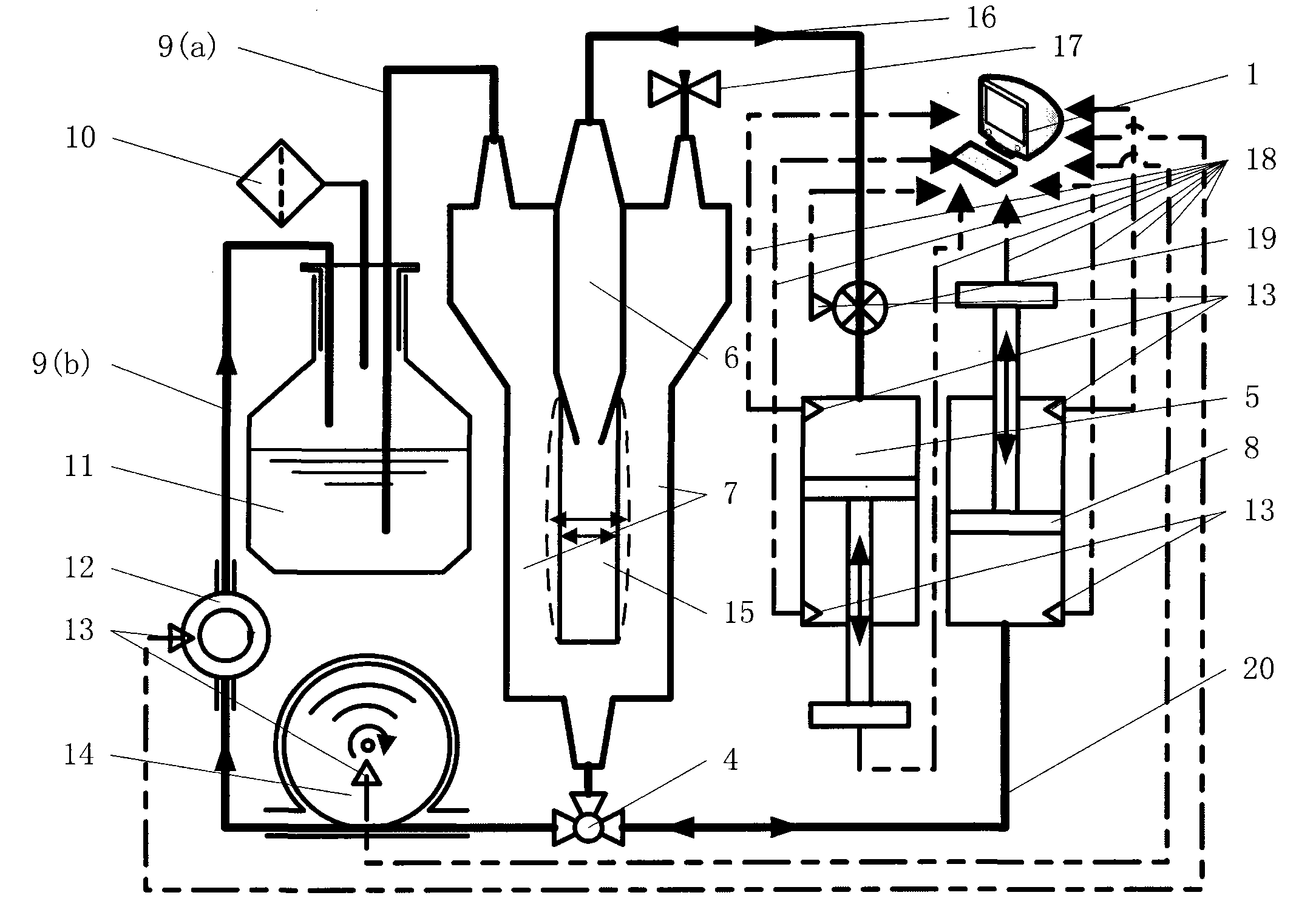

Tissue engineering myocardium bioreactor constructed by pouring, perfusion and pulsation combination

A technology of bioreactor and tissue engineering, applied in the direction of specific-purpose bioreactor/fermenter, biochemical instrument, biochemical equipment and method, etc., can solve the problem of ambiguous relationship between mechanism design, failure to maintain and repeated use, Cardiomyocytes are difficult to establish connections, etc., to achieve the effect of increasing cell planting density, strengthening exchange, and promoting directional connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Construction of tubular tissue-engineered myocardium

[0054] Liquid collagen (1%) is mixed with chitosan (1% acetic acid solution) to obtain a tissue engineering scaffold material, and a pipe-shaped mold is used to solidify at a low temperature and freeze-dried for 24 hours to obtain a pipe-shaped scaffold. The scaffold was cross-linked with sodium polyphosphate and adjusted to be neutral, rinsed with PBS and dried for later use. Install the bracket on the pulsation effect hose, and then install and shape the bioreactor as a whole. The newly isolated mouse cardiomyocytes were dispersed in the culture medium to obtain a cell suspension, and the concentration of the suspension was 10 6 cells / mL. At 4°C, 1ml of the cell suspension was mixed with 1ml of 10% Metrigel solution, and the mixed solution was added into the perfusion chamber, and after the liquid inlet was closed, the cells were perfused for 20 minutes. Cells were cultured statically after perfusion...

Embodiment 2

[0055] Example 2: Construction of Strip-shaped Tissue-Engineered Myocardium Patch

[0056] Mix according to the method in Example 1 to obtain collagen-chitosan tissue engineering scaffold material, use a strip-shaped mold, freeze-dry for 24 hours after solidifying at a low temperature to obtain a strip-shaped scaffold. The scaffold was cross-linked with sodium polyphosphate and adjusted to be neutral, rinsed with PBS and dried for later use. Wrap the support around the pulsation effect hose along the length direction, and then install and shape the bioreactor as a whole. The newly isolated mouse cardiomyocytes were dispersed in the culture medium to obtain a cell suspension, and the concentration of the suspension was 10 6 cells / mL. At 4°C, 1ml of the cell suspension was mixed with 1ml of 10% Metrigel solution, and the mixed solution was added into the perfusion chamber, and after the liquid inlet was closed, the cells were perfused for 20 minutes. Cells were cultured stati...

Embodiment 3

[0057] Example 3: Effect of cell perfusion on the construction of tissue engineered myocardial patch

[0058] Mix according to the method in Example 1 to obtain collagen-chitosan tissue engineering scaffold material, and prepare a pipeline-shaped scaffold. The scaffold was cross-linked with sodium polyphosphate and adjusted to be neutral, rinsed with PBS and dried for later use. Install the bracket on the pulsation effect hose, and then install and shape the bioreactor as a whole. The newly isolated mouse cardiomyocytes were dispersed in the culture medium to obtain a cell suspension, and the concentration of the suspension was 10 6 cells / mL. At 4°C, 1ml of the cell suspension was mixed with 1ml of 10% Metrigel solution, and the mixed solution was added into the perfusion chamber, and after the liquid inlet was closed, the cells were perfused for 20 minutes. Then carry out static culture, and replace the culture medium every 24 hours. After culturing for 3 days, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com