Carrot seeding and film laminating machine

A mulching machine, carrot technology, applied in sowing, climate change adaptation, plant protection cover, etc., can solve the problem of single function of seeder, save manpower and material resources, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

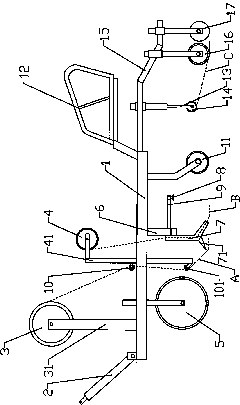

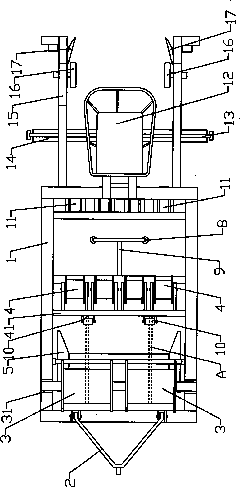

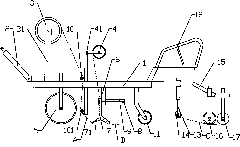

[0025] Examples such as figure 1 , figure 2 As shown, a carrot seeding and laminating machine includes a main frame 1, and a traction frame 2 is provided at the front end of the main frame 1. When working, it can be towed by a tractor and other power machinery, which saves manpower and improves production efficiency. A front traveling wheel 5 is provided below the front end of the main frame 1.

[0026] The main frame 1 is provided with a drip tape laying device and a seed tape laying device. The drip tape laying device includes a drip tape holder 31 installed on the main frame 1, and the upper ends of the drip tape holder 31 are respectively installed with drip tape rollers 3, A drip tape A is wound on the drip tape roller 3.

[0027] The seed belt laying device includes four seed belt roller supports 41 installed on the main frame 1. The upper ends of the seed belt roller supports 41 are respectively installed with seed belt rollers 4, and the seed belt roller 4 is wrapped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com