Method and device for cleaning the outer surface of roll or roller

A technology for cleaning devices and outer surfaces, which is applied in the direction of length measuring devices, measuring devices, and keeping roll equipment in an effective state, and can solve problems such as inability to clean, polishing tools and high wear of rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

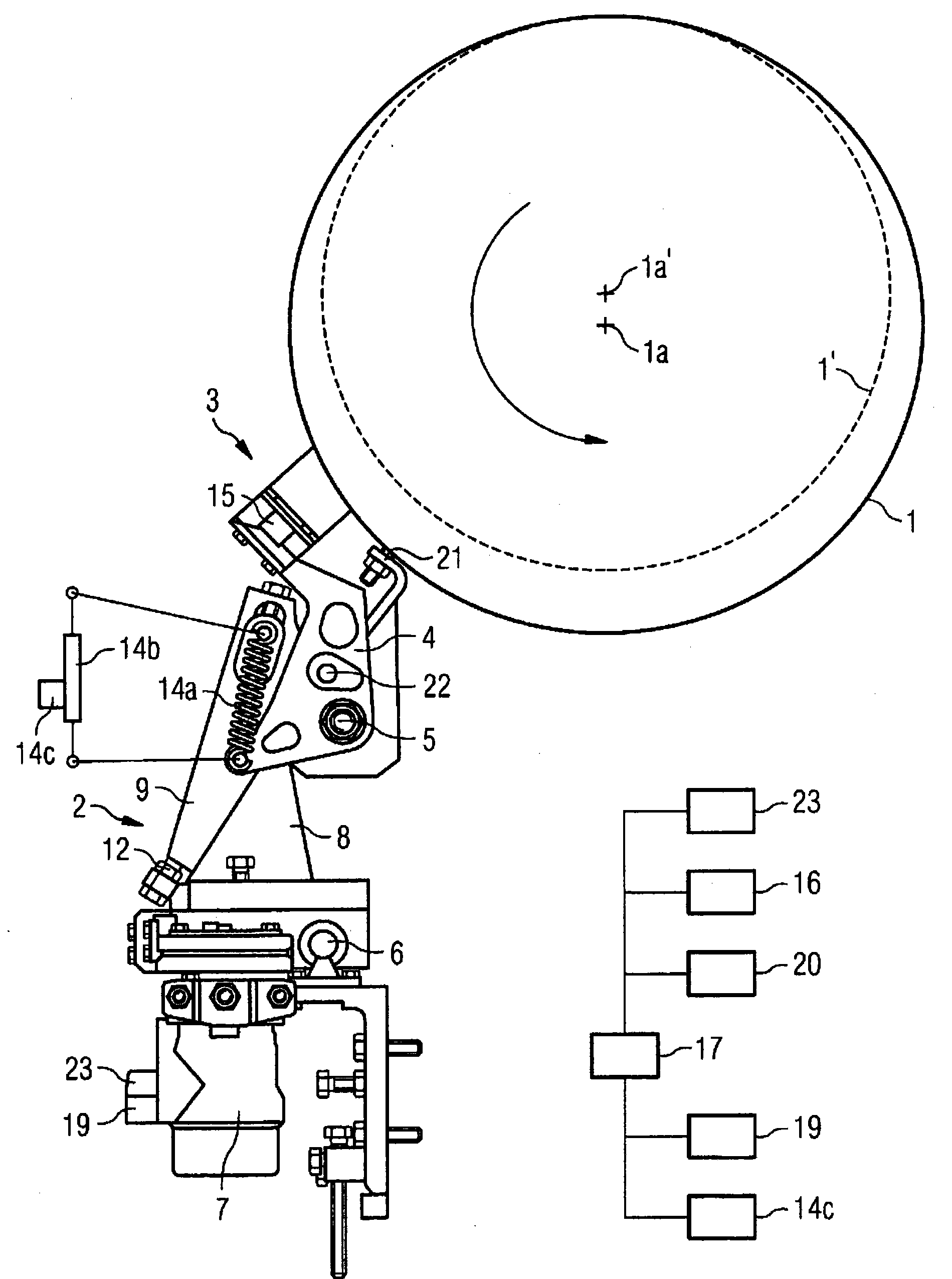

[0044] figure 1 and 2 The construction of a cleaning device for drive rollers according to the invention is shown schematically by way of example, showing how the cleaning device is installed in a strip production plant and a strip processing plant which are not shown in detail here.

[0045] exist figure 1 The operative position of the cleaning device resting on the outer surface of the drum 1 rotating about the axis of rotation 1 a in the direction of the arrow is shown in . The dashed line indicates the diameter of a smaller roller 1' rotating around the axis of rotation 1a, on which the cleaning device can likewise rest.

[0046] The cleaning device comprises a conveyor slide 2 , a cleaning tool 3 made of a polishing stone, and a carrier element 4 for the cleaning tool, wherein the carrier element 4 is mounted pivotably on the conveyor slide 2 via a pivot pin 5 . The conveyor slide 2 is supported and guided on a guide 6 which extends parallel to the axis of rotation 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com