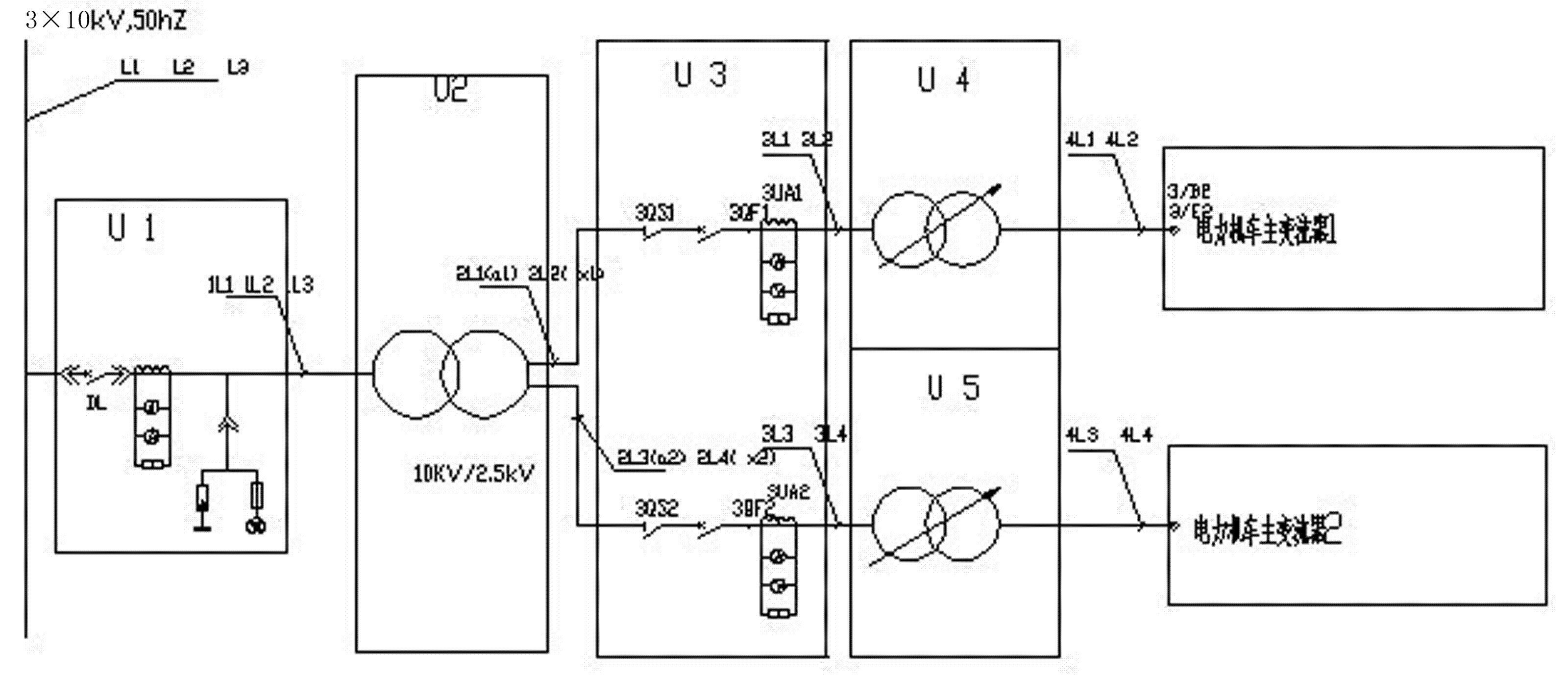

Adjustable high voltage power supply for routine test station of main converter cabinet of locomotive

A routine test, high-voltage power supply technology, applied in the direction of conversion equipment that can be converted to DC without intermediate conversion, to achieve the effect of solving harmonic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

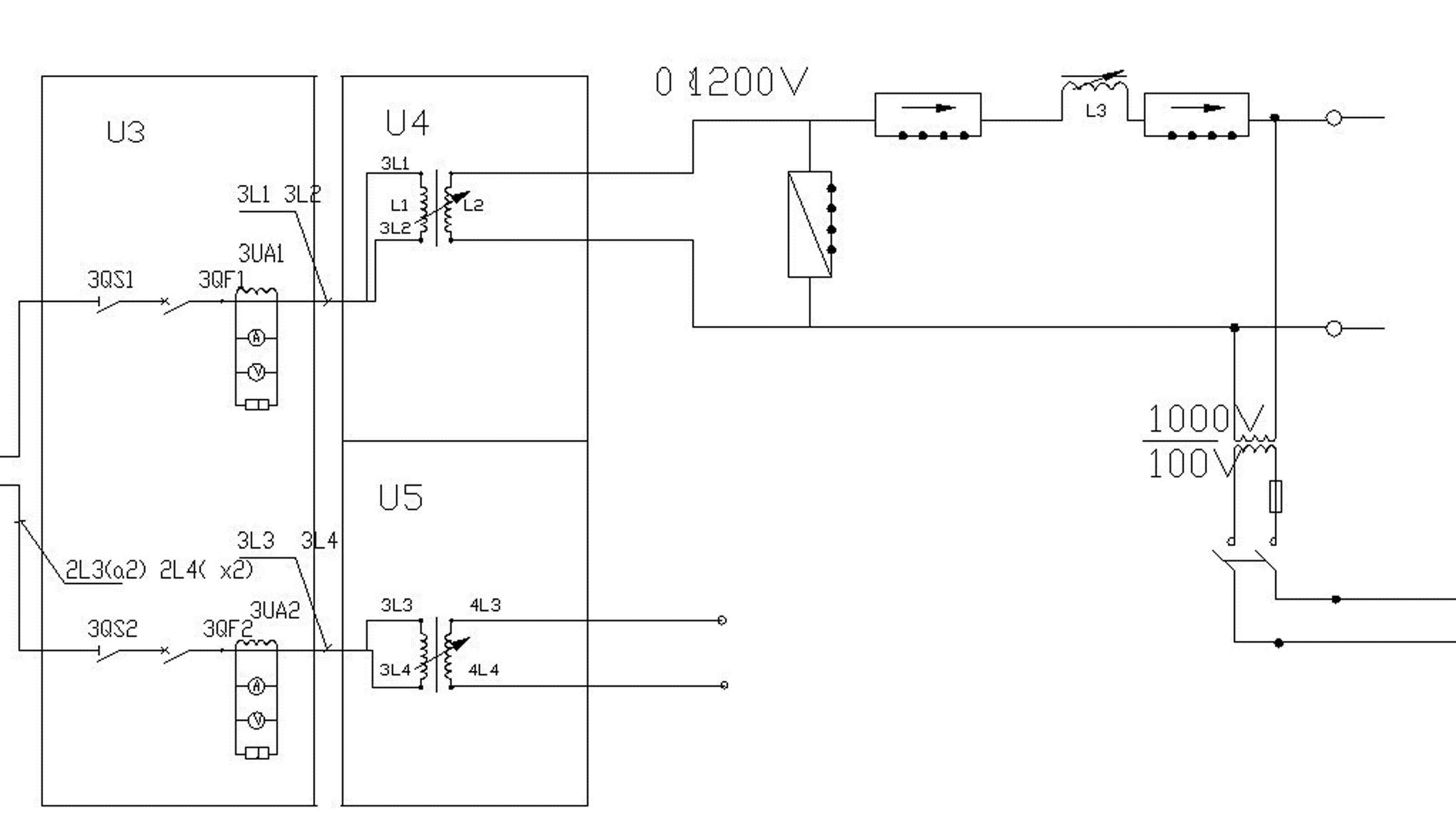

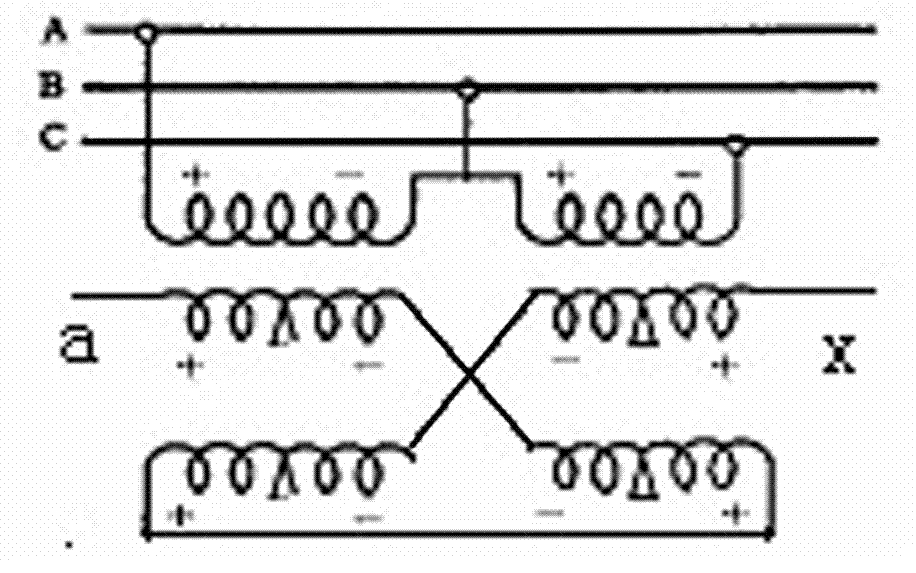

[0011] Adjustable high-voltage power supply for the routine test station of the locomotive main converter cabinet, including a three-phase-to-single-phase special transformer U2 and two independently working single-phase adjustable outputs driven by the three-phase to single-phase special transformer The non-contact induction voltage regulator U4, U5, the three-phase to single-phase special transformer U2 has two windings on the primary side, four windings on the secondary side, and two of the four windings on the secondary side are the same as the original One winding of the secondary side is induced (set on the same core column), the other two windings of the secondary side are induced with the other winding of the primary side (that is, set on the same core column), and the end of one winding of the primary side is connected to the other The first ends of the windings are connected, the first end of one winding, the connection node between the two windings, and the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com