Pressure-compensated rotary joint

A rotary joint and pressure compensation technology, applied in the field of compensators, can solve problems such as unreliable sealing, and achieve the effects of avoiding leakage, compensating wear and eliminating stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

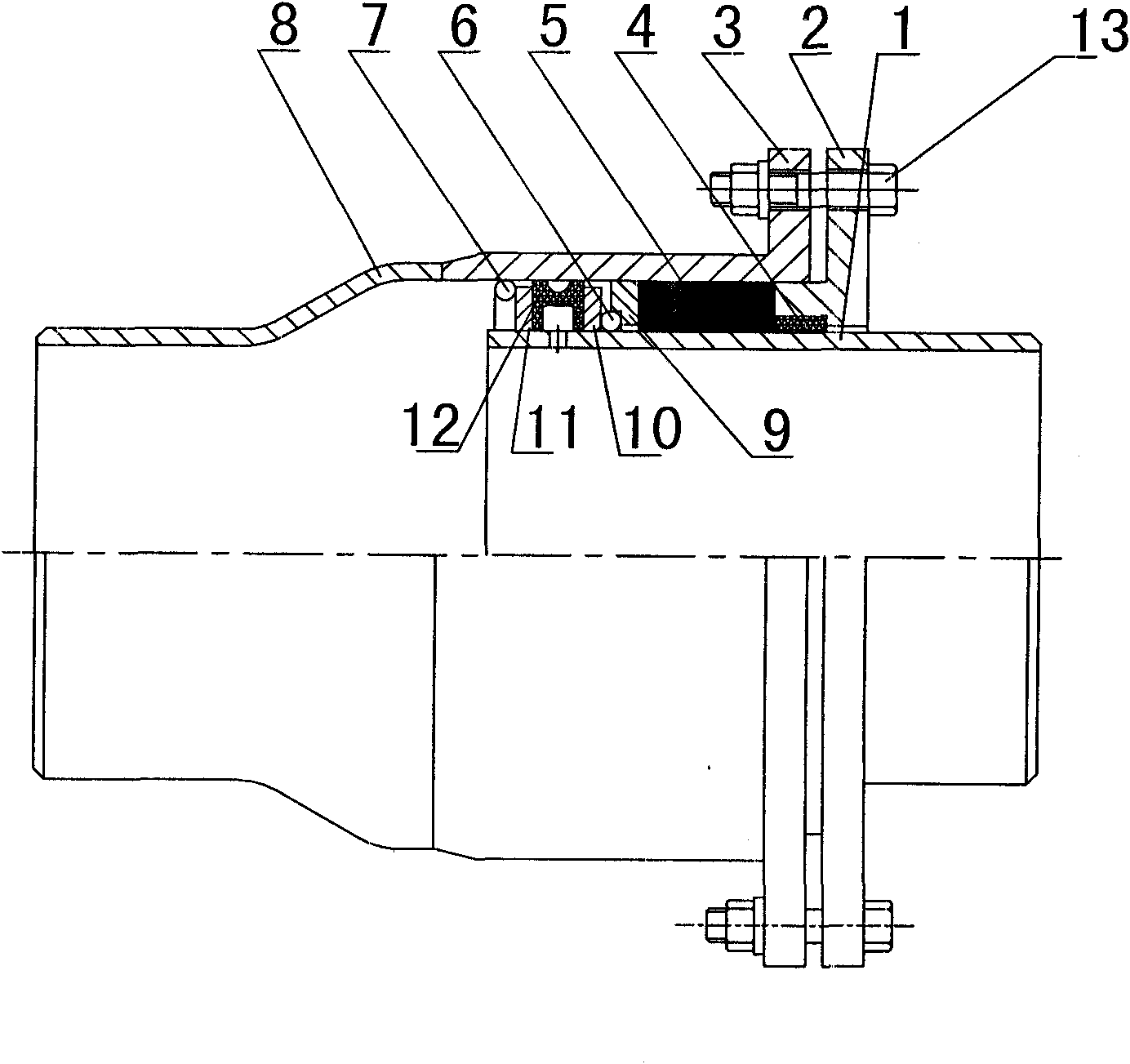

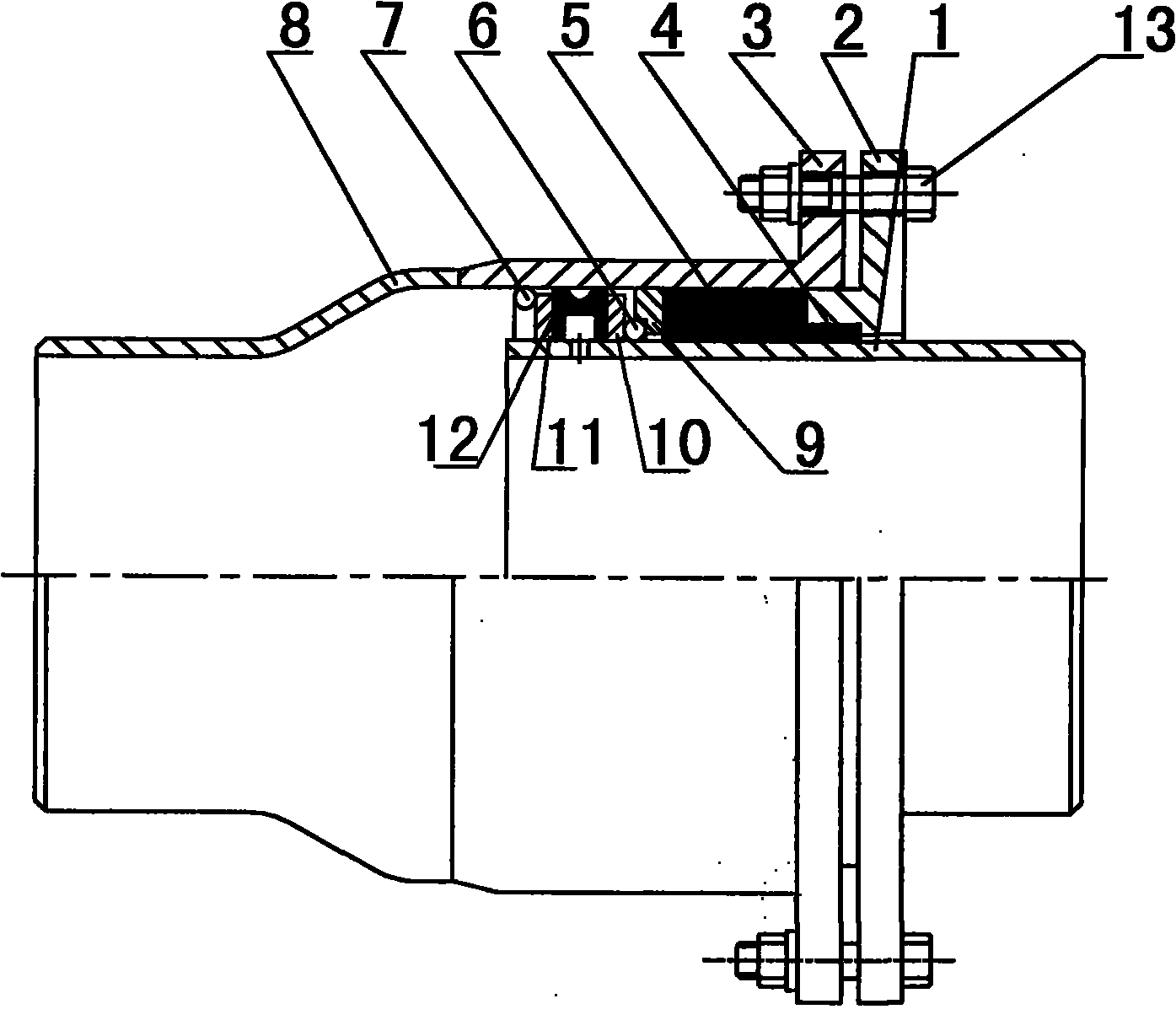

[0010] The pressure compensating rotary joint of this embodiment is as attached figure 1 As shown, it is mainly composed of an outer sleeve welded by a sleeve 3 and a reducer 8 , an inner tube 1 inserted into the sleeve 3 at one end, and a gland flange 2 sleeved outside the inner tube 1 . The sleeve 3 of the outer casing has an end flange, and the end flange is fixedly connected with the gland flange 2 through fastening bolts 13 . The thrust rings 7 and the connecting retaining rings 9 of circular sections distributed at intervals are fixedly installed in the inner hole of the insertion end of the sleeve 3 of the outer casing. The outer circumference of the insertion end of the inner tube 1 is fixed with a first retaining ring 11 and a second retaining ring 10 axially spaced apart, and there is a perforation on the pipe wall between the first retaining ring and the second retaining ring. The gland flange 2 has an extension ring extending into the outer casing sleeve 3 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com