Arc spiral cylindrical gear and arc rack

A cylindrical gear and helical wheel technology, which is applied in the field of arc racks, can solve the problems such as cannot be popularized and applied, and achieve the effect of tight and precise motion trajectory without gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

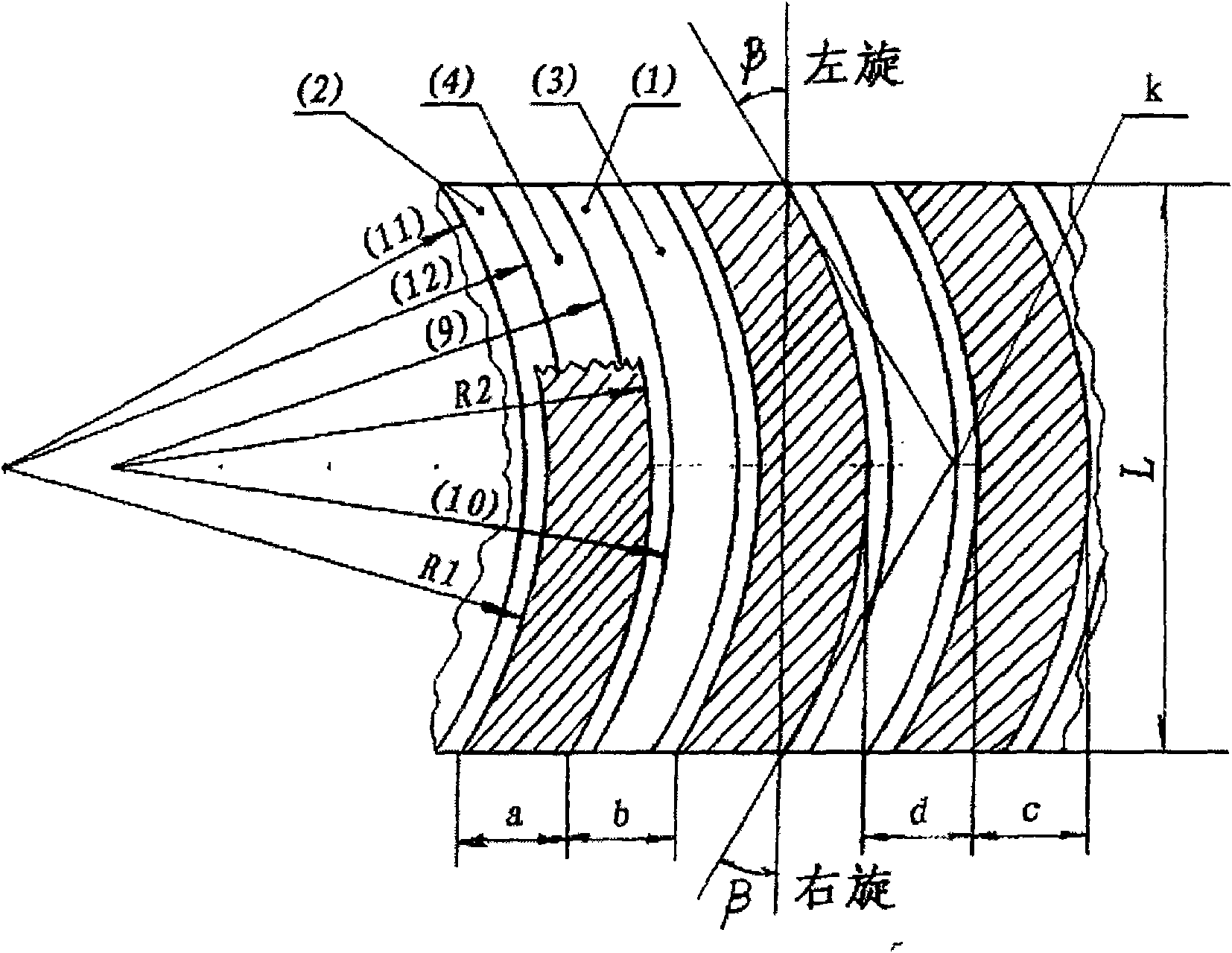

[0031] Aiming at the deficiencies of the prior art, the present invention overcomes the technical barrier of the ideal form of meshing, creates the system theory of "principle and manufacture of arc helical cylindrical gears", and demonstrates the basis of various parameters. The ratio relationship between R, L and m in the figure People call it "Wanyan Xueming Standard", which regulated the cutting tool standard, matched the process standard, invented "arc spiral cylindrical gear and arc rack" and various gear making machine tools, and expanded the scope of application.

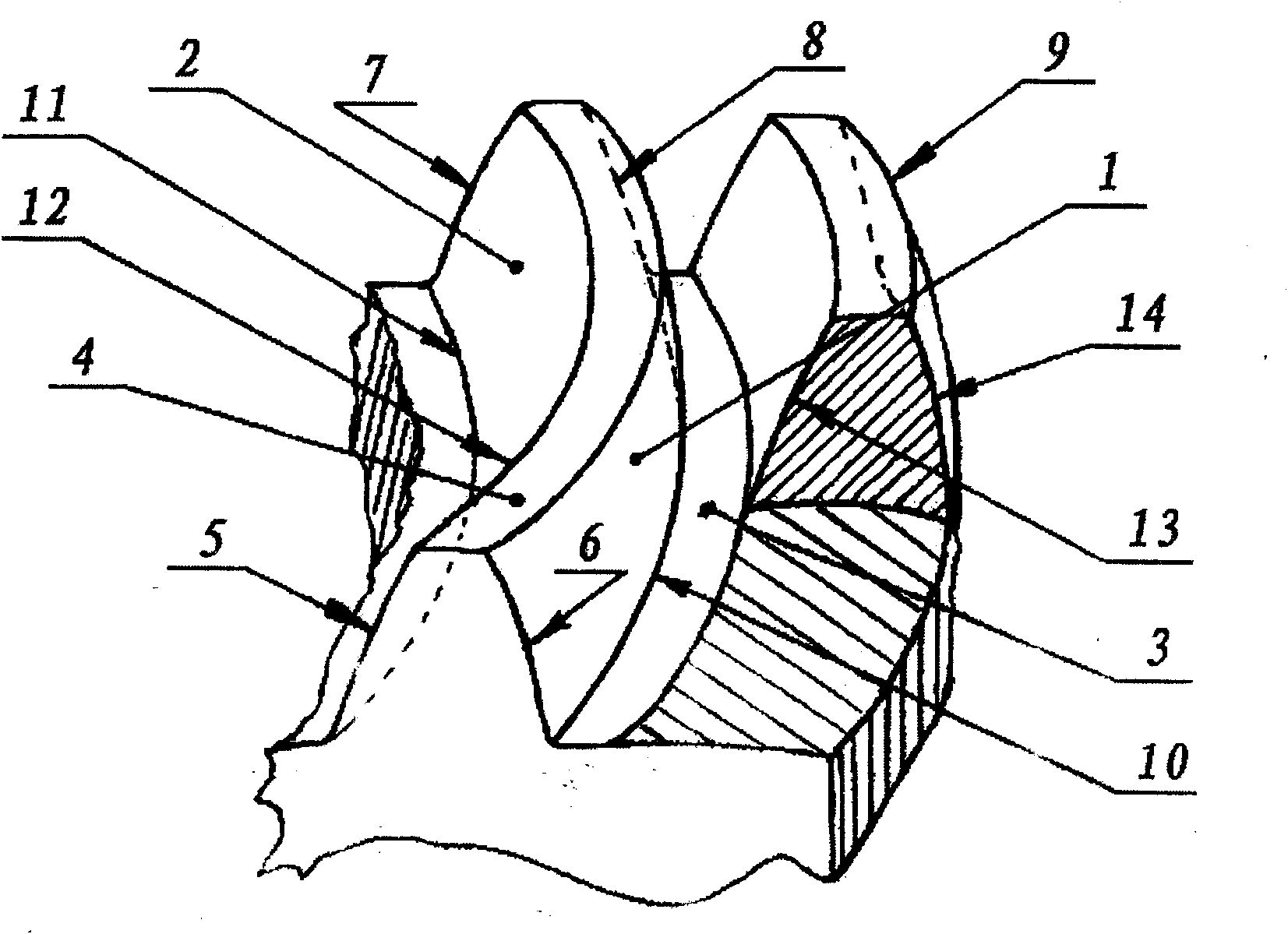

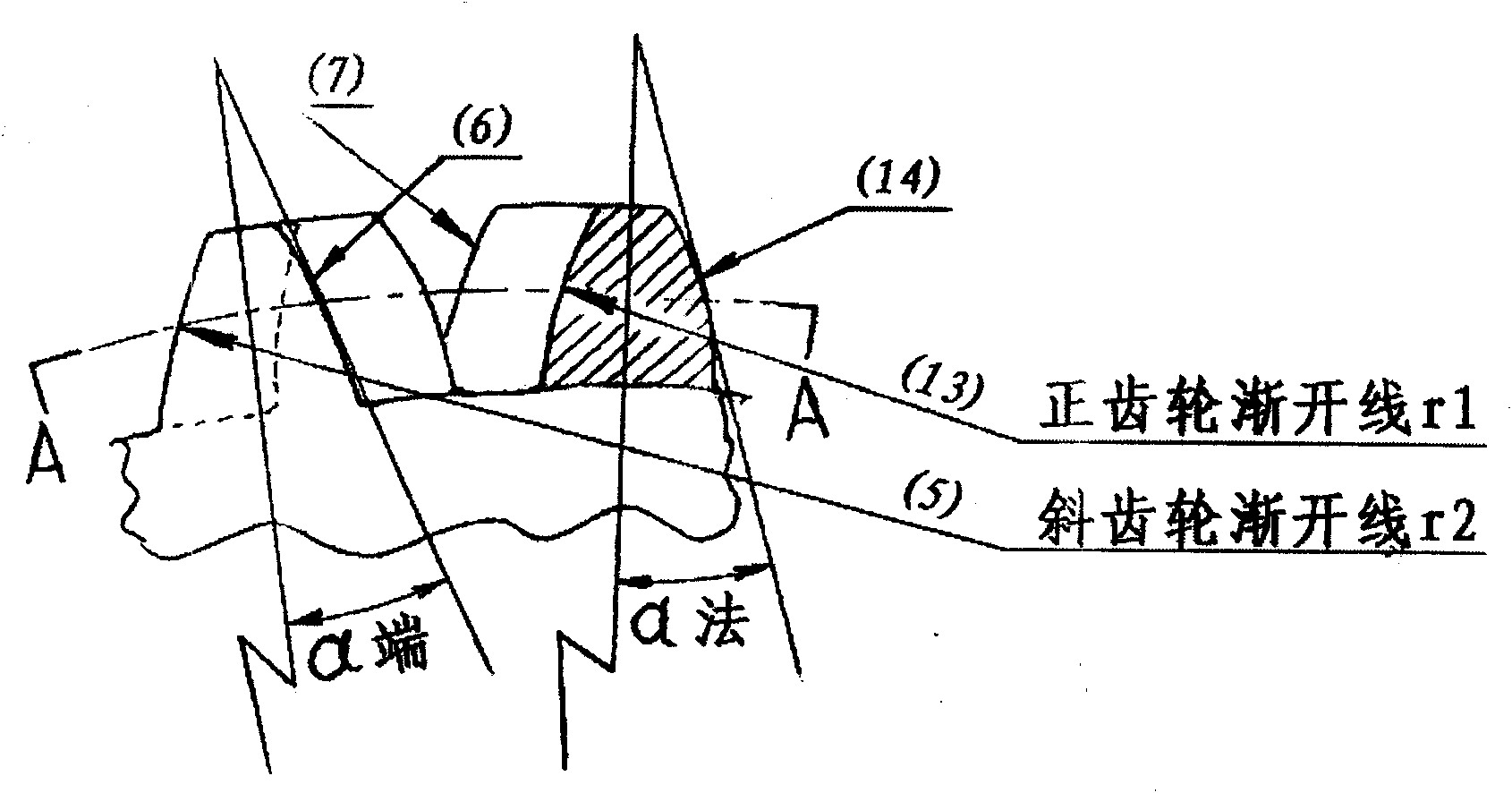

[0032] The main structure of the arc helical cylindrical gear of the present invention is as follows: figure 1 Shown: It consists of convex tooth surface 1, concave tooth surface 2, dedendum 3, and tooth top 4. The midpoint section contour lines 13 and 14 of the tooth length L are the involute tooth profile of the spur gear, and the section away from the midpoint becomes the involute tooth profile of the hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com