Corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance

An anti-fatigue and wear-resistant technology, applied in the field of high-performance corrosion-resistant heavy rail steel, can solve the problems of production cost, corrosion-resistant strength, fatigue performance, wear-resistant performance and welding performance, and achieve the effect of improving service performance and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

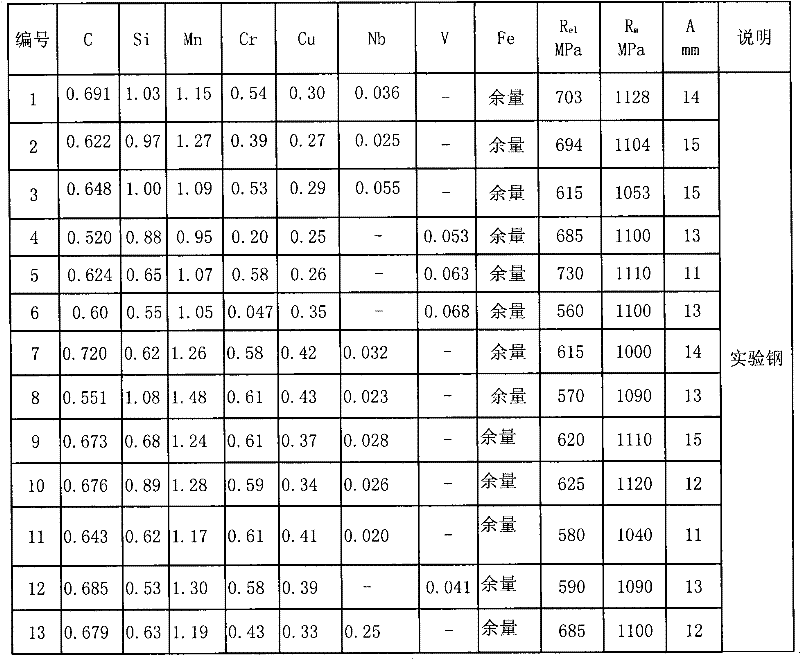

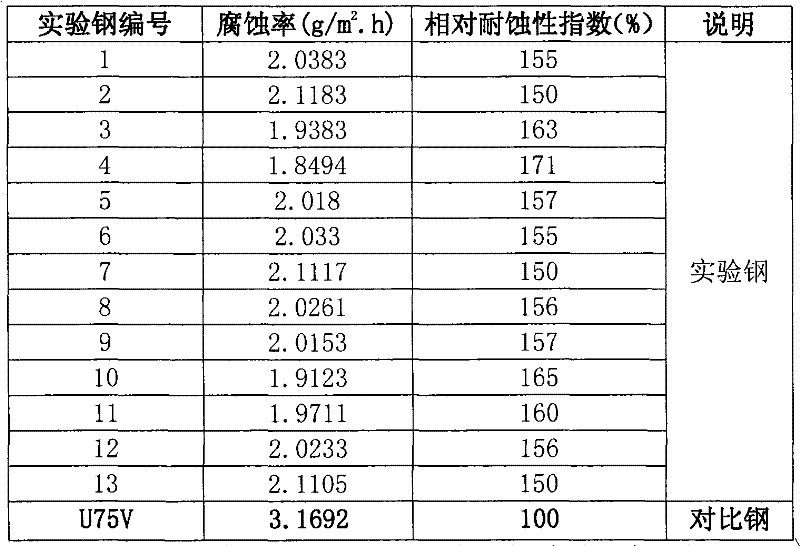

Examples

Embodiment 1

[0044] Embodiment 1: High-strength, high-toughness and corrosion-resistant air-cooled Sorbitite steel rail for railway, its basic composition is (weight percentage): C: 0.65, Si: 0.8, Mn: 1.10, Cu: 0.3, Nb: 0.03, Cr: 0.25, The rest is Fe.

Embodiment 2

[0045] Embodiment 2: High-strength, high-toughness, corrosion-resistant, air-cooled Sorbitite steel rail for railway, its basic composition is (weight percentage): C: 0.70, Si: 0.65, Mn: 1.4, Cu: 0.25, Nb: 0.023, Cr: 0.2, The rest is Fe.

Embodiment 3

[0046] Embodiment 3: High-strength, high-toughness, corrosion-resistant, air-cooled Sorbitite steel rail for railway, its basic composition is (weight percentage): C: 0.55, Si: 1.00, Mn: 1.0, Nb: 0.016, Cr: 0.45, Cu: 0.25, The rest is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com