Whole stabilizer bar upper supporting plate for motor truck chassis

A technology for trucks and stabilizer bars, applied in vehicle components, interconnection systems, suspensions, etc., can solve the problems of misalignment of terminal assembly, use of materials, waste of processing time, etc., to save labor hours and production efficiency. High and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

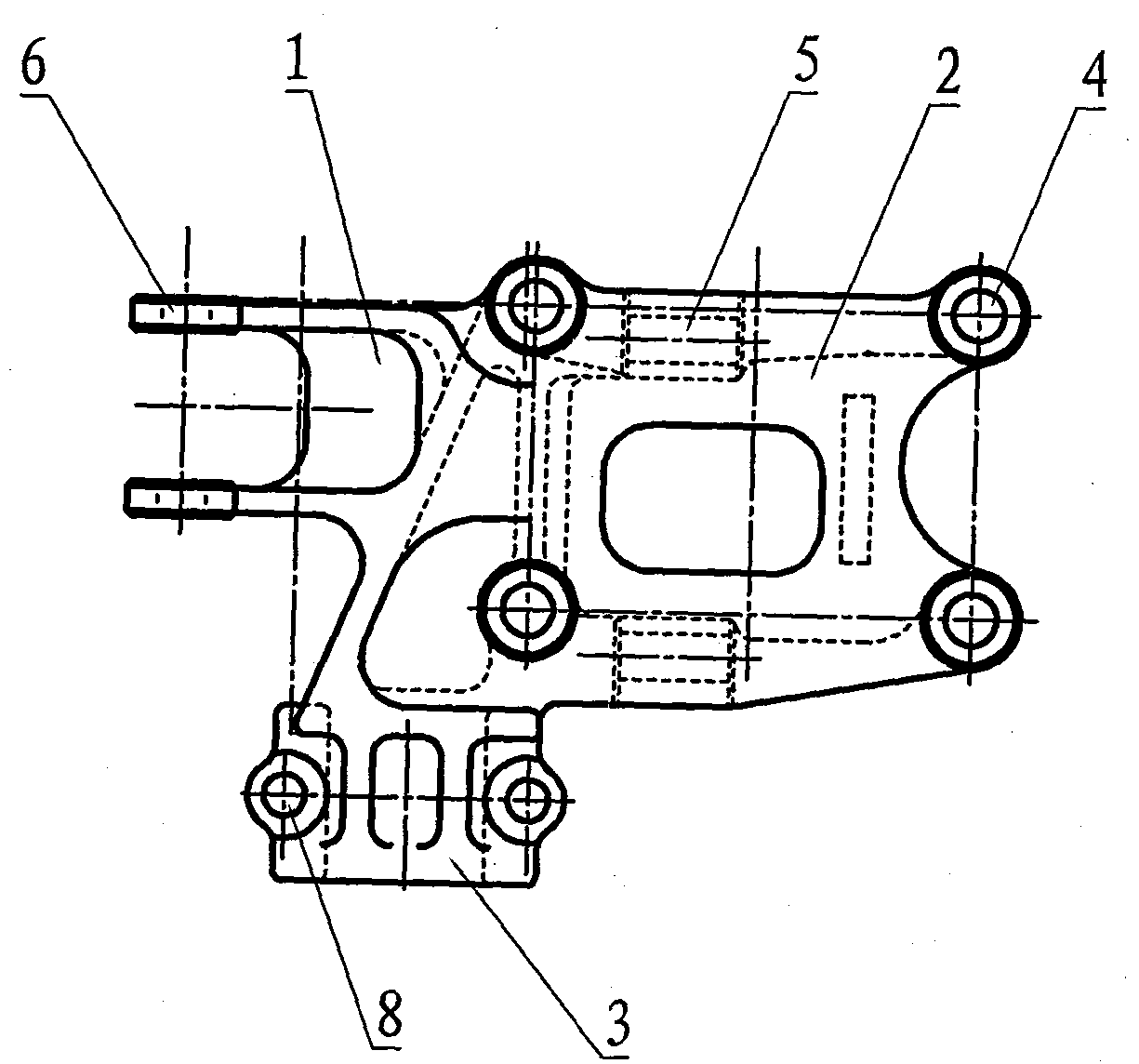

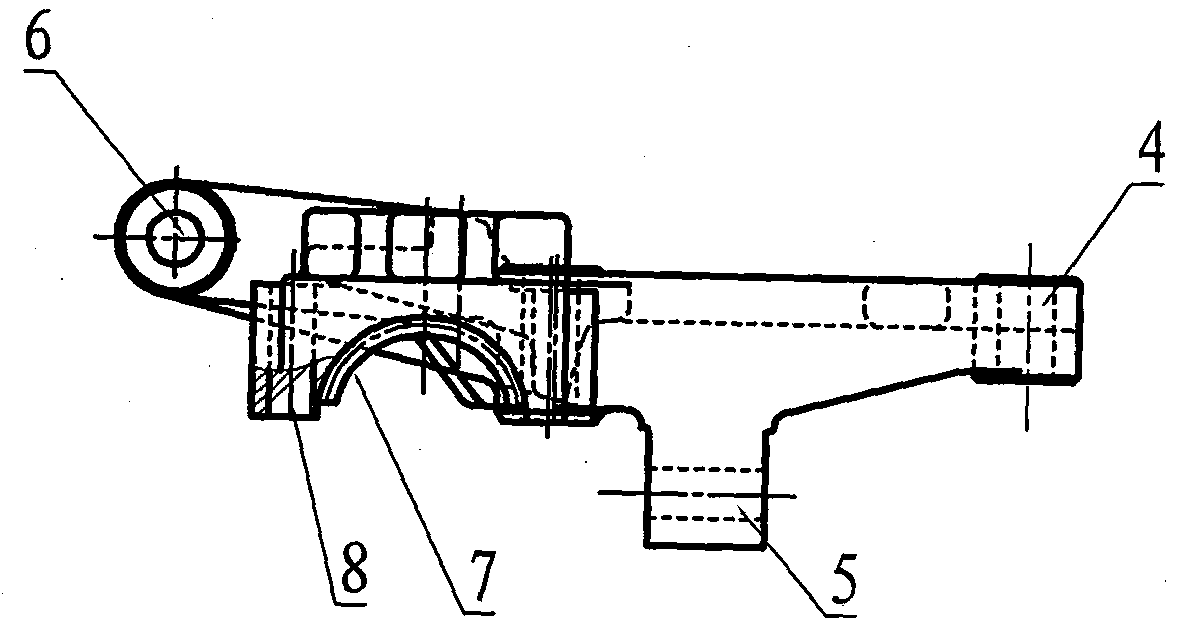

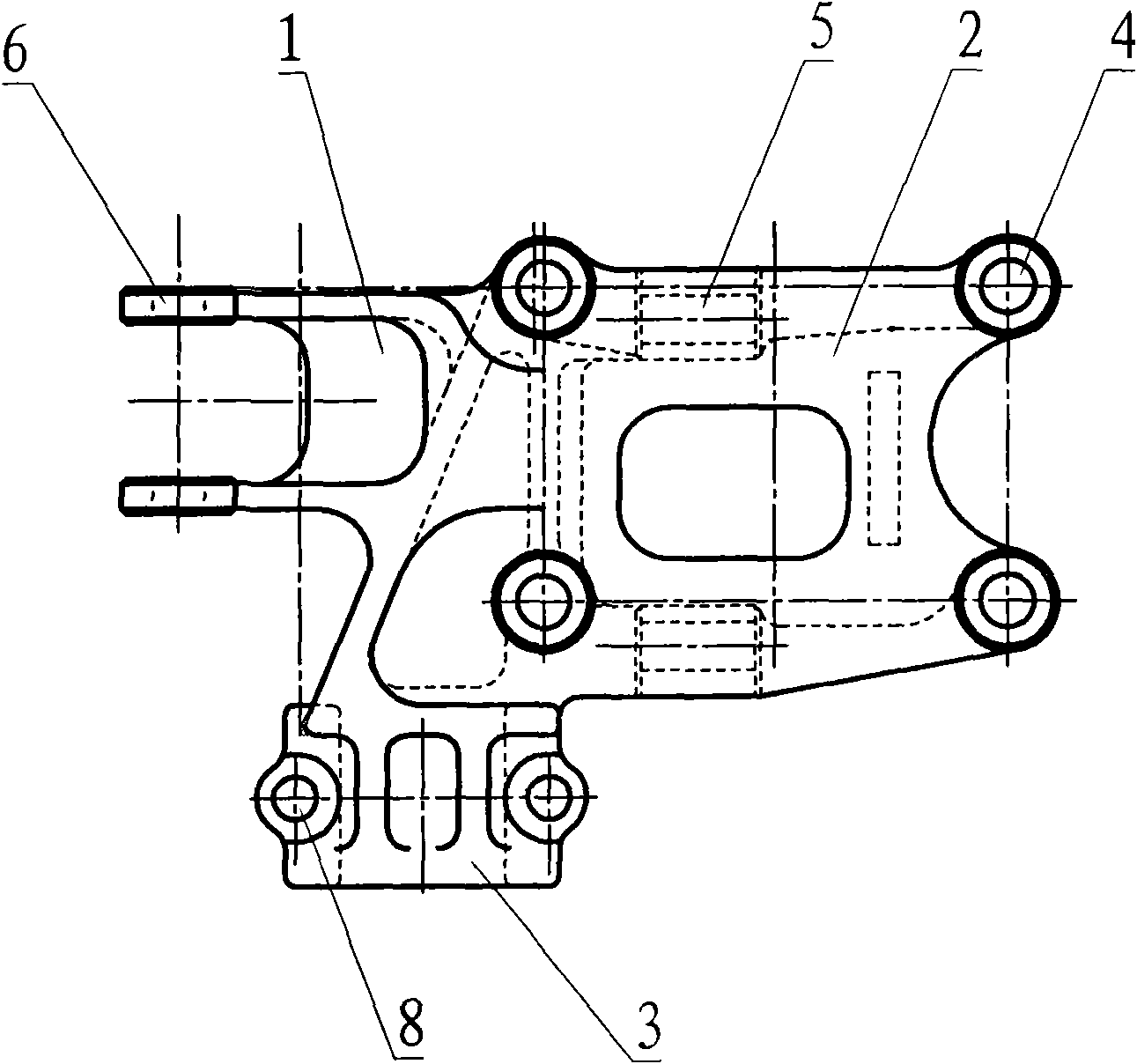

[0009] like figure 1 , 2 As shown, the present invention relates to an upper support plate of an integral stabilizer bar of a truck chassis, including a traction shaft support plate 1 , an axle support seat 2 and a stabilizer bar support seat 3 .

[0010] The above-mentioned traction shaft support plate 1 and stabilizer bar support seat 3 are cast into a whole through the axle support seat 2, only need to carry out one-time single casting and mechanical cutting, the processing speed is fast, the production efficiency is high, and it can be cut during cutting. The processing is completed according to the same benchmark and fixture, which avoids the cumulative error caused by the single processing of the three parts and improves the assembly accuracy. The specific structure is: the middle part is the axle support seat 2, and there are four mounting holes 4 distributed in a rectangular shape on it, which are used to fix the components on the chassis of the truck, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com