Method for suppressing low-speed oscillation of hybrid stepper motor

A stepper motor and hybrid technology, applied in the direction of motor generator control, electrical components, control systems, etc., can solve the problems of reducing the reliability of the drive system, increasing the hardware cost of the drive system, and increasing the system cost

Inactive Publication Date: 2010-08-25

FUZHOU UNIV

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Coaxial installation of speed or acceleration sensors constitutes speed or acceleration negative feedback, which can effectively suppress low-speed oscillations, but increases the hardware cost of the drive system and reduces the reliability of the drive system

It is also possible to use the method of adding reactive devices to suppress rotor oscillation, but the original drive hardware system needs to be redesigned, and there is also the problem of increasing system cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

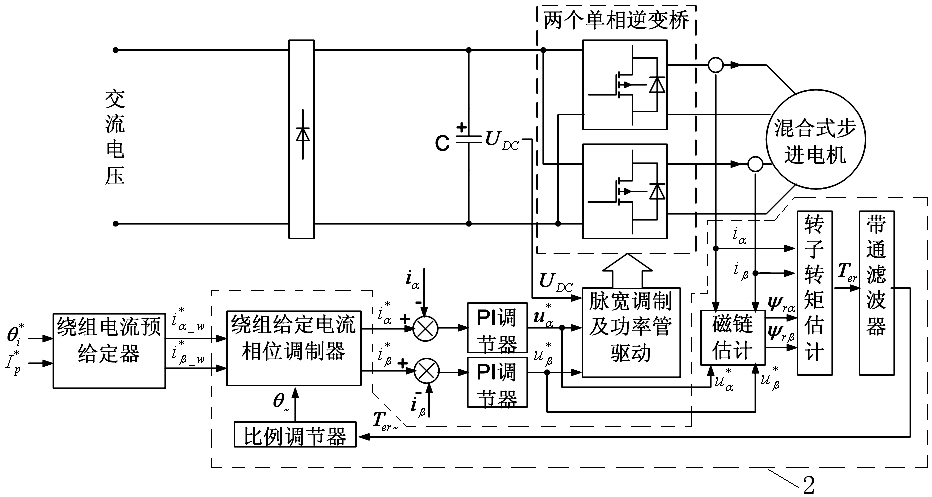

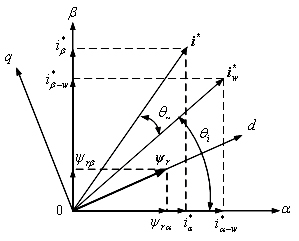

The invention relates to a method for suppressing low-speed oscillation of a hybrid stepping motor, which is characterized in that: according to feedback winding currents and given winding voltages existing in the micro-step control system of a hybrid stepping motor, adopting a magnetic chain estimator, a rotor torque estimator, a band-pass filter and a proportion regulator to effectively inhibit the given winding current phase angle modulation quantity in low-speed rotor oscillation, and then adopting a given winding current phase modulator and a closed-loop type winding current control mode to realize the real-time modulation of the actual winding current phase, thereby suppressing the low-speed rotor oscillation. The control method of the invention is applicable to both two-phase hybrid stepping motors and multi-phase hybrid stepping motors. Moreover, no additional speed or acceleration sensors, idling devices and the like are required, thereby reducing the cost of the stepping driver.

Description

technical field The invention relates to a method for suppressing low-speed oscillation of a hybrid stepping motor. Background technique The rotor of the hybrid stepping motor is excited by permanent magnets. The motor has the advantages of large output torque and high efficiency when it is working. It is widely used in CNC machine tools, engraving machines, embroidery machines, medical equipment and other occasions that require precise position control. However, the motor works in a stepping state, and the damping oscillation coefficient of the motor itself is very small, so that severe rotor oscillations will occur at some speed points in the low-speed operating area, which greatly limits the operating speed range of the motor. For a hybrid stepper motor with a 50-tooth rotor, the typical rotational speed when oscillation occurs is about 1r / s, 2r / s, 4r / s. The present invention aims at the problem of low-speed oscillation of the hybrid stepping motor, and proposes an effec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02P8/32

Inventor 周扬忠

Owner FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com