Slewing bearing with adjustable gear meshing center distance and machining method thereof

A technology of slewing bearing and center distance, which is applied in belts/chains/gears, components with teeth, portable lifting devices, etc., to achieve the effect of reducing requirements, reducing production costs, and increasing the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

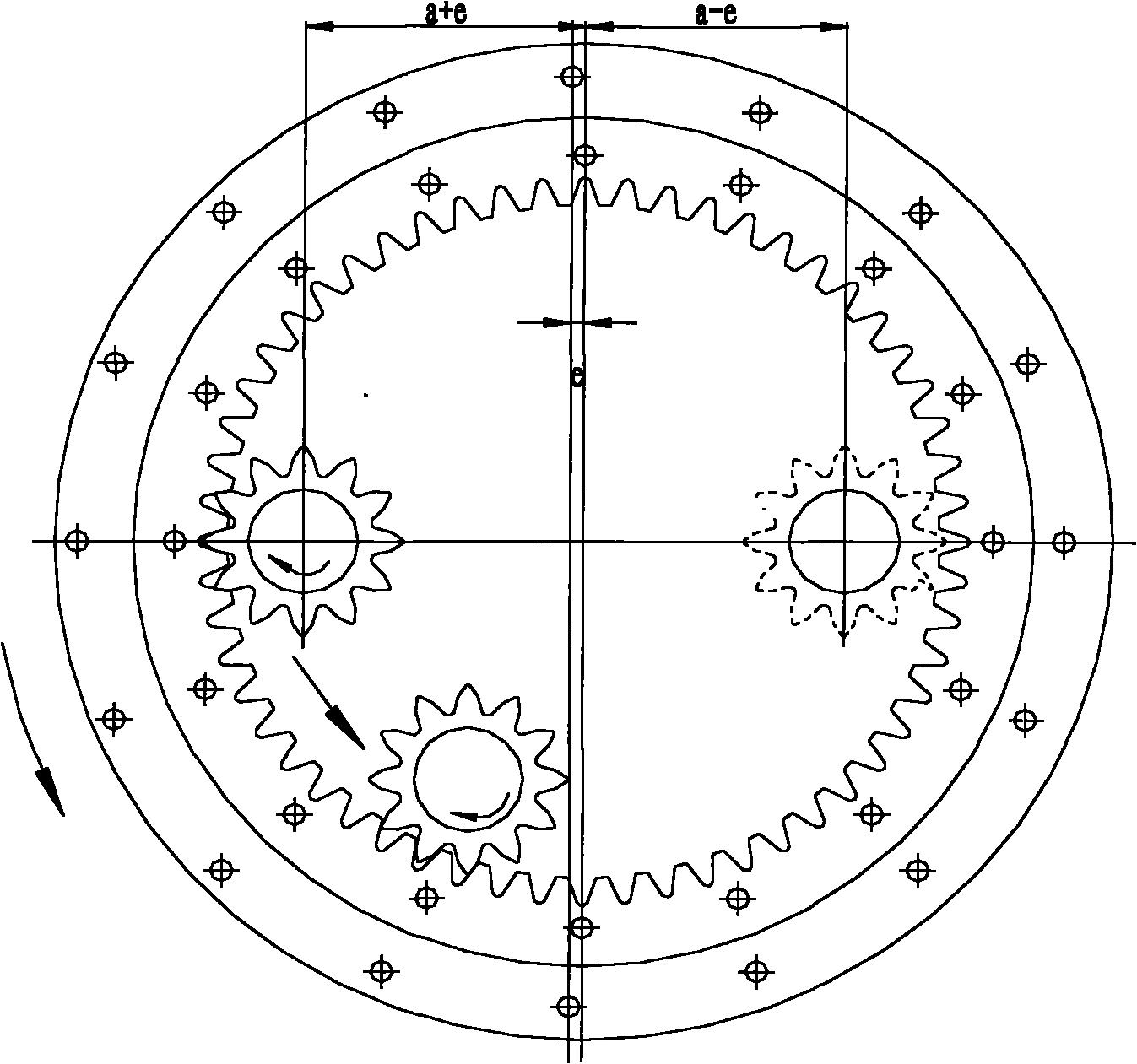

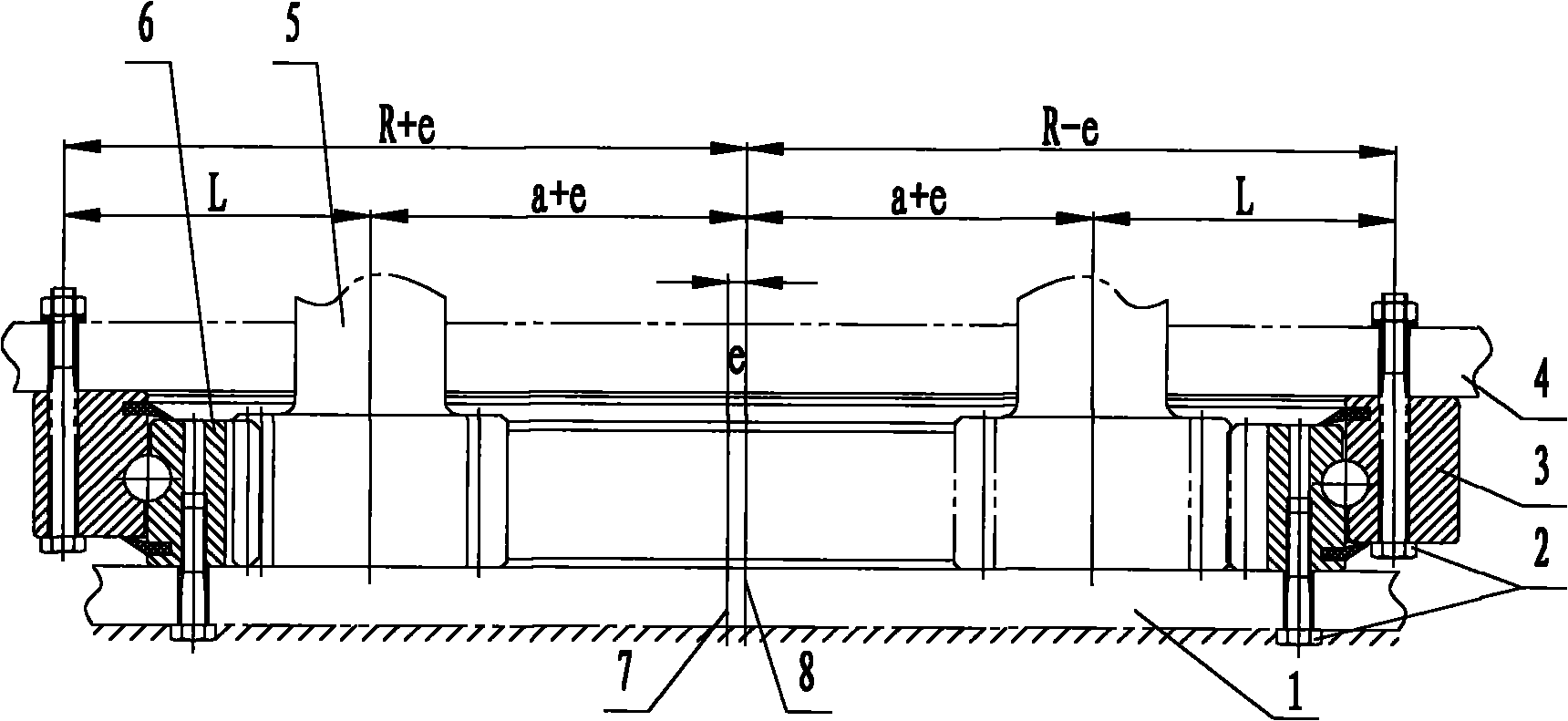

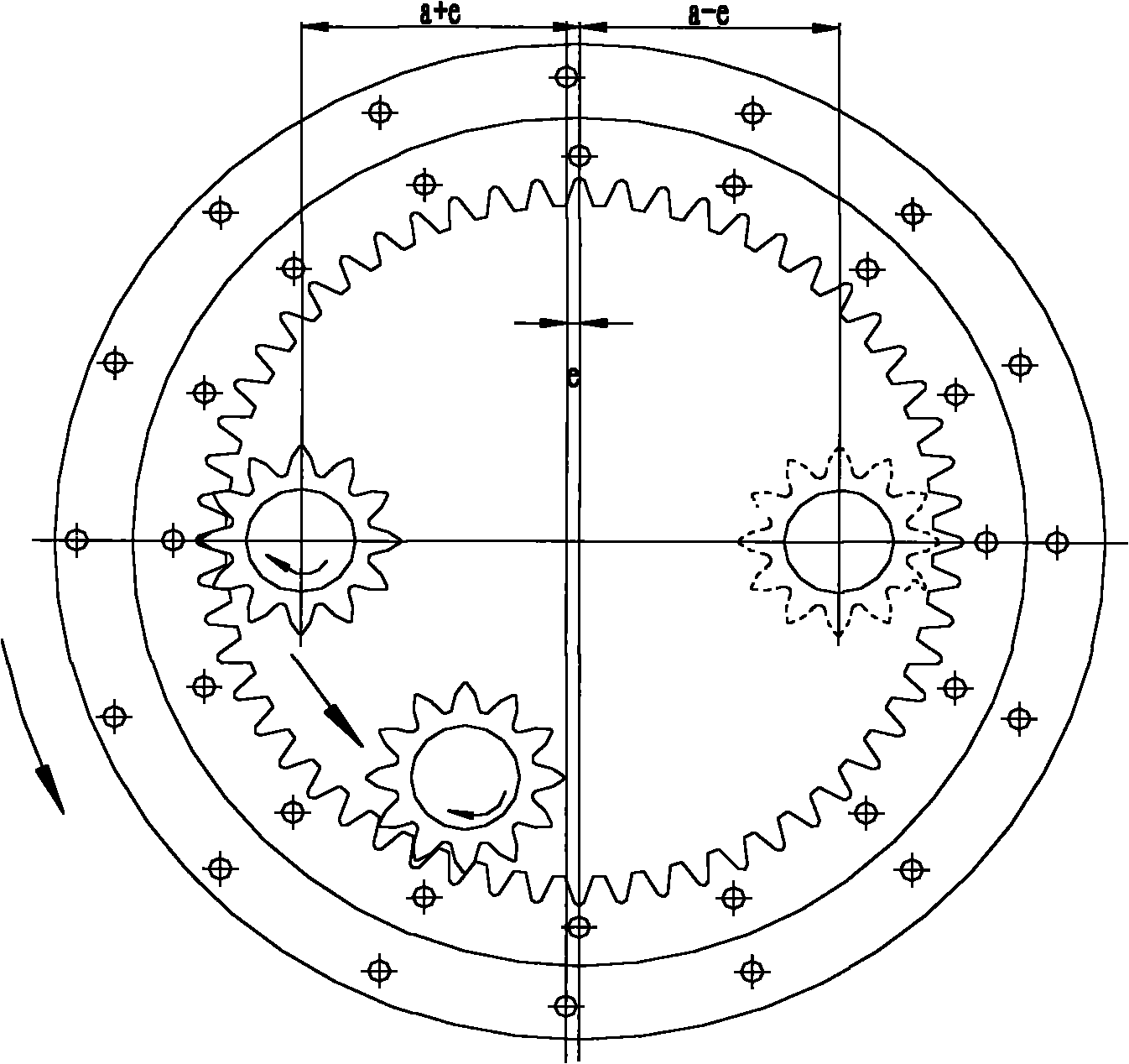

[0023] In the gear meshing center distance adjustable slewing bearing of the present invention, the center of the distribution circle of the installation hole of the ring-free support ring in the internal gear type and the external gear type slewing bearing and the center of the entire slewing bearing are changed from the original coaxial design to Eccentric design, the eccentricity is e, this structure is suitable for all toothed slewing bearings.

[0024] 1. Take the excavator slewing bearing as an example to illustrate:

[0025] It can be seen from Fig. 1 and Fig. 2 that the outer ring 3 of the slewing bearing for the excavator is without gear, and the inner ring 6 is with gear. The inner ring 6 is fixed, and the outer ring 3 rotates around the raceway; the chassis part 1 of the excavator is connected to the inner ring 6 of the slewing bearing through the connecting bolt 2, and the upper frame 4 of the excavator is connected to the outer ring 3 of the slewing bearing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com