Suspension support speed reducing transmission device

A technology of reduction transmission and reducer, which is applied in the field of reduction transmission and suspension support reduction transmission, which can solve the problems of repeated impact, failure of transmission keys, inability to adjust the mutual position of the motor and the primary reducer, etc., to achieve convenient disassembly and assembly, and convenient The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

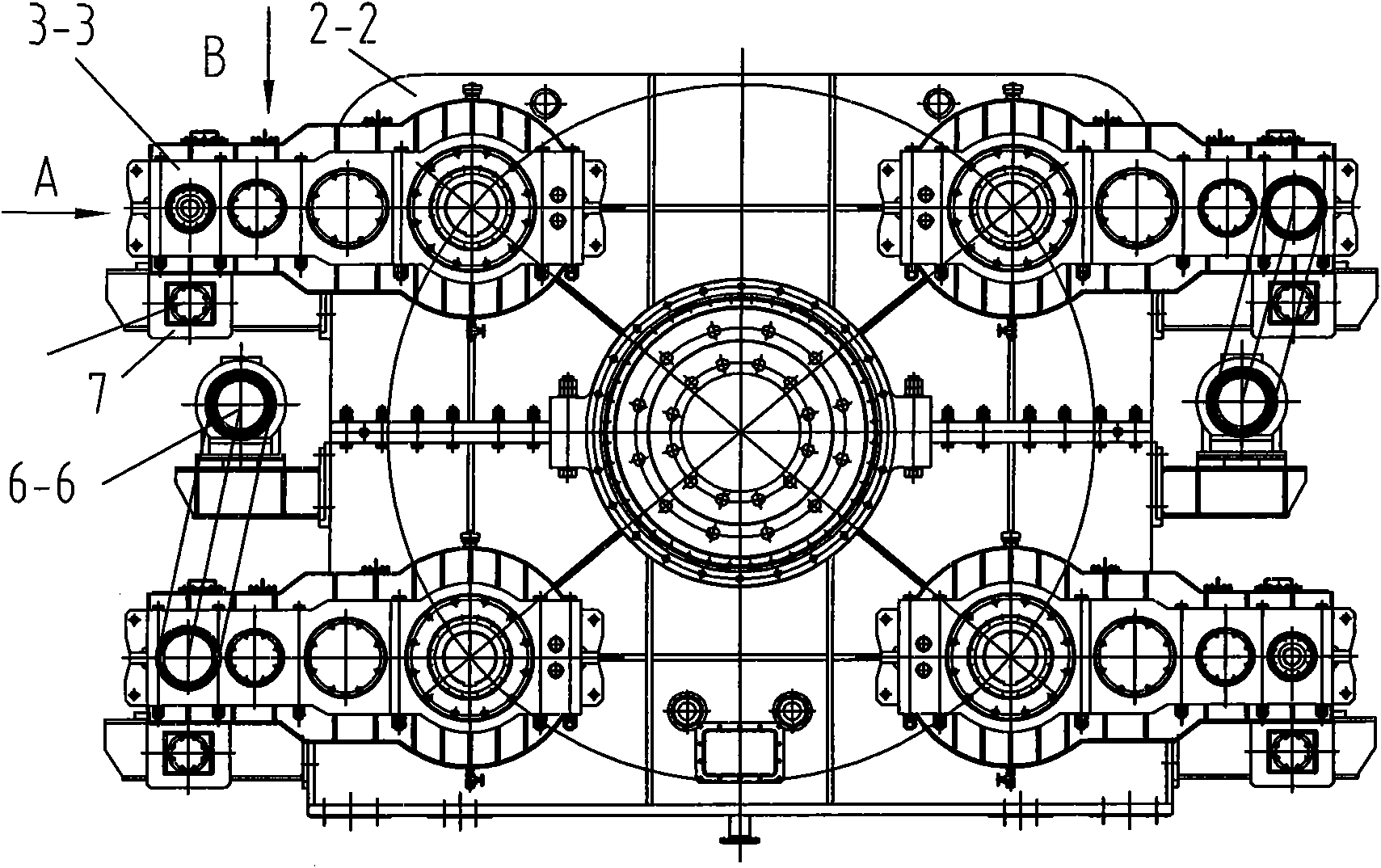

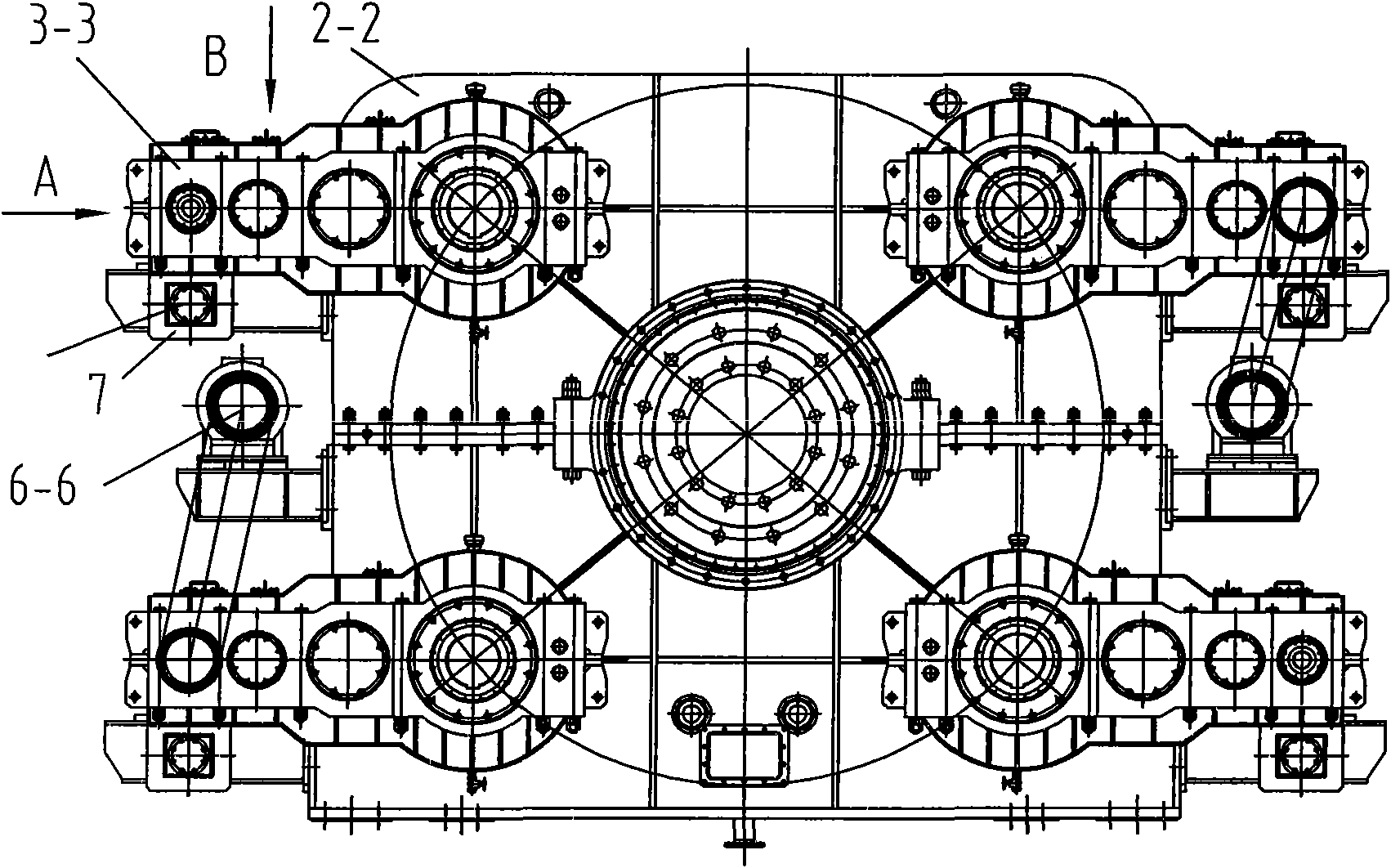

[0016] This embodiment is a suspension support deceleration transmission device adopted by a converter tilting mechanism in the iron and steel smelting industry. As shown in Figure 1, the four groups of motors drive the secondary decelerator 2-2 through their respective primary decelerators 3-3, two of which A primary reducer also drives the air motor 6-6 through the belt drive simultaneously.

[0017] As shown in Fig. 2 and Fig. 3, the motor 1-1 is installed on the motor support 4-4, and the motor support is fixedly connected with the casing of the secondary reducer 2-2. The output shaft of the motor 1-1 is coupled with the input end shaft of the primary reducer 3-3, and the gear sleeve 18 as the output end of the primary reducer is directly coupled with the gear shaft 17 as the input end of the secondary reducer. The specific structure is a gear shaft 17 is connected with the gear sleeve 18 through a key, and the gear shaft 17 is fixed on the gear sleeve 18 with the bolt 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com