Plane joint manipulator

A technology of planar joints and manipulators, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high technical content, high cost of grabbing manipulators or robots, and achieve reduced inertial coupling, simple mechanism kinematics and dynamics models, The effect of improving movement precision

Inactive Publication Date: 2010-08-25

WUHAN RENTIAN PACKAGING TECH

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The first two cartoning machines are widely used due to their small difficulty and relatively low cost. However, with the individual needs of customers for external packaging and the diversity of material shapes, drop-type and side-push cartoning machines are widely used It is difficult to realize the functional requirements in the packing of many materials, and the desire of customers for the grabbing cartoning machine is increasing day by day. There are limitations in the popularization and application of grabbing case packers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

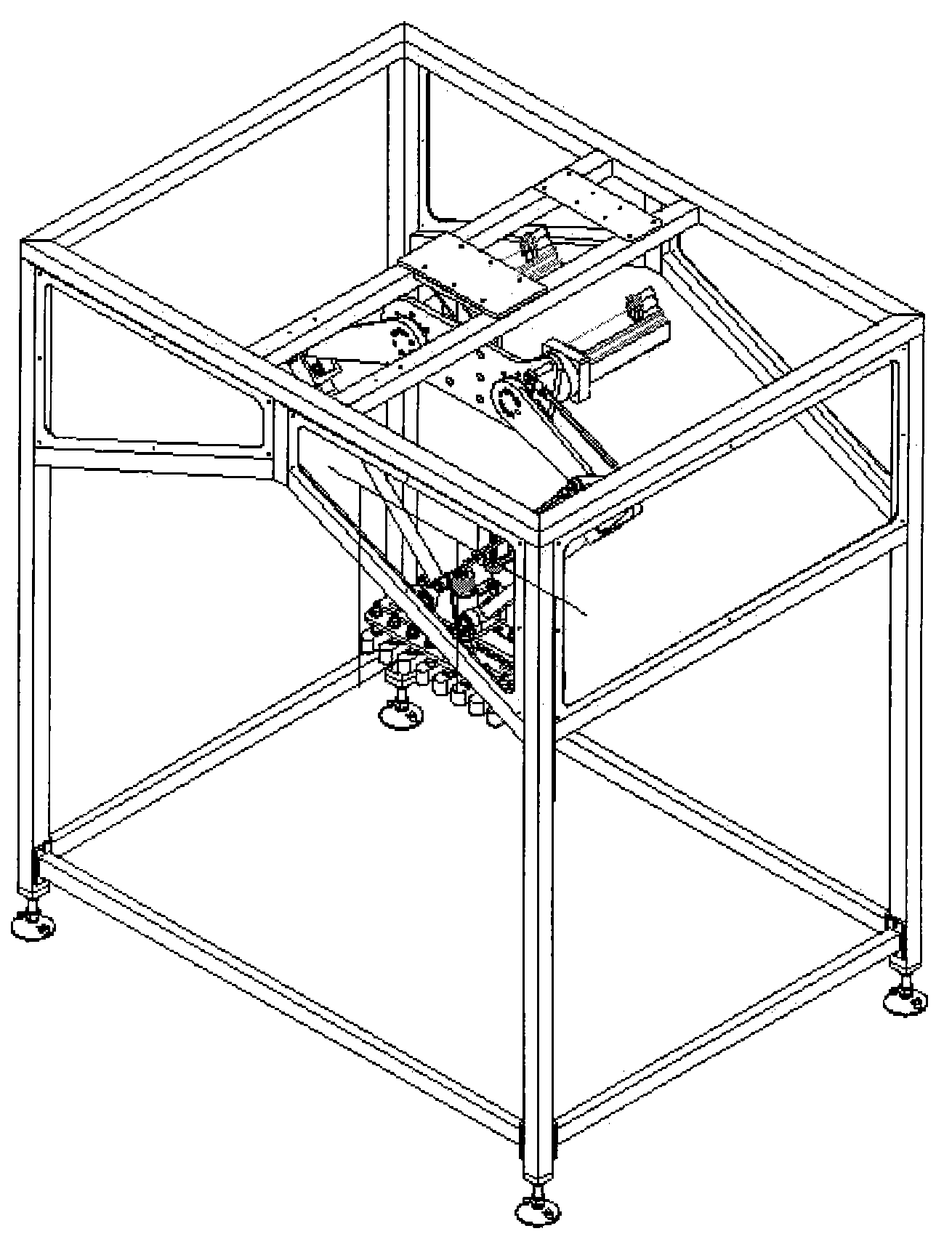

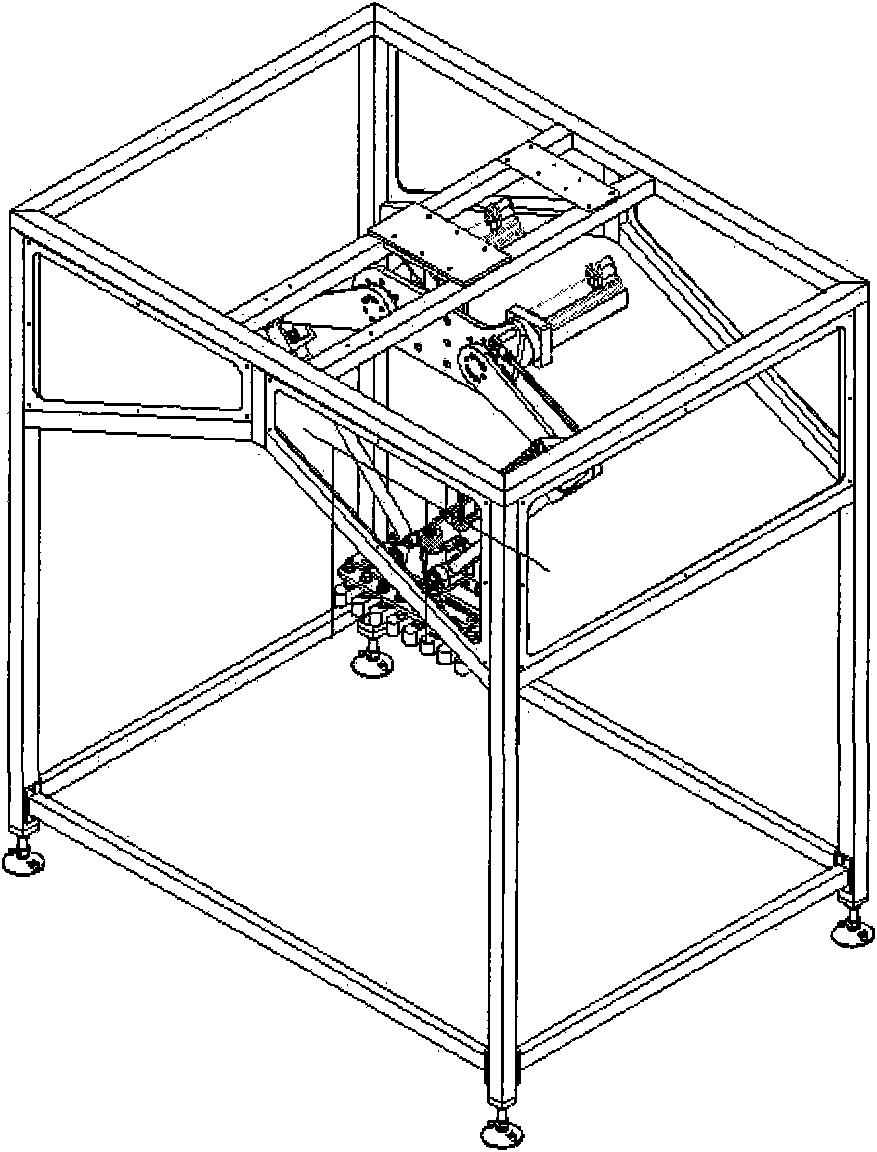

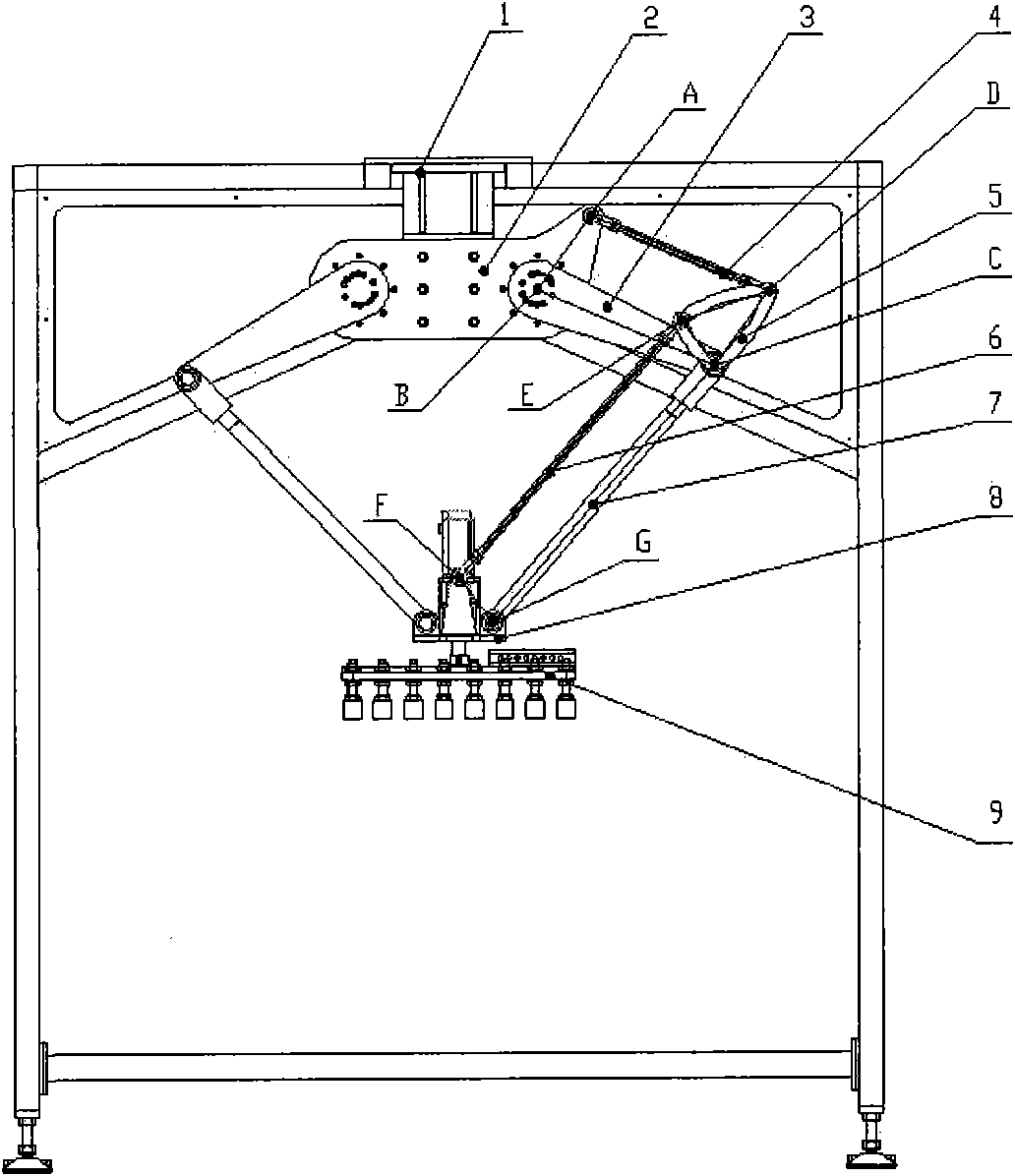

The invention relates to a plane joint manipulator which has the following connection modes: an installation rack is connected together with a stand, one ends of two swinging arms are respectively connected with the installation rack, the other ends of the two swinging arms are respectively connected with a swinging rod, the other ends of the two swinging rods are respectively connected with a gripping rack, and the gripping rack is connected with a sucker component; one supporting point of a triangular arm is connected with the installation rack through a short connecting rod, the second supporting point of the triangular arm is connected with the gripping rack through a long connecting rod, and the third supporting point of the triangular arm is connected at the joint of one swinging arm and one swinging rod; and two servo motors are respectively installed on the installation rack, and each servo motor is connected with one swinging arm. The invention utilizes the advantages of higher rigidity mass ratio, easy improvement of kinematic accuracy and relative acquisition of simple mechanism kinematic and dynamic models of a parallel mechanism. Meanwhile, the two servo motors are fixed on an installation plate connected with the stand, thereby reducing the rotary inertia of the mechanism and the inertia coupling between the motors.

Description

Planar joint manipulator technical field The invention relates to a planar joint manipulator used for grabbing packing. Background technique At present, there are generally three types of box packers in the world: drop type, side push type and grab type. The first two cartoning machines are widely used due to their small difficulty and relatively low cost. However, with the individual needs of customers for external packaging and the diversity of material shapes, drop-type and side-push cartoning machines are widely used It is difficult to realize the functional requirements in the packing of many materials, and the desire of customers for the grabbing cartoning machine is increasing day by day. There are limitations in the popularization and application of grabbing case packers. Contents of the invention The purpose of the present invention is to overcome the problems and shortcomings of the above-mentioned prior art, and to provide a planar joint manipulator based o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25J9/08B25J17/00B25J15/06

CPCB25J9/107

Inventor 李浩方磊包仕林李怀刚谢烽

Owner WUHAN RENTIAN PACKAGING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com