Geocomposite evapotranspiration plugged structure of refuse landfill

A technology for landfill and garbage, which is applied in landfill technology, solid waste removal, etc., can solve problems such as water storage capacity limitations, and achieve the effects of convenient construction, wide applicability, and ability to withstand uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

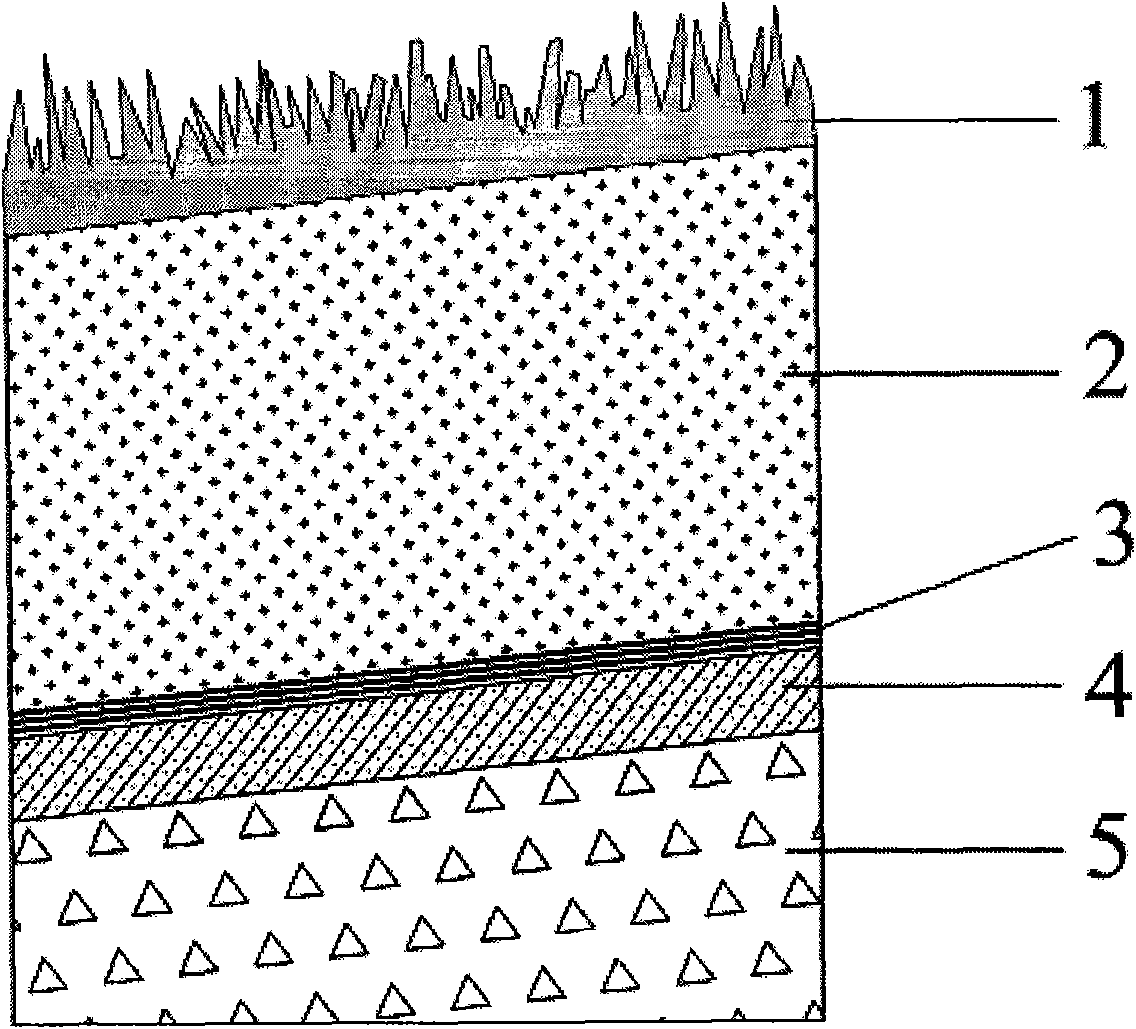

[0015] Embodiment one: referring to Fig. 2, the geotechnical composite capping structure of this refuse landfill includes covering the regulating soil layer 4, the vegetation growth soil layer 2 and the vegetation layer 1 from bottom to top on the garbage 5, and adjusting the soil layer 4 and the vegetation layer 1. A layer of geotechnical composite bentonite pad 3 is laid between the vegetation soil layers 2 .

Embodiment 2

[0016] Embodiment two: referring to Fig. 2, this embodiment is basically the same as embodiment one, and the special features are as follows:

[0017] The geotechnical composite bentonite pad 3 is a sandwich-type composite soil pad with calcium-based or sodium-based bentonite sandwiched between two layers of geotextiles, and its thickness is 5 mm to 10 mm. Vegetation layer 1 is evergreen vegetation, or mixed vegetation of vegetation and shrubs. Vegetation growth soil layer 2 is a single soil layer with strong water holding capacity and suitable for vegetation growth or multi-layer soil containing humus, slag and the like. The regulating soil layer 4 is fine-grained soil for leveling and protection, or fine-grained and coarse-grained double-layered soil for air conduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com