Vibrating screen with hydraulic cylinder

A technology of hydraulic cylinder and vibrating screen, which is applied in the direction of filter screen, solid separation, grille, etc., which can solve the problems of serious resonance phenomenon, affecting the life of the machine body, long startup and shutdown time, etc., to achieve stable operation and increase the excitation force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

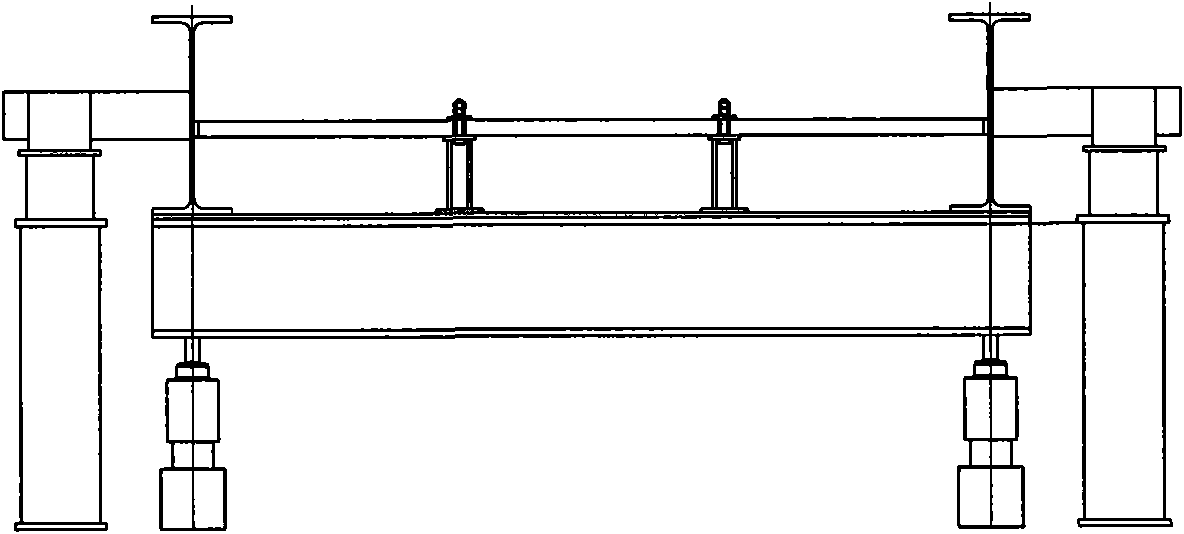

[0012] As shown in Figures 1 and 2: the present invention includes a screen body 1, a screen body excitation beam 2, a pump station system 4, an underframe 5, a hydraulic cylinder 6, a fixing element 7, a bracket 8, a shock-absorbing spring 9, and a screen body 1 is supported on the bracket 8 by the shock absorbing spring 9, one end of the hydraulic oil pipe 3 is connected to the pump station system 4, the other end of the hydraulic oil pipe 3 is connected to the hydraulic cylinder 6, the hydraulic cylinder 6 is fixed on the chassis 5, and the hydraulic cylinder 6 passes through The fixing element 7 is connected with the vibrating beam 2 of the sieve body.

[0013] The pumping station system described is prior art.

[0014] The sieve body 1 is an inclined device, and its inclination angle α is 10°-30°.

[0015] The bottom of the screen body 1 is evenly distributed with hydraulic cylinders 6 symmetrically. The reciprocating motion of the hydraulic cylinders drives the vibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com