Electromagnetically-focused concentration machine

A selection machine and electromagnetic technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high cost and low utilization rate of magnetic field, and achieve the effect of reducing equipment cost and improving utilization rate of magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and specific embodiments.

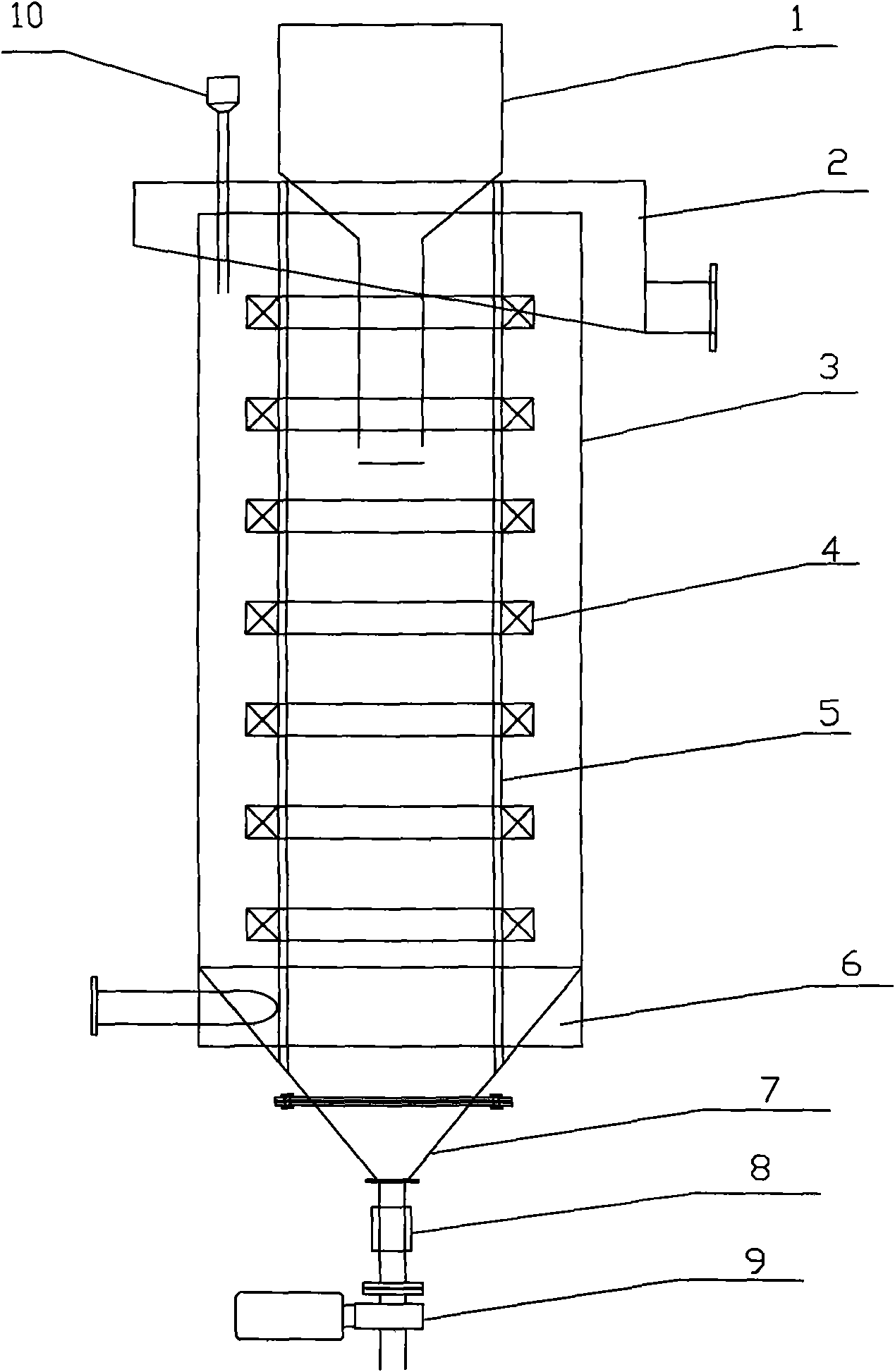

[0014] As shown in Figure 1, the electromagnetic concentrating and concentrator of the present invention consists of a ore hopper and a ore pipe 1, a tailings overflow tank 2, a sorting barrel 3, an excitation coil 4, an excitation coil support 5, a water supply bag 6, and a concentrate funnel 7. , Concentrate density sensor 8, concentrate discharge valve 9, tailings overflow density sensor 10, the sorting barrel 3 is provided with multiple layers of excitation with waterproof and wear-resistant protective layers from top to bottom through the excitation coil bracket 5 Coil 4, the excitation coil 4 on the uppermost layer is the excitation coil that supplies constant direct current to prevent the iron powder from overflowing with the tailings. The remaining excitation coils 4 are grouped and conducted sequentially, the conduction time and the current size are ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com