Double-layer smog chamber capable of controlling temperature

A smoke box and double-layer technology, applied in the field of smoke box, can solve the problems of reaction rate deviation, achieve temperature stability, reduce fluctuation, and increase repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

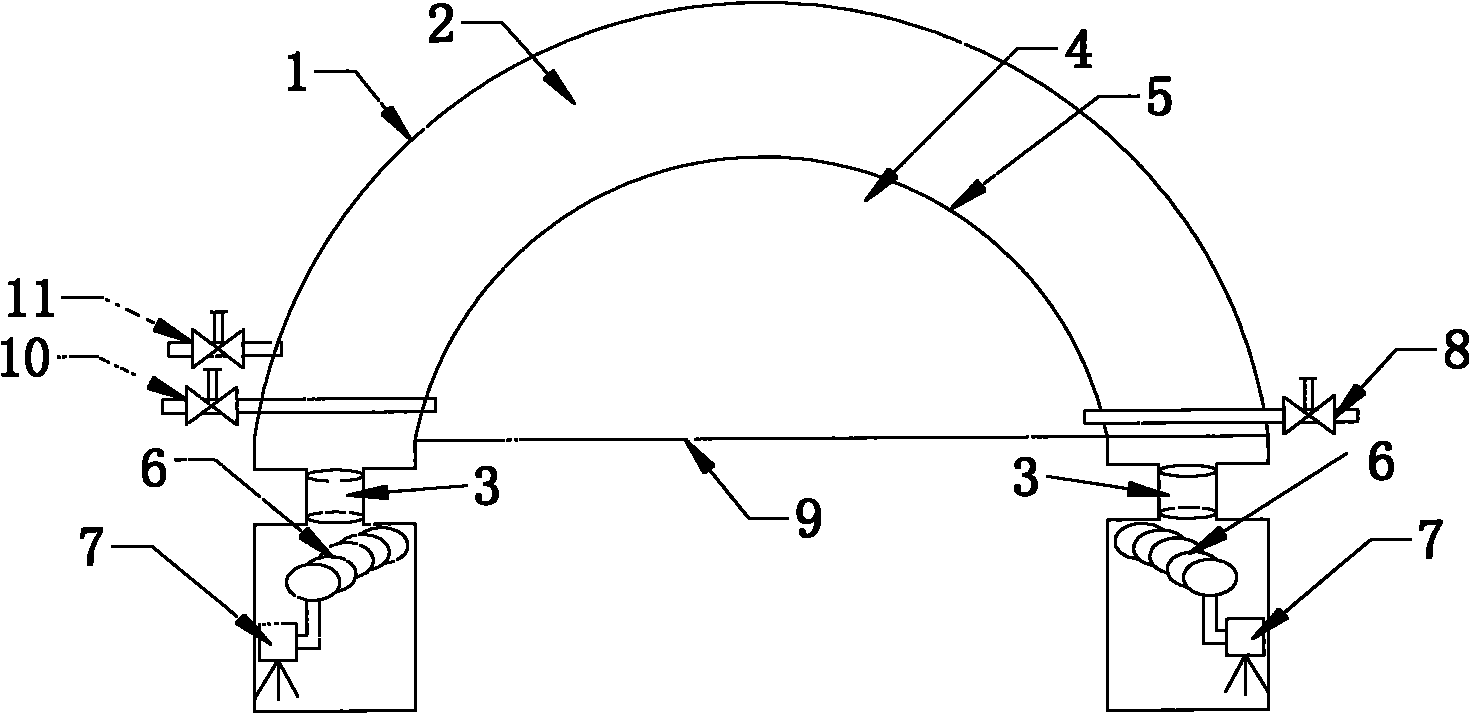

[0013] Such as figure 1 As shown, the double-layer smoke box is composed of the reaction cabin 4, the control cabin 2, the temperature control system and the gas circuit system. The main body of the smoke box is a double-layer structure, including the outer layer 1 and the inner layer 5, and the outer layer 1 and the inner layer 5. Both are light-transmitting materials; the control cabin 2 is the space between the outer layer 1 and the inner layer 5; the control cabin 2 is equipped with a control ventilation valve 11; the reaction cabin 4 is the space surrounded by the inner layer 5; the reaction cabin 4 is equipped with Reaction gas exchange valve 10 and sampling port 8. Both the reaction chamber 4 and the control chamber 2 are sealable spaces. The temperature control system includes a heat exchanger 6 . The temperature changing mode of the heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com