Forage mill mixer

A mixer and feed technology, applied in the direction of feed, food science, application, etc., can solve the problems of wind waste, large dust, no passing, etc., and achieve the effect of improving the flexibility of use, reducing dust emissions, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

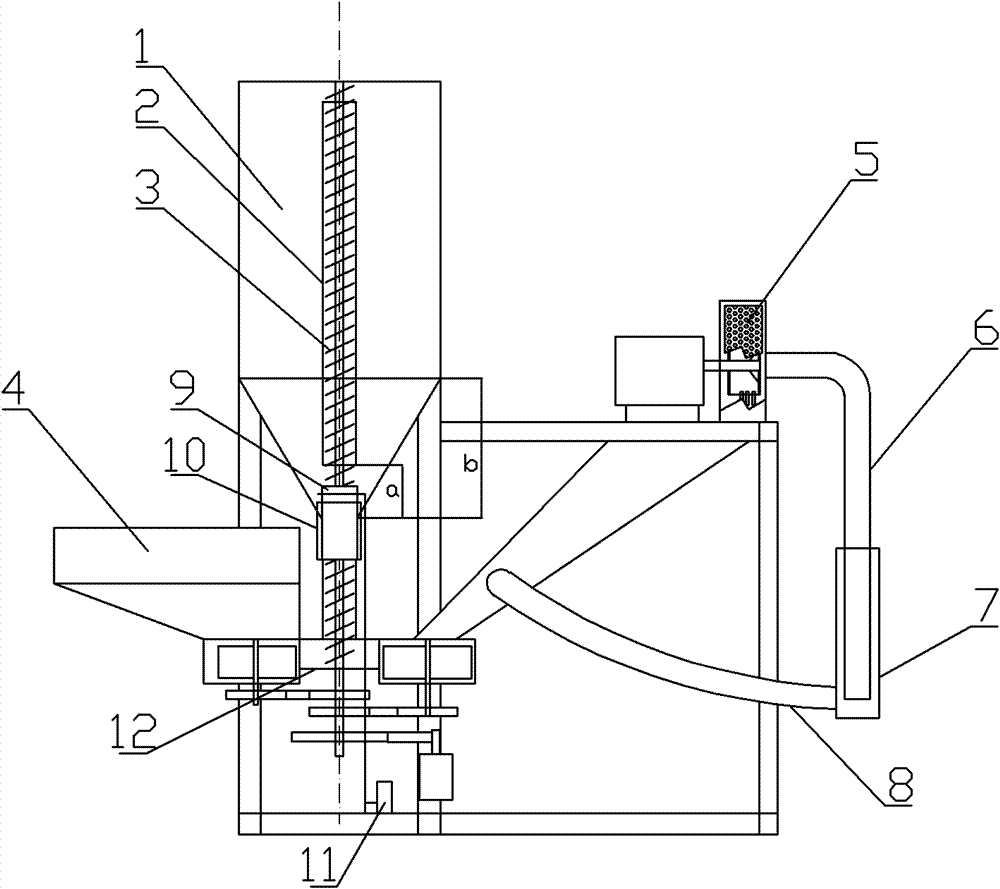

[0012] Such as figure 1 Among them, a feed pulverizing mixer includes a hopper 1, a conical section at the lower end of the hopper 1, the bottom of the conical section is connected with the mixing bin 12, and the auxiliary hopper 4 and the feeding pulverizing device 5 are connected with both sides of the mixing bin 12, after crushing After the feed and auxiliary materials are mixed in the mixing chamber 12, they are conveyed into the hopper 1 by the rotation of the conveying roller 3, and the ratio a:b of the distance a between the lower end of the conveying cylinder 2 in the hopper 1 and the bottom of the conical section and the height b of the conical section is as follows: 0.2~0.8. The specific distance can be adjusted according to the production capacity. For example, if you often need to stir a large amount of feed, you can increase the distance a between the lower end of the transmission cylinder 2 and the bottom of the conical section, and vice versa, so that less feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com