Shell manufacturing method

A manufacturing method and shell technology, which are applied to devices for coating liquid on surfaces, electrical equipment shells/cabinets/drawers, electrical components, etc. The effect of improving efficiency and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

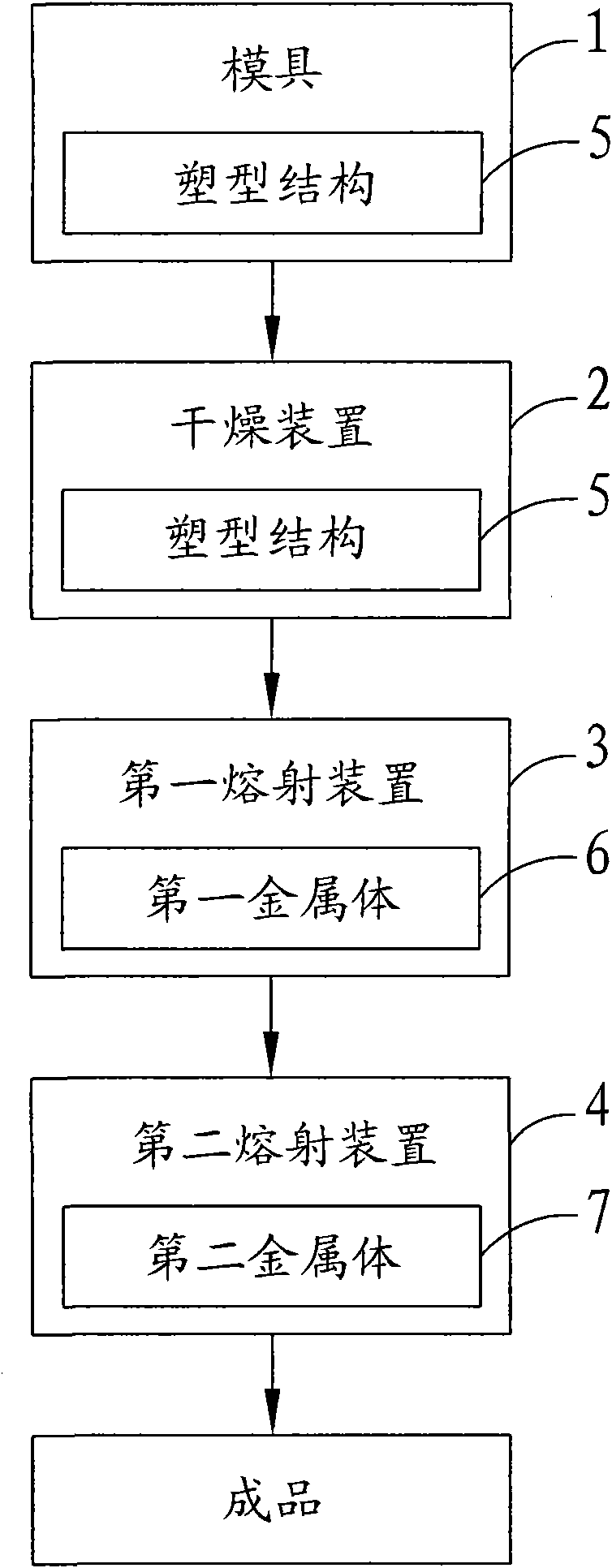

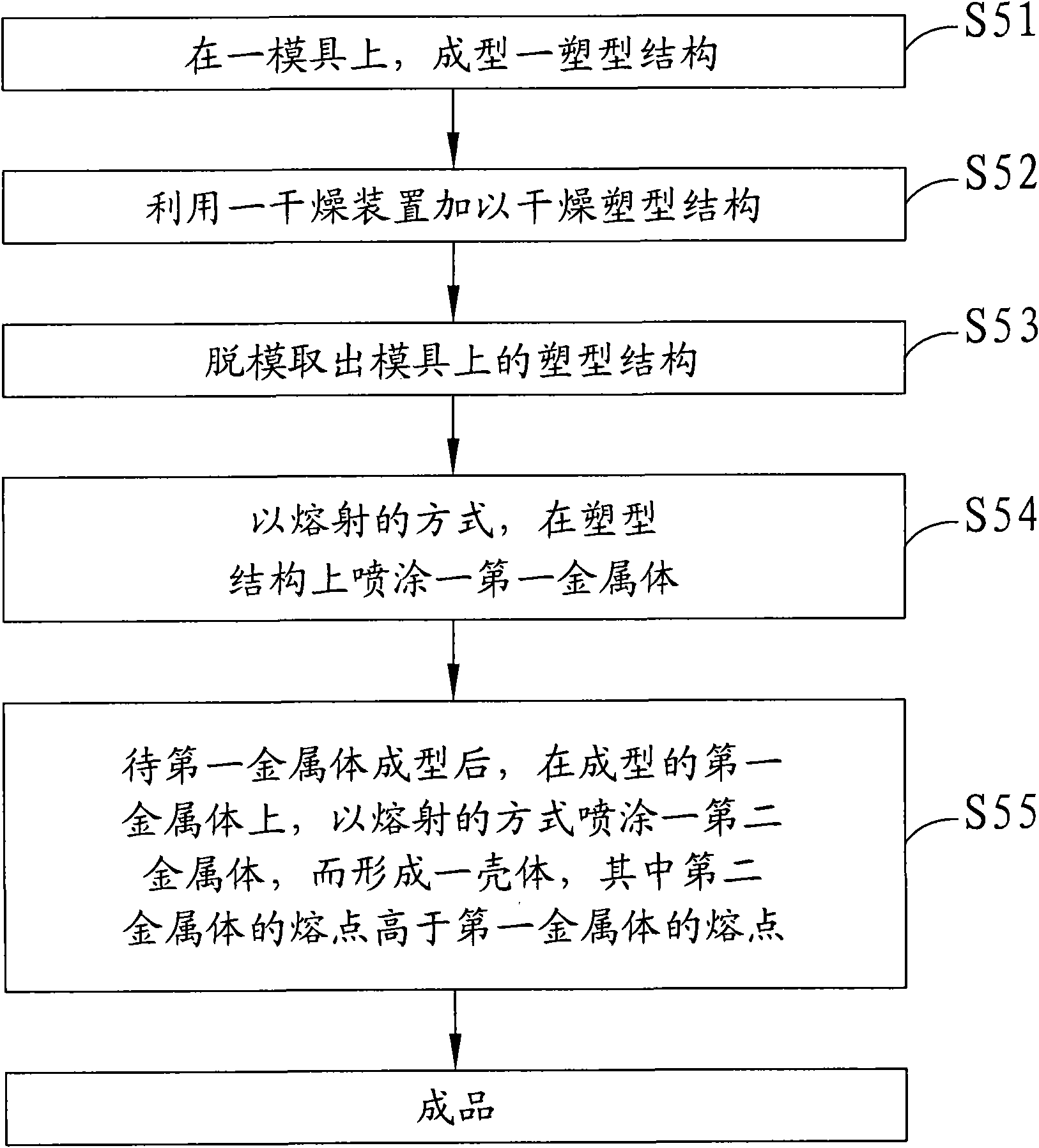

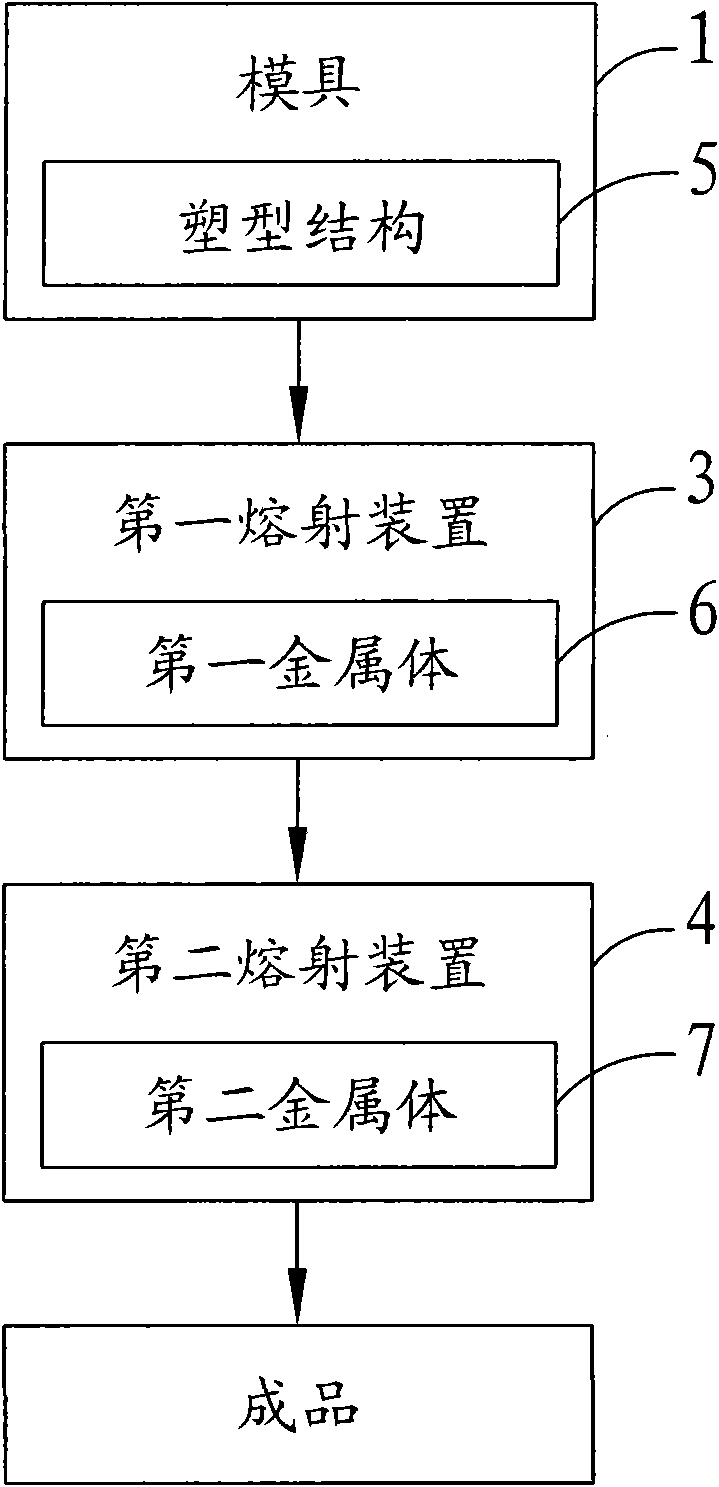

[0034] see figure 1 and figure 2 Shown are the device block diagram and step flow chart of the first embodiment of the shell manufacturing method of the present invention, respectively. The shell manufacturing method of the first embodiment of the present invention includes the following steps:

[0035] Step S51: On a mold 1, form a blister of a plastic structure 5, wherein the plastic structure 5 is made of a plastic material, the plastic material is a fiber, a soil or a clay, and the fiber can be a pulp . In this embodiment, it is represented by a pulp that has not been dried, but it is not limited to pulp;

[0036] Step S52: using a drying device 2 to dry the molded structure 5, wherein the way of drying the molded structure 5 can be a high-temperature gas drying method or an electric heating method;

[0037] Step S53: Demoulding and taking out the plastic structure 5 on the mold 1;

[0038] Step S54: Utilize the first spraying device 3 to spray a first metal body 6 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com