PIN needle dissembling device and PIN dissembling head

A technology of dismantling device and actuating device, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of fast dismantling of PIN needles, easy injury to equipment operators, broken PIN needles, etc., so as to improve production efficiency and reduce Production cost, effect of reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

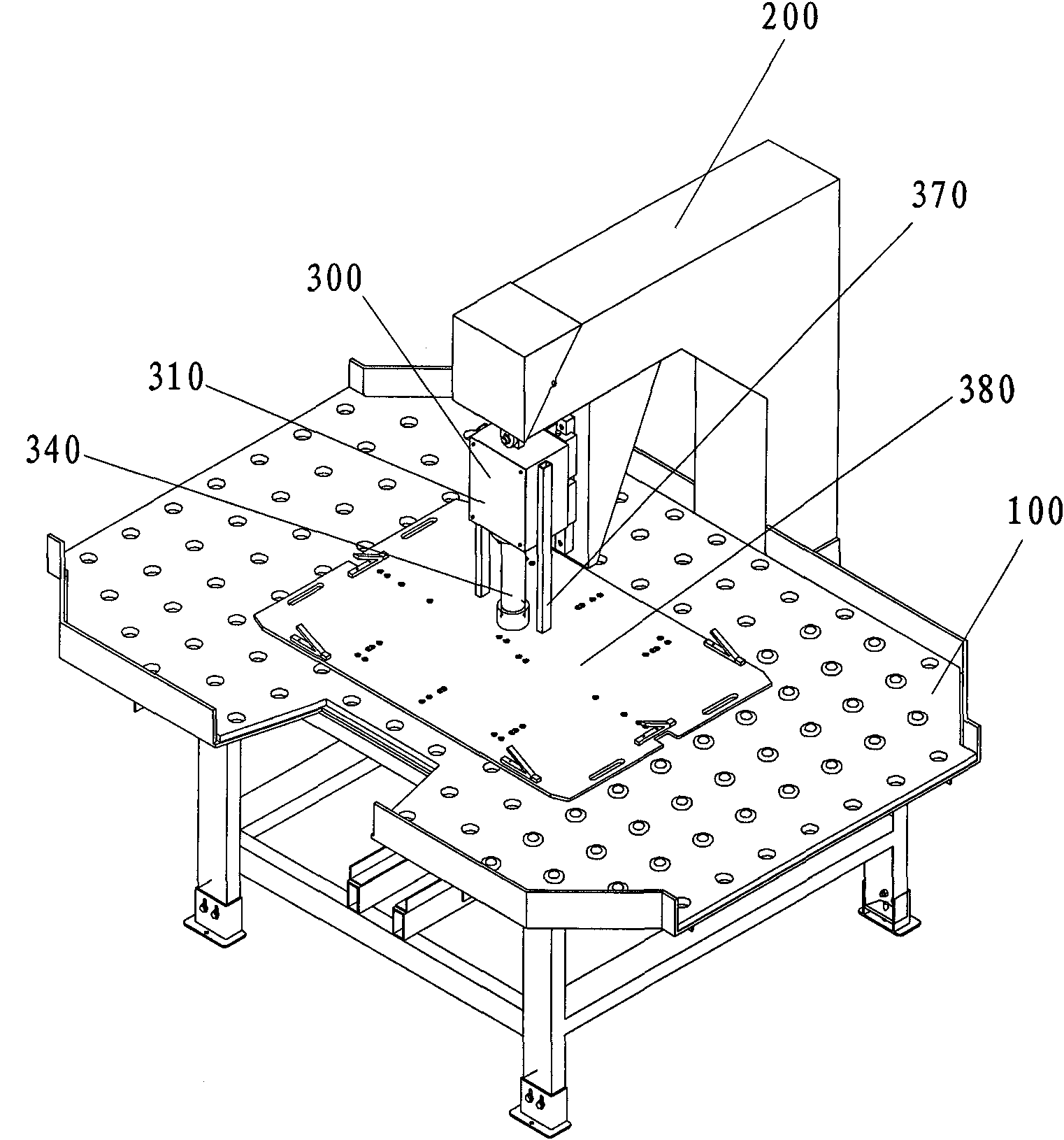

[0027] see figure 1 and figure 2 , the PIN pin removal device embodiment of the present invention comprises:

[0028] A workbench 100 carrying boards that need to be removed from the PIN;

[0029] a cantilever 200 located above the workbench 100;

[0030] The PIN needle fixed under the cantilever 200 removes the PIN head, and the PIN head includes:

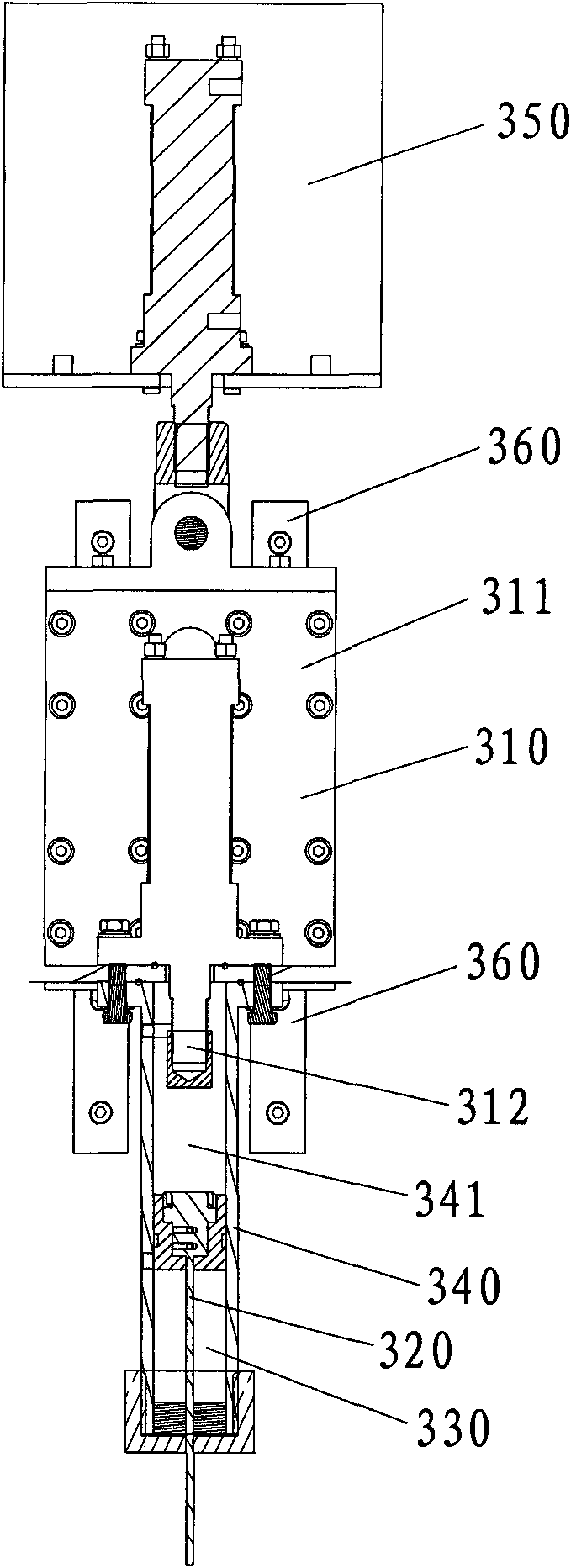

[0031] At least one actuating device 300, including a base 311 and an actuating rod 312 protruding from the base 311;

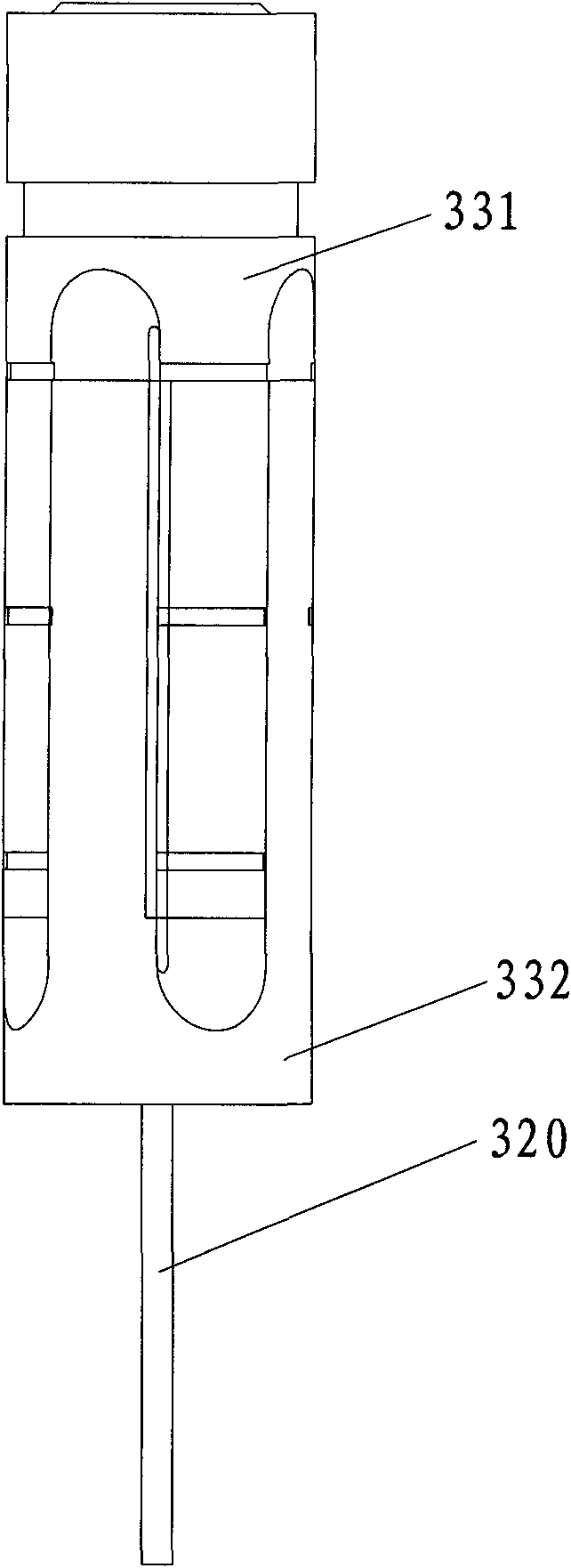

[0032]Corresponding to the end of the actuating rod 312 and coaxial with the actuating rod 312 is a PIN removal needle 320 and a protective sleeve 330 . refer to image 3 , Figure 4 and Figure 5 , the protective cover 330 includes a first sleeve body 331 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com