Powerless constant length cable traction mechanism

A technology of cable traction and power, which is applied in the direction of cable arrangement between relative moving parts, cable installation, electrical components, etc. It can solve the problems of unsuitable optical cables and affecting the life of cables, so as to save cable length and facilitate track Length, easy to change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

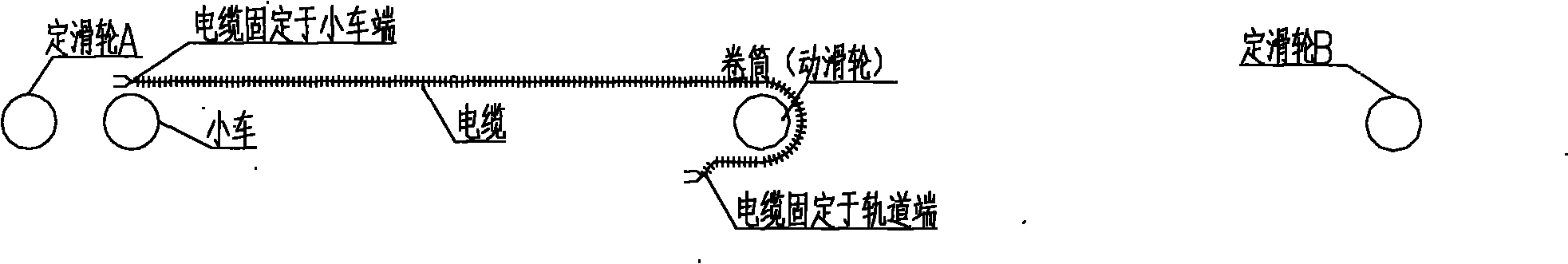

[0016] figure 1 It is the layout diagram of trolley, winding reel (moving pulley), fixed pulley relative to the track. Among them, the fixed pulley is fixed at both ends of the track, and the trolley and the reel can move along the track. Through the layout of the traction line, the distance from the trolley to the fixed pulley B is twice the distance from the reel to the fixed pulley B, that is figure 1 The L in is variable, but the L on both sides of the reel remains equal.

[0017] figure 2 A schematic diagram of the cable setup is given, one end of the cable is fixed in the middle of the track, and the other end is fixed on the trolley. The function of the reel is to guide the cable to change direction, and the radius of the wheel guiding the cable by the reel is determined according to the bending radius of the selected cable. From figure 2 It can be seen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com