Staged high-temperature combustion circulating fluidized bed system and combustion method

A circulating fluidized bed, high-temperature combustion technology, applied in fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve problems such as dioxin emissions and achieve high-efficiency utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

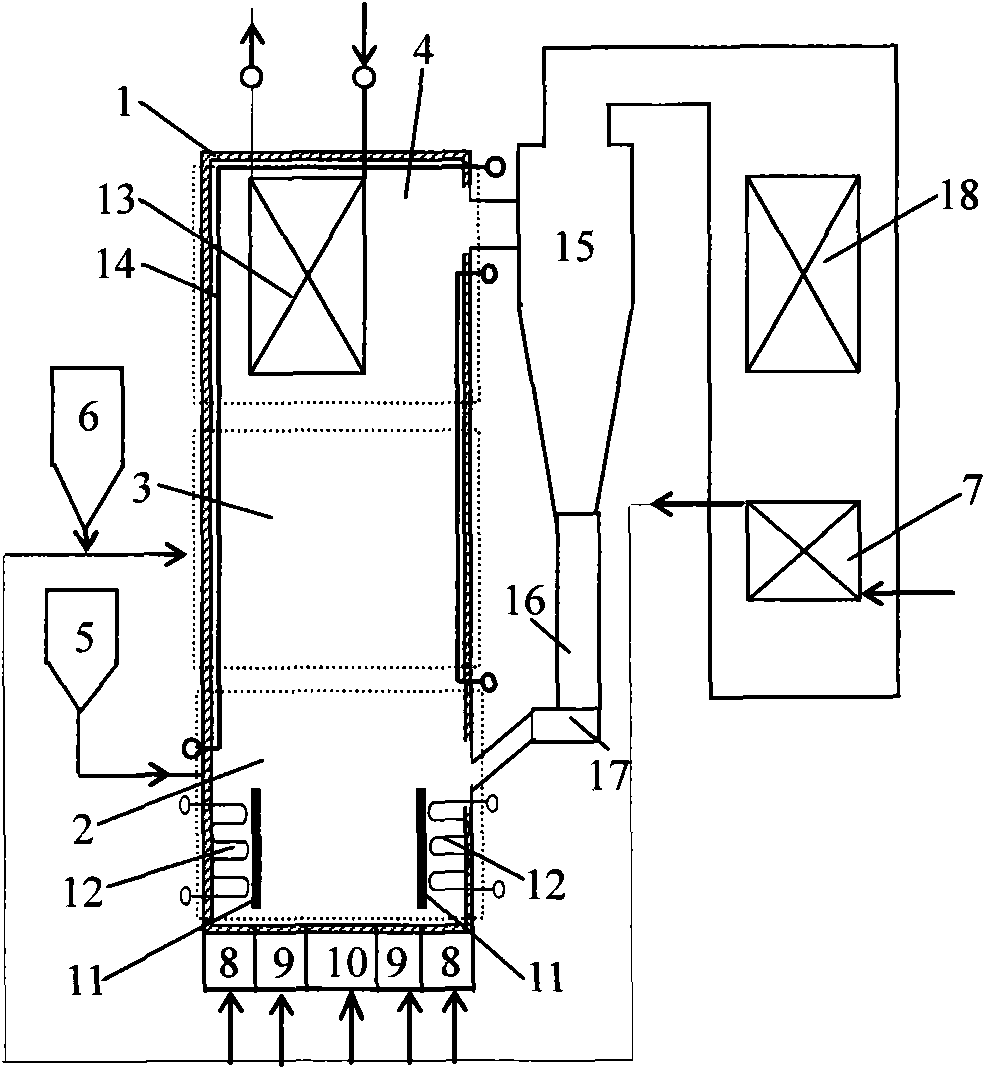

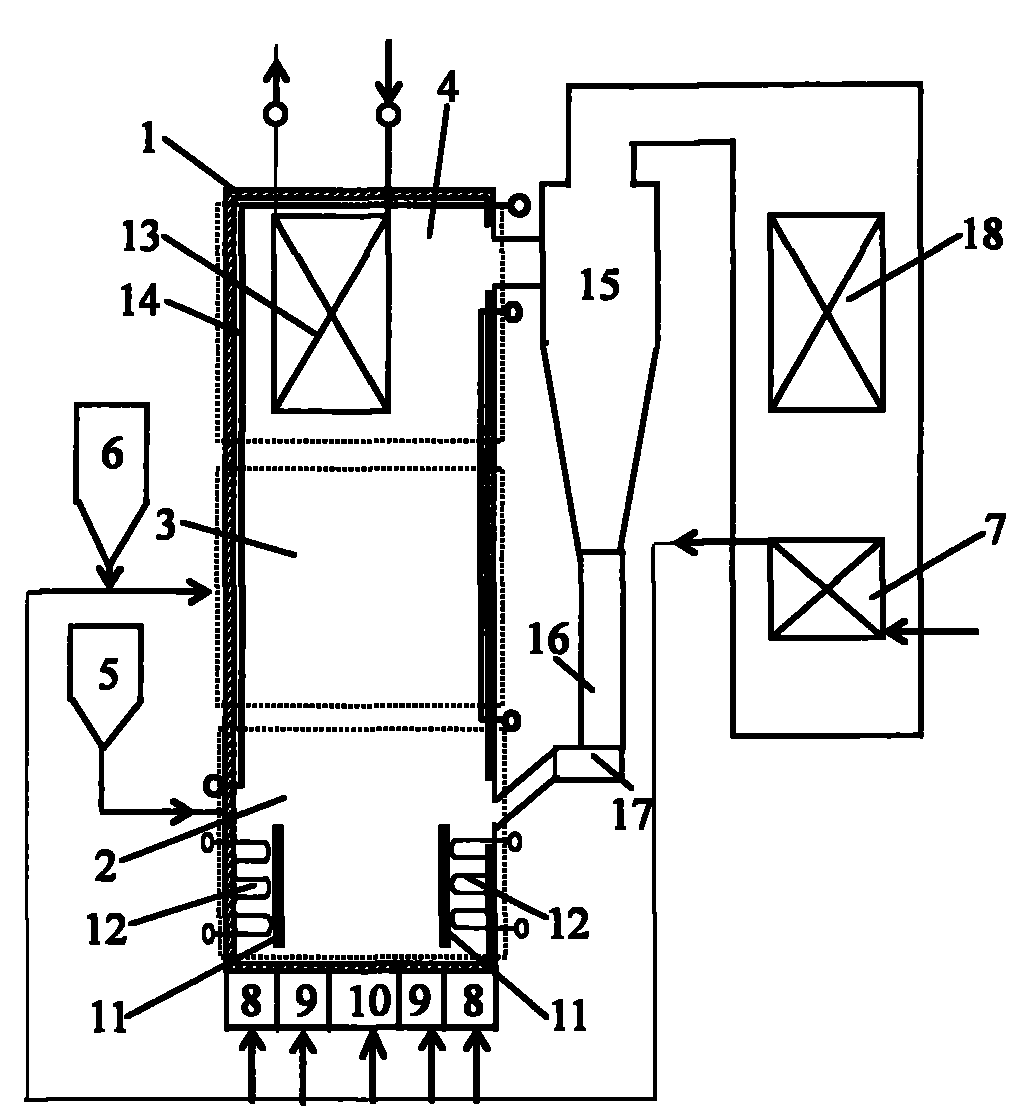

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the embodiment of the present invention provides a segmented high-temperature combustion circulating fluidized bed system, which is used for coal combustion with small particle size, gasification or organic waste incineration.

[0014] The system includes a furnace body and a fuel feeding system. The fuel feeding system includes a small particle size fuel feeding device 6 and a large particle size fuel feeding device 5. The large particle size fuel feeding device 5 is circulated and fluidized with the bottom of the furnace body. The bed combustion section 2 is connected to supply large particle size fuel to the circulating fluidized bed combustion section 2 at the bottom of the furnace body, and the small particle size fuel feeding device 6 is connected to the high temperature suspension combustion section 3 in the middle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com