Controlled release fertilizer with high content of biological carbon and preparation method thereof

A controlled-release fertilizer and bio-carbon technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of large waste of raw materials, single controlled-release mechanism, and inability to be directly applied, and achieve low production costs, flexible formula application, and energy saving The effect of raw materials and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

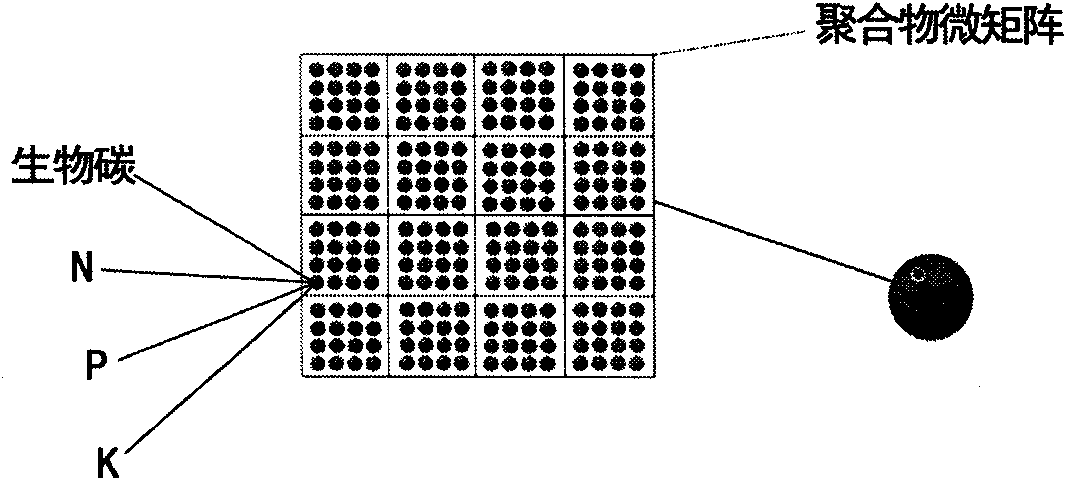

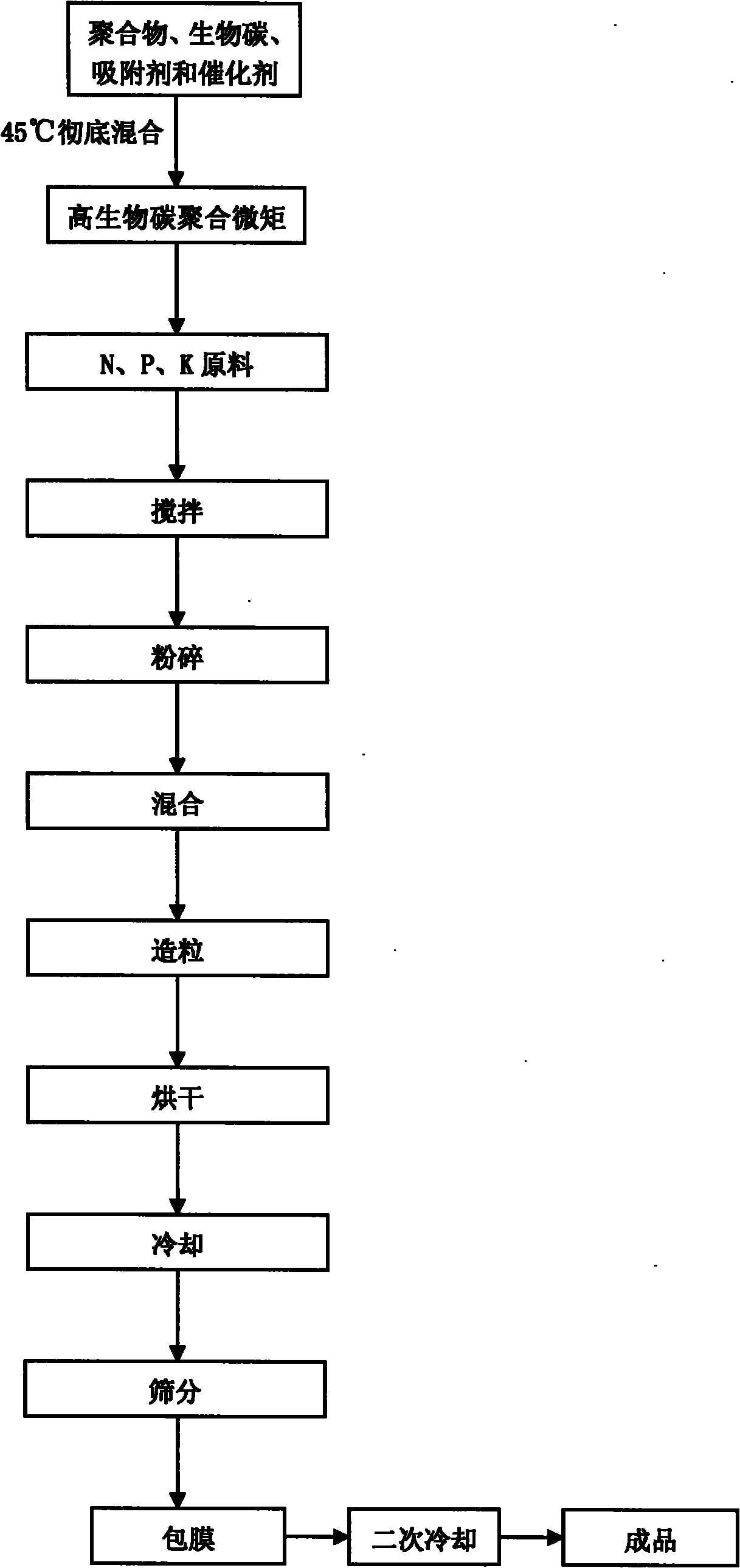

[0031] The preparation process of high biological carbon controlled release fertilizer is as follows: figure 2 As shown, it mainly includes two parts:

[0032] 1. Preparation of high biochar controlled release agent:

Embodiment 1

[0034] Polyvinyl alcohol, polyvinyl acetic acid, and carbonized formaldehyde cellulose are mixed in a weight ratio of 40:40:20 as polymer ingredients, and biochar produced by smokeless coking technologies such as orange stalks and calcium bentonite as an adsorbent are mixed at a ratio of 90: 10% by weight mixing; 0.1% by weight of polymer ingredients and 99% by weight of biochar and adsorbent mixture, and 0.9% by weight of catalyst propylene glycol are thoroughly mixed to make a high biochar slow-release agent, mixed granules The diameter is controlled at 80-100 mesh (grid), and the mixing temperature is 45-65°C.

Embodiment 2

[0036] The cellulose polymer ethlcellalose is used as the polymer batching, and the biochar produced by smokeless coking technologies such as orange stalks is mixed with the zeolite powder as the adsorbent in a 90:10 weight ratio; the polymer batching of 45% by weight and 54.98 % weight ratio of biochar and adsorbent mixture, and 0.02% weight ratio of catalyst ethylene glycol are thoroughly mixed to make high biochar slow-release agent, the particle size after mixing is controlled at 80-100 mesh (grid), mixed The temperature is 45-65°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com